Alkali-soluble resin, hydrogenated compound, method for producing hydrogenated compound, resin composition, cured film of resin composition, touch panel, and optical filter

A manufacturing method and soluble technology, which can be applied in the fields of optical filters, nonlinear optics, optics, etc., and can solve the problems of difficulty in taking into account light shielding and low reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

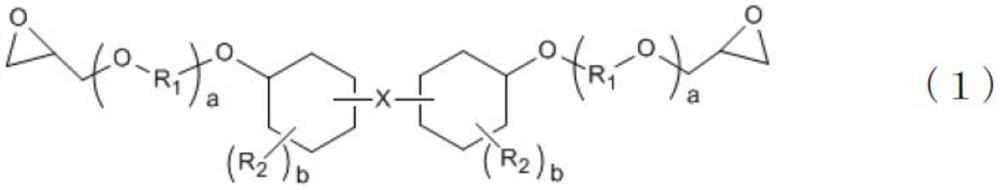

[0262] First, a synthesis example of a polymerizable unsaturated group-containing alkali-soluble resin having a structure represented by the general formula (2) and the general formula (15) will be described.

[0263] [Solid content concentration]

[0264] 1 g of the resin solution obtained in the synthesis example and the comparative synthesis example, the photosensitive resin composition, etc. were impregnated in a glass filter [mass: W 0 (g)], and weigh [W 1 (g)], use the following formula (1) to obtain the mass [W 2 (g)].

[0265] Solid content concentration (mass%) = 100 * (W 2 -W 0 ) / (W 1 -W 0 )(1)

[0266] [acid value]

[0267] Dissolve the resin solution in tetrahydrofuran, and titrate with a 1 / 10N-KOH aqueous solution using a potentiometric titration device "COM-1600" (manufactured by Hiranuma Sangyo Co., Ltd.), and use the amount of KOH required per 1 g of the solid content as the acid value .

[0268] [molecular weight]

[0269]For colloid permeation chro...

Synthetic example 1

[0281] Add the 50% PGMEA solution (329.1g) of HBPA-EA1, BPDA (44.1g), THPA (22.8g), TEAB (0.43g), PGMEA (8.5g) in the 1000ml four-neck flask with reflux cooler, Stir at 120 to 125° C. for 6 hours to obtain alkali-soluble resin (i)-1 (solid content concentration: 61.2% by mass, weight average molecular weight (Mw): 3210, acid value (solid content conversion): 123.1 mgKOH / g) .

Synthetic example 2

[0283] Add the 50% PGMEA solution (340.0g), HPMDA (34.7g), THPA (23.6g), TEAB (0.43g), PGMEA (8.5g) of HBPA-EA1 in the 1000ml four-necked flask that attaches reflux cooler, in It stirred at 120 to 125 degreeC for 6 hours, and obtained alkali-soluble resin (i)-2 (solid content concentration: 61.1 mass %, weight average molecular weight (Mw): 3230, acid value (solid content conversion): 120.4 mgKOH / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar absorption coefficient | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com