Submerged arc furnace equipment for producing macrocrystalline fused magnesite

A technology for fused magnesia and submerged arc furnace, applied in lighting and heating equipment, electric furnace heating, furnace safety devices, etc., can solve the problems of dust drift and other problems, and reduce labor intensity, feeding labor intensity and personal safety risks The effect of reducing, reducing power demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

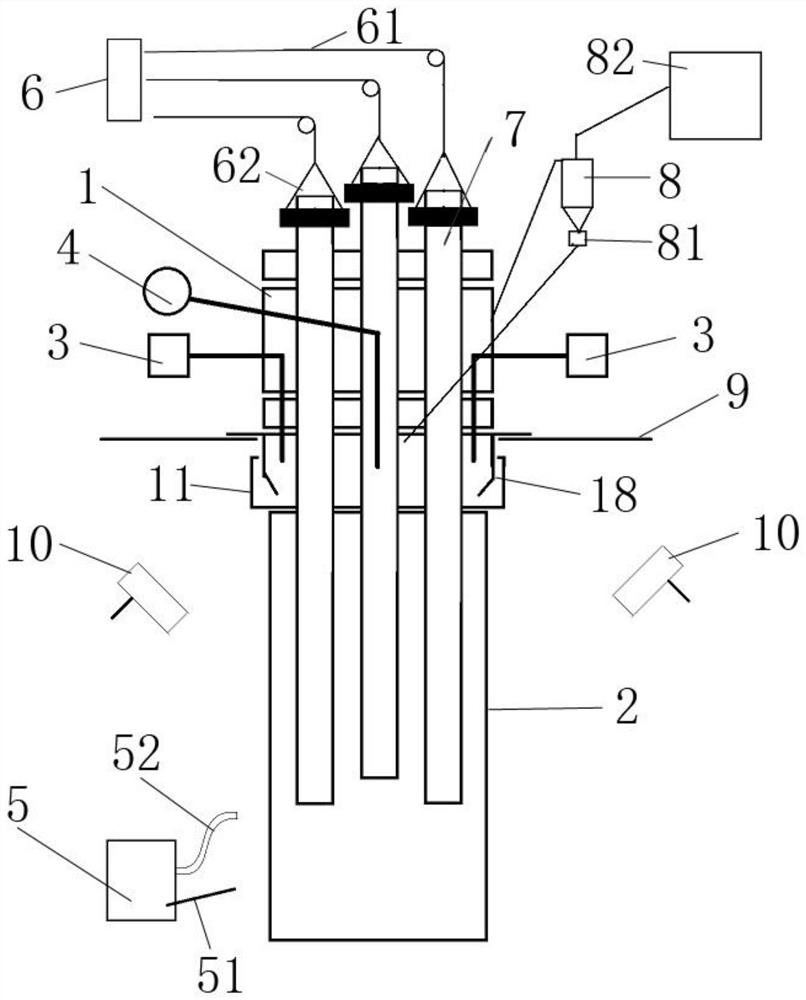

[0034] Such as figure 1 As shown, the submerged arc furnace equipment for producing large crystal fused magnesia includes a submerged arc furnace barrel 2, a furnace cover system 1, a material input system 3, a crushed electrode conveying system 4 and a dust removal and return system. The furnace cover System 1 is installed at the upper opening of the submerged arc furnace barrel, and a material input system 3 and a crushed electrode conveying system 4 are installed on the furnace cover system 1. The discharge pipe of the material input system 3 passes through the furnace cover system 1 to reach On the outside of any electrode, the discharge pipe of the crushed electrode conveying system 4 passes through the furnace cover system 1 to reach the central part surrounded by three electrodes. The furnace cover system 1 is provided with a dust removal pipeline, and the dust removal pipeline is connected with the The dust removal and return system is connected.

[0035] The furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com