Liquid spraying screw rod compressor system

A screw compressor and compressor technology, applied in the field of compressors, can solve the problems of high current of the air compressor motor, dead contacts burning, blockage of the oil separation core, etc., to achieve the effect of improving precise separation, avoiding deviation, and cleaning friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

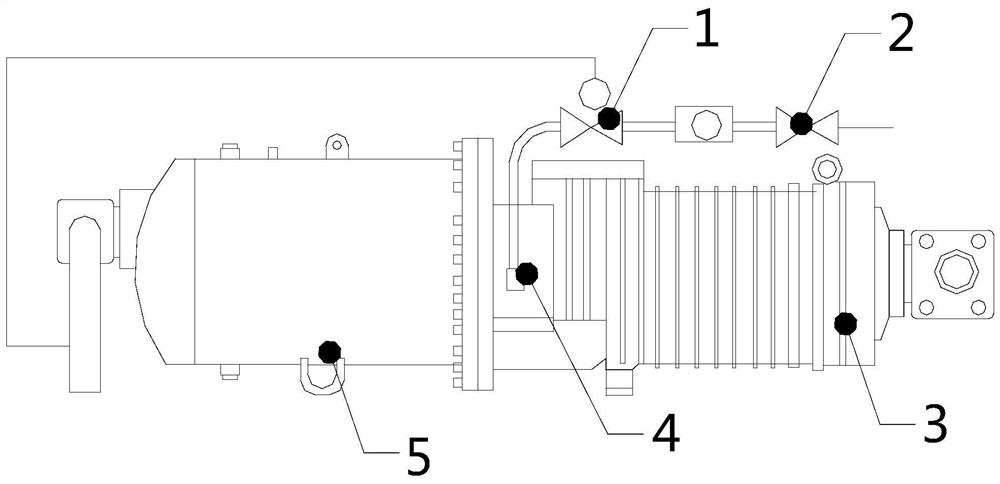

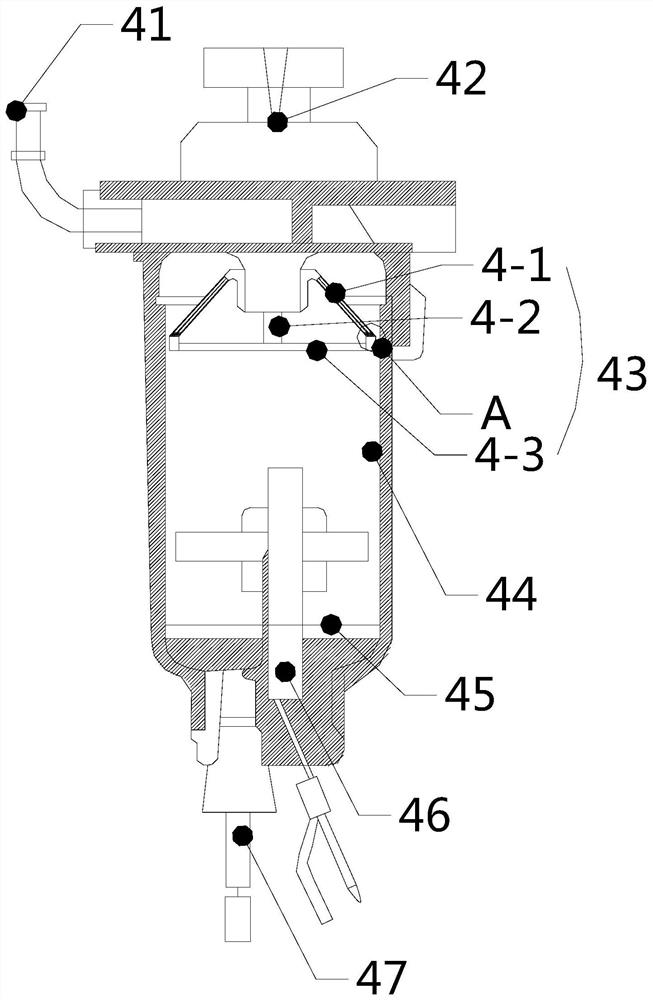

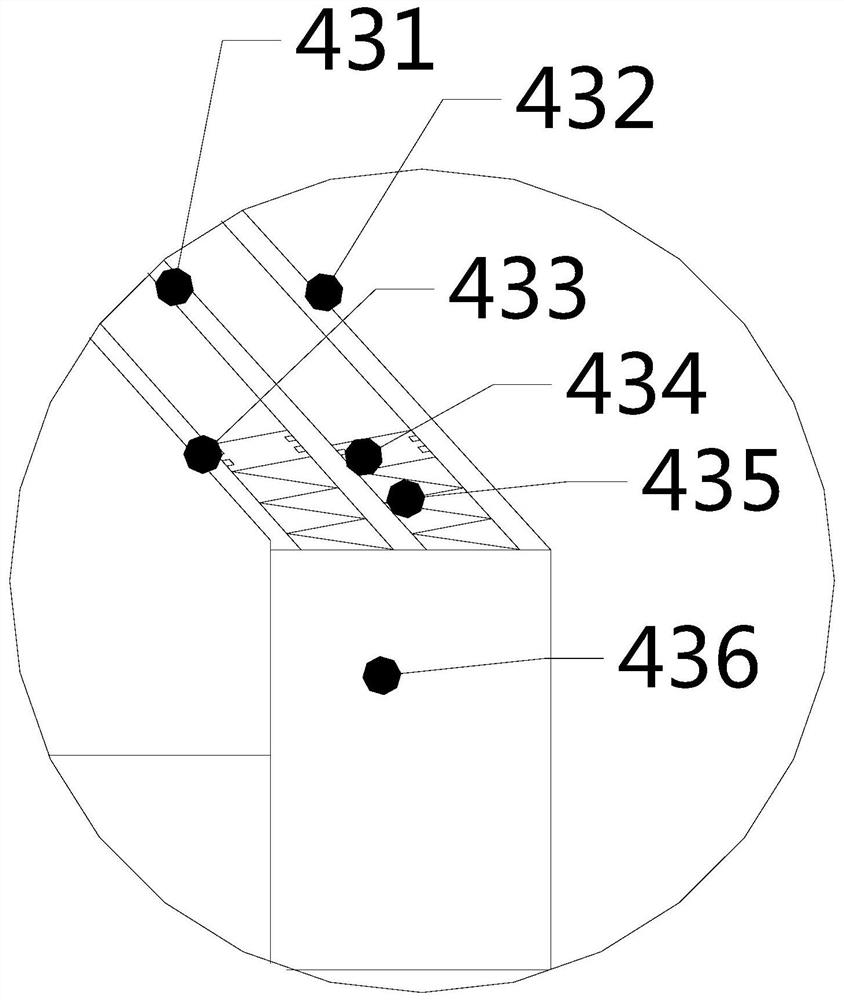

[0024] see Figure 1-Figure 4 , a liquid spraying screw compressor system, the present invention provides a liquid spraying screw compressor system, its structure includes a first valve 1, a second valve 2, a screw 3, an oil separator 4, a compressor 5, the compression The machine 5 is mechanically connected to the screw 3 through a shaft, and an oil separator 4 is installed at the position where the screw 3 is mechanically connected to the compressor 5, and the oil separator 4 is mechanically connected through the first valve 1, the second valve 2 and the condenser. connection, the first valve 1 is mechanically connected to the compressor 5 through pipelines, and the oil separator 4 includes an oil outlet 41, a manual diaphragm pump 42, an oil inlet, an oil separator core 43, a valve body 44, and a float 45 , a liquid level sensor 46, a drain plug 47, the top of the valve body 44 is equipped with a hand-pressed diaphragm pump 42, and the horizontal ends of the valve body 44 b...

Embodiment 2

[0032] see Figure 1-Figure 4 , a liquid spraying screw compressor system, the present invention provides a liquid spraying screw compressor system, its structure includes a first valve 1, a second valve 2, a screw 3, an oil separator 4, a compressor 5, the compression The machine 5 is mechanically connected to the screw 3 through a shaft, and an oil separator 4 is installed at the position where the screw 3 is mechanically connected to the compressor 5, and the oil separator 4 is mechanically connected through the first valve 1, the second valve 2 and the condenser. connection, the first valve 1 is mechanically connected to the compressor 5 through pipelines, and the oil separator 4 includes an oil outlet 41, a manual diaphragm pump 42, an oil inlet, an oil separator core 43, a valve body 44, and a float 45 , a liquid level sensor 46, a drain plug 47, the top of the valve body 44 is equipped with a hand-pressed diaphragm pump 42, and the horizontal ends of the valve body 44 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com