Method for adjusting process parameters in polyester fiber polymerization process

A polyester fiber and process parameter technology, which is applied in the field of process parameter adjustment, can solve problems such as inaccuracy, untimeliness, and inability to accurately adjust process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

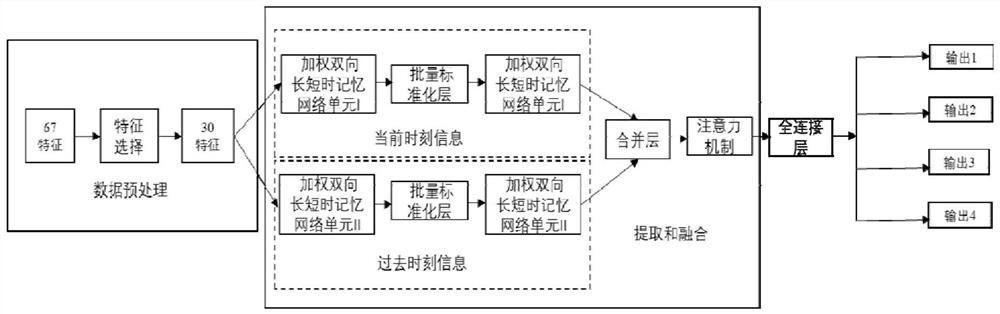

[0198] A method for adjusting process parameters in the polyester fiber polymerization process, the steps are as follows:

[0199] (1) collect m characteristic data, and characteristic data is the technological parameter data relevant with polyester fiber performance index;

[0200] Such as Figure 4 As shown, the polyester fiber polymerization process mainly includes three stages, namely esterification process, pre-condensation process and final polycondensation process. The research of the present invention is mainly aimed at the currently widely used DuPont three-pot process. Formic acid (Polyterephthalic acid, PTA) and ethylene glycol (Ethylene glycol, EG) are mixed in a certain ratio in the slurry mixing tank, and then the mixed slurry is continuously fed into the esterification reaction tank from the slurry feeding tank, Under the action of a certain temperature and pressure, the raw materials produce oligomers through chemical reactions, and then the oligomers are cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com