Device and method for promoting aerobic sludge granulation by combining magnetic material with moving magnetic field

A technology for moving magnetic fields and magnetic materials, applied in the directions of magnetic materials, chemical instruments and methods, magnetic objects, etc., can solve the problems of accelerating sludge granulation and other problems, and achieve the effect of promoting granulation, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

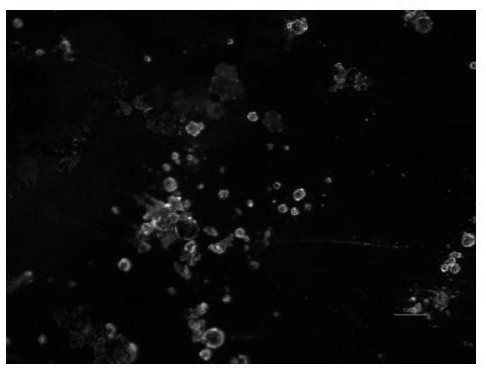

Image

Examples

Embodiment 1

[0041] A method for promoting the rapid formation of aerobic granular sludge by using a magnetic material combined with a moving magnetic field, comprising the following steps:

[0042] 1) Take 3L of ordinary activated sludge cultivated in the laboratory in the reactor, and the sludge concentration is 2g / L;

[0043] 2) Set up a periodic operation program in the reactor in step 1), and operate according to water inflow (10min), aeration (180min), sedimentation (3min), water outflow (2min), and idleness (45min), and the water filling ratio is 50 %;

[0044] 3) When the reactor in step 2) is running to the water inflow stage, add 1.2g of magnetic chitosan, and then add another 1.2g after 24 hours for 5 days, with a total of 6g (100% of the dry sludge mass) %);

[0045] 4) After the reactor in step 3) runs to the end of the aeration stage of each cycle for 30 minutes, the pH automatic adjustment program is automatically started, and the pH of the reactor is adjusted to about 6.0...

Embodiment 2

[0049] A method for promoting the rapid formation of aerobic granular sludge by using a magnetic material combined with a moving magnetic field, comprising the following steps:

[0050] 1) Take 3L of ordinary activated sludge cultivated in the laboratory in the reactor, and the sludge concentration is 1.5g / L;

[0051] 2) Set up a periodic operation program in the reactor in step 1), and operate according to water inflow (10min), aeration (180min), sedimentation (3min), water outflow (1.5min), idle (45.5min), water filling ratio 50%;

[0052] 3) When the reactor in step 2) is running to the water inflow stage, add 1.5g of magnetic chitosan, and then add another 1.5g after 24 hours for 3 days, with a total of 4.5g (dried sludge mass) 120%);

[0053] 4) After the reactor in step 3) runs to the end of the aeration phase of each cycle for 30 minutes, the pH automatic adjustment program is automatically started, and the pH of the reactor is adjusted to about 6.0 for 8 days;

[00...

Embodiment 3

[0057] A method for promoting the rapid formation of aerobic granular sludge by using a magnetic material combined with a moving magnetic field, comprising the following steps:

[0058] 1) Take 3L of ordinary activated sludge cultivated in the laboratory in the reactor, and the sludge concentration is 1.6g / L;

[0059] 2) Set up a cycle operation program in the reactor in step 1), and operate according to water inflow (10min), aeration (180min), sedimentation (3min), water outflow (3min), and idleness (44min), and the water filling ratio is 50 %;

[0060] 3) When the reactor in step 2) runs to the water inflow stage, add 0.336g of magnetic chitosan, add 0.336g again after 24h, and continue for 10 days, with a total of 3.36g (dry sludge mass) 70%);

[0061] 4) When the reactor in step 3) runs to the end of the aeration phase of each cycle for 30 minutes, the pH automatic adjustment program is automatically started, and the pH of the reactor is adjusted to about 6.0 for 15 days...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com