Intelligent carbon density instrument

A density meter, stainless steel technology, applied in the field of intelligent carbon density meter, can solve the problems of not being able to take samples at any time, low accuracy, ore slurry splashing, and achieve the effects of reducing labor intensity, convenient installation and maintenance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

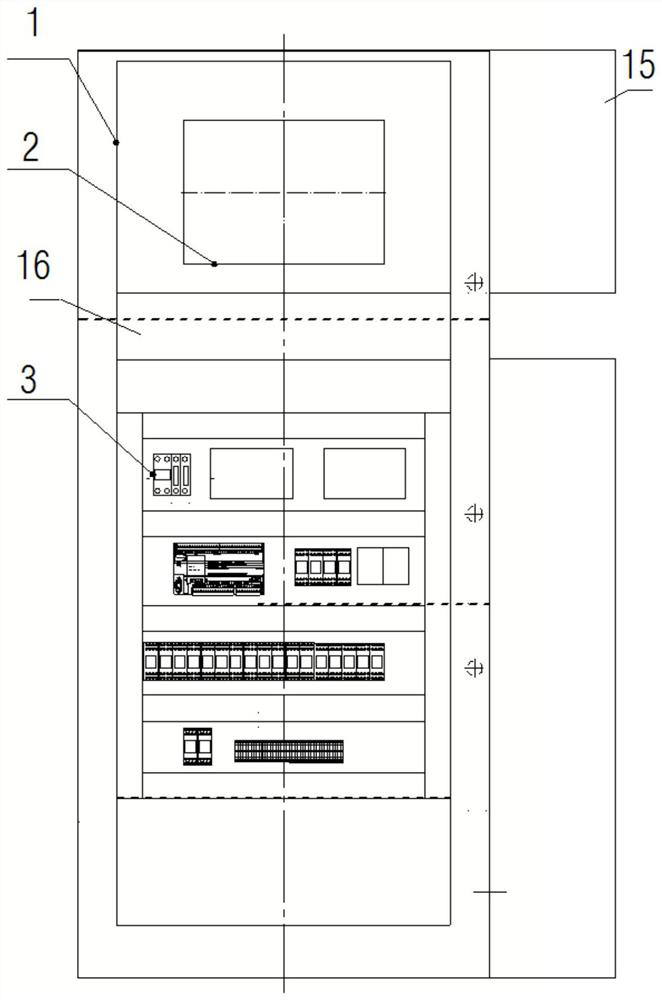

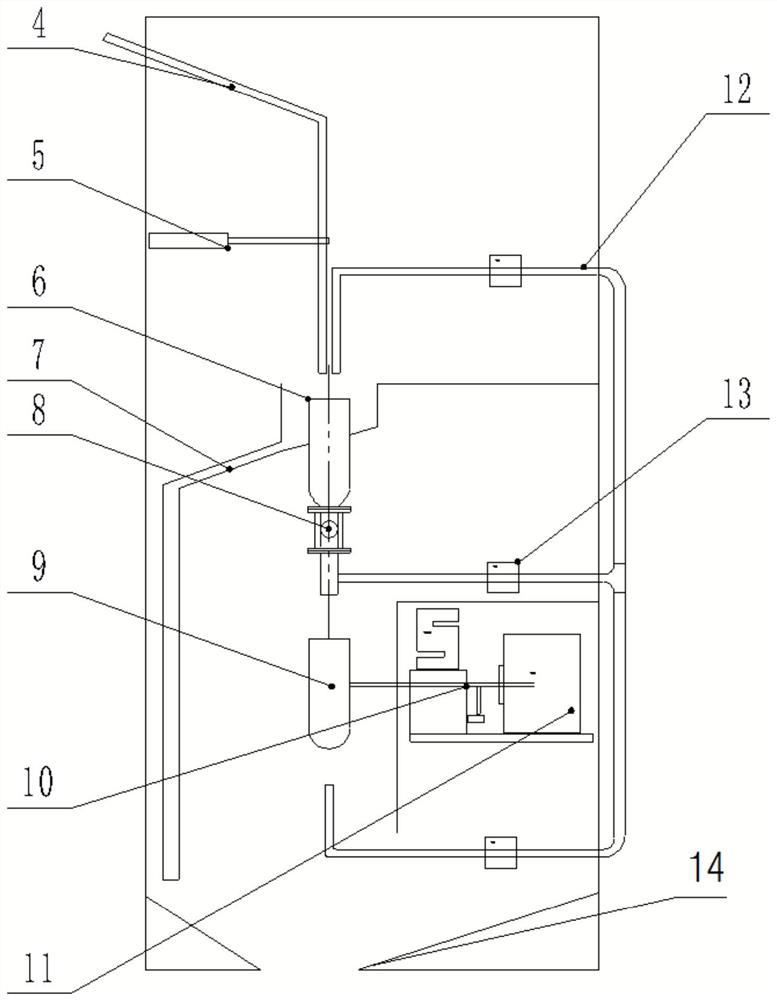

[0029] see Figure 1-2 , the present invention provides a technical solution: an intelligent carbon density meter, including a stainless steel box 1, the front and rear sides of the stainless steel box 1 are provided with operation doors 15, the upper and lower parts of the front side of the stainless steel box 1 A touch screen 2 and an electrical control combination panel 3 are provided respectively, a partition 16 is provided between the touch screen 2 and the electrical control combination panel 3, a sampling tube 4 is provided on the upper part of the inner cavity of the stainless steel box body 1, and one side of the inner wall of the stainless steel box body 1 An electric push rod 5 is installed on the wall, and the telescopic end of the electric push rod 5 is connected with the outer wall of the sampling tube 4. The top of the sampling tube 4 extends out of the stainless steel box 1, and a sampling tube is arranged below the bottom of the stainless steel box 1. Scoop 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com