Efficient pipe chase machine and pipe machining method

A pipe groove machine, an efficient technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as poor matching and low processing efficiency, and achieve the effect of expanding storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

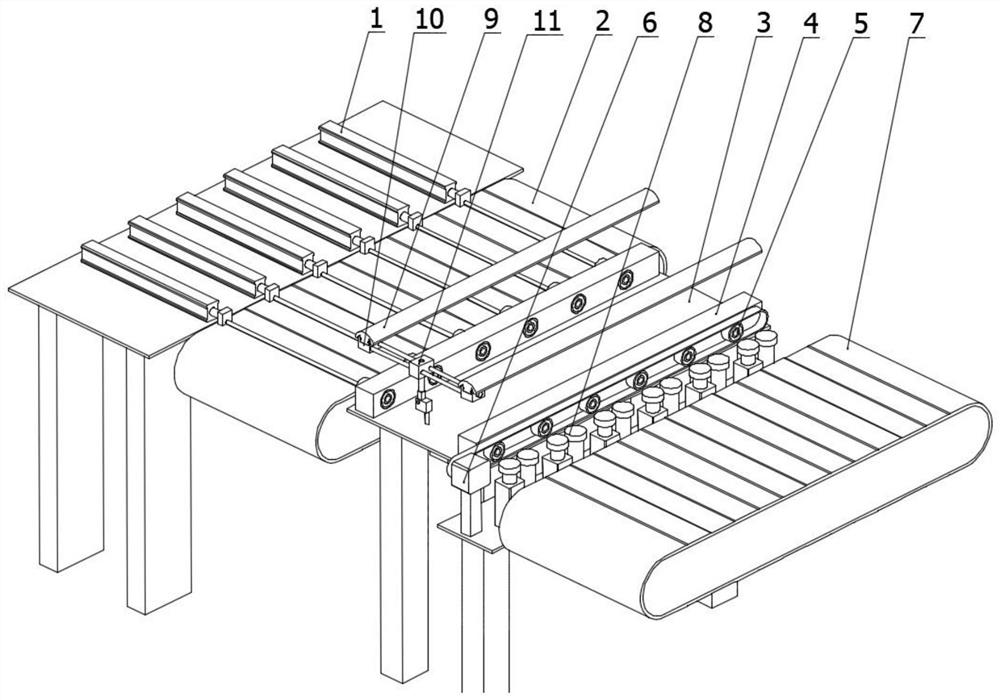

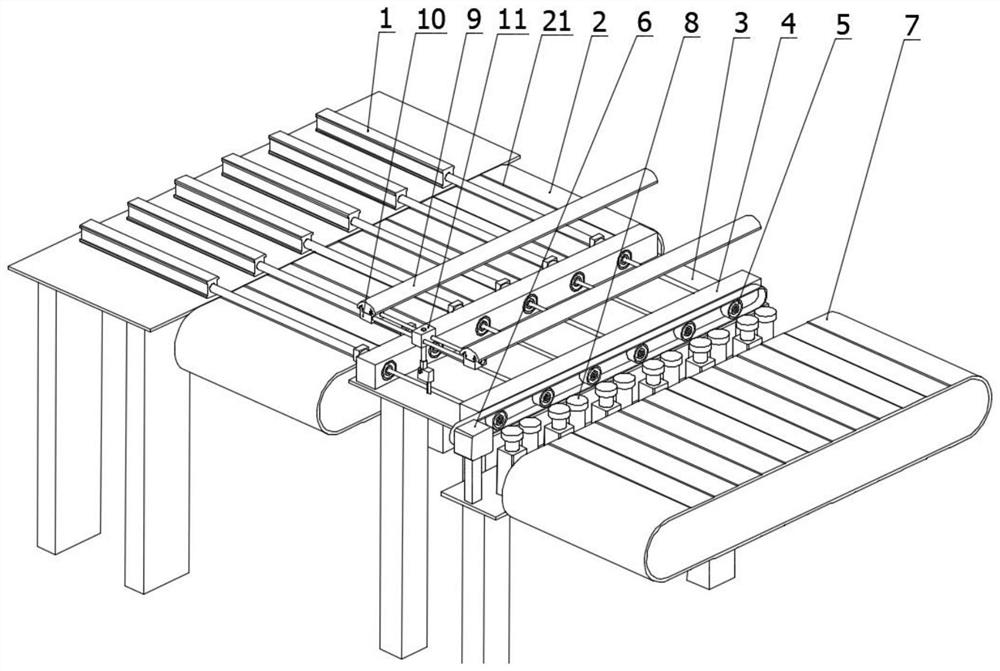

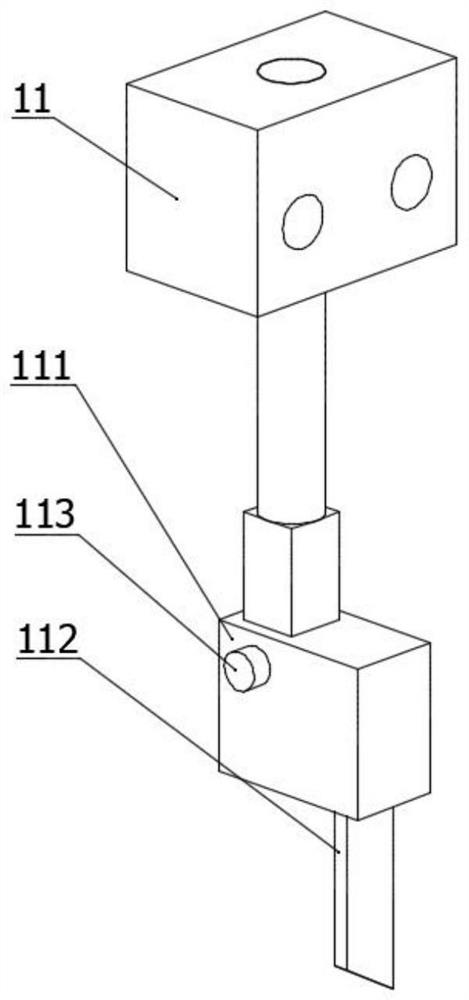

[0077] A high-efficiency pipe groove machine, wherein, such as figure 1 , 2 As shown, it includes: a pushing device 1 , a first conveying mechanism 2 , a rotating clamping mechanism 3 , a rotating device 6 , a displacement part 10 , a sliding block 11 , a set 111 , and a second conveying mechanism 7 .

[0078] The pushing device 1 can move freely telescopically. The first transfer mechanism 2 is in the right end position of the push mechanism.

[0079] The rotating clamping mechanism 3 is located at the right end of the first conveying mechanism 2 , and the rotating clamping mechanism 3 includes a mounting seat 4 , a bearing (not shown), and a clamping assembly 5 . There are at least two mounting seats 4 , the mounting seats 4 have accommodating spaces, and the accommodating spaces between the mounting seats 4 are aligned with each other. The bearing is provided in the accommodating space.

[0080] The clamping assembly 5 is arranged in the bearing, such as Figure 4-7 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com