Injection mould with water blowing device

An injection mold and mold technology, applied in the field of injection molds with a water blowing device, can solve the problems that the water tank cannot be blown, the water in the water tank cannot be completely blown, and rust, etc., to achieve acceleration, reduce consumption, and avoid production. rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

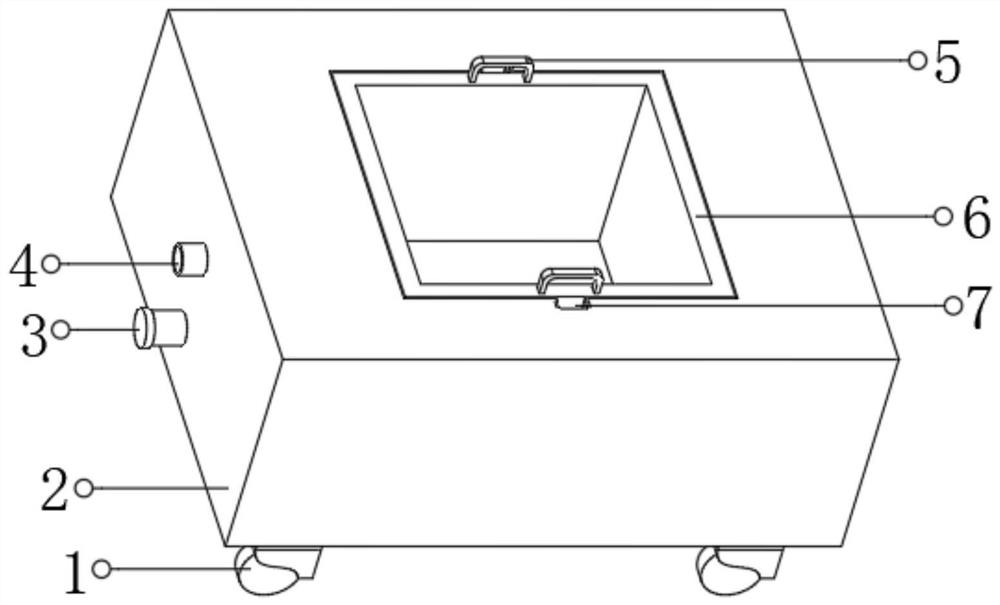

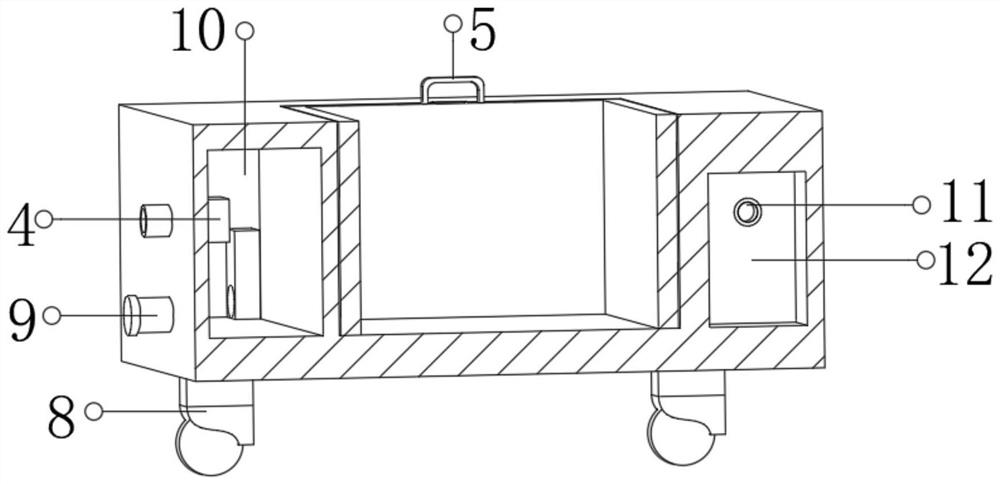

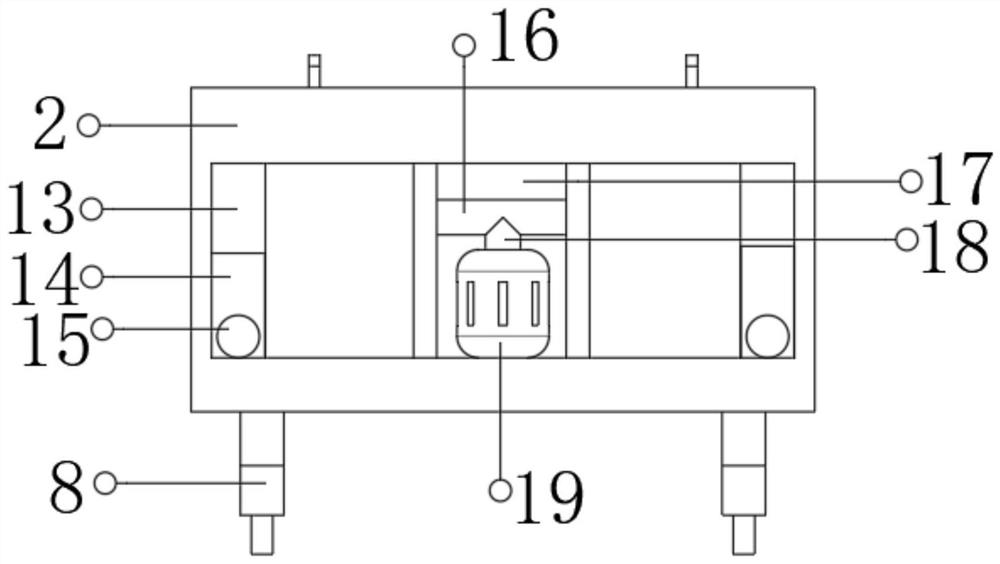

[0026] refer to Figure 1-3 , an injection mold with a water blowing device, including a mold body 2, a groove is opened on the outer wall of the top of the mold body 2, and chute 7 is opened on the inner wall at both ends of the groove, and the outer walls of the two chute 7 slide A mold cavity 6 is connected, a water storage tank 10 is arranged inside one end of the mold body 2, a water tank 13 is opened inside the two ends of the mold body 2, and a water retaining plate 14 is arranged between the water tank 13 and the water storage tank 10, two water retaining plates 14 The height is lower than the inner wall of the top of the water tank 13, and a round hole 15 is opened on the outer wall of the two water baffles 14 near the bottom, and the outer wall of one side of the two water tanks 13 is connected with a riser 12 by bolts, and the riser 12 There is an air inlet 11 on the surface, an air pressure box 17 is arranged between the two vertical plates 12, and the inner wall o...

Embodiment 2

[0030] refer to Figure 4 , an injection mold with a water blowing device. Compared with Embodiment 1, the two ends of the top outer wall of the mold body 2 are connected with pillars 23 by bolts, and the top outer walls of the pillars 23 are connected with a top plate 21 by bolts. The bottom outer wall of the top plate 21 is connected with an electric telescopic rod 22 by bolts, and the bottom outer wall of the electric telescopic rod 22 is connected with a limit rod 20 by bolts.

[0031] Working principle: When in use, when in use, first add an appropriate amount of water into the water storage tank 10 through the water inlet pipe 4, and the water in the water storage tank 10 flows into the two water tanks 13 through the round hole 15 on the water retaining plate 14, when injection molding When the volume of the model is relatively large, a large amount of water can be injected to make the water overflow directly from the upper part of the water baffle 14, so that the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com