Method for separating ethyl ester toluene organic waste liquid containing small amount of water

An organic waste liquid, ethyl ester toluene technology, applied in organic chemistry, chemical instruments and methods, distillation purification/separation and other directions, can solve the problems of solvent pollution, equipment size and energy consumption increase, and achieve easy recovery, compact equipment, The effect of easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

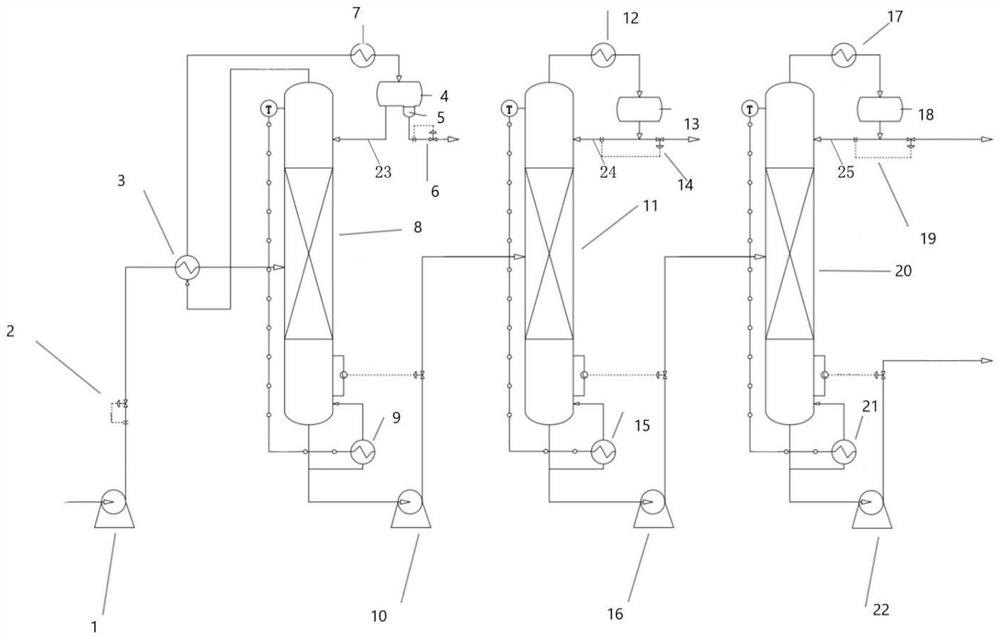

[0028] A kind of ethyl ester toluene organic waste liquid separation system containing a small amount of water, see figure 1 , including feed pump 1, dehydration tower 8, toluene-ethyl ester separation tower 11 and toluene purification tower 20 connected in sequence, organic waste liquid flows through dehydration tower 8, toluene-ethyl ester separation tower 11 successively through feed pump 1 and toluene purification tower 20;

[0029] The bottom of the dehydration tower 8 is provided with a first heater 9, and the mixed organic waste liquid at the bottom of the tower circulates through the pump in the first heater 9 to obtain heat so that it is partially vaporized and enters the dehydration tower 8; the top of the dehydration tower 8 is connected in turn The feed preheater 3, the first condenser 7 and the first condensate buffer tank 4, the bottom side of the first condensate buffer tank 4 are provided with a protruding water distribution bag 5, and the bottom of the water s...

Embodiment 2

[0040] Utilize the ethyl ester toluene organic waste liquid separation system containing a small amount of water of embodiment 1, the present invention provides a kind of ethyl ester toluene organic waste liquid separation method containing a small amount of water, wherein, in the organic waste liquid, water content is 2wt%, toluene The content is 53.4%, the ethyl ester content is 44%, and the heavy component impurities are 0.6%; specifically include:

[0041] Step 1: Pump the ethyl toluene ester water organic waste liquid into the dehydration tower, the amount of entering the tower is 1200kg / h, and then heat it to ensure that the temperature at the top of the tower is 72°C, the temperature of the liquid at the bottom of the tower is 84°C, and the evaporation at the top of the dehydration tower is The weight ratio to the feed amount is 1.5-2.5; the liquid in the dehydration tower is continuously vaporized, water and a small amount of organic matter are evaporated, and the laten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com