Novel oily flue gas adsorption treatment device and use method

An adsorption treatment and flue gas technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of affecting treatment effect and efficiency, inconvenient replacement of filter elements, cleaning, complex structure, etc., to avoid insufficient adsorption and purification. , The effect of extending the flue gas flow path and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

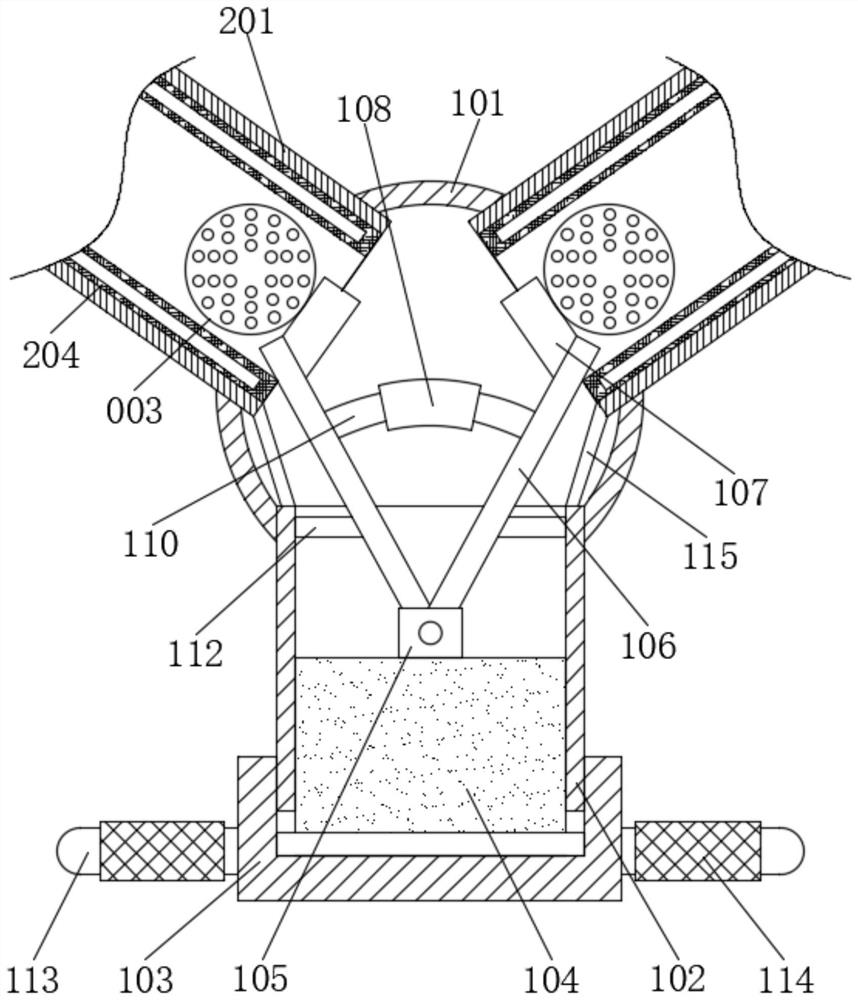

[0045] see Figure 1-3 , a new type of oily fume adsorption treatment device, including a transfer spherical shell 101, two symmetrically arranged adsorption pipes 201 are connected to the outer wall of the transfer spherical shell 101, the adsorption pipes 201 are arranged obliquely, and the adsorption pipes 201 are far away from the transfer spherical shell 101 One end of the transfer spherical shell 101 is higher than the end close to the transfer spherical shell 101, so that the device as a whole is in the shape of a V-shaped pipe, which can prolong the path of the flue gas flow, thereby making the adsorption more sufficient. The outer wall of 102 is screwed with a matching pipe cover 103, and the inner wall of the pipe cover 103 is rotatably connected with a pipe plug 104 that matches the outlet pipe 102. The top of the pipe plug 104 is fixedly connected with a hinged seat 105, which The inside of 105 is hinged with two diagonal bars 106 arranged crosswise, and the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com