Pressure control sliding sleeve

A technology of pressure control and sliding sleeve, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., and can solve problems such as breakage, difficult operation and high operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

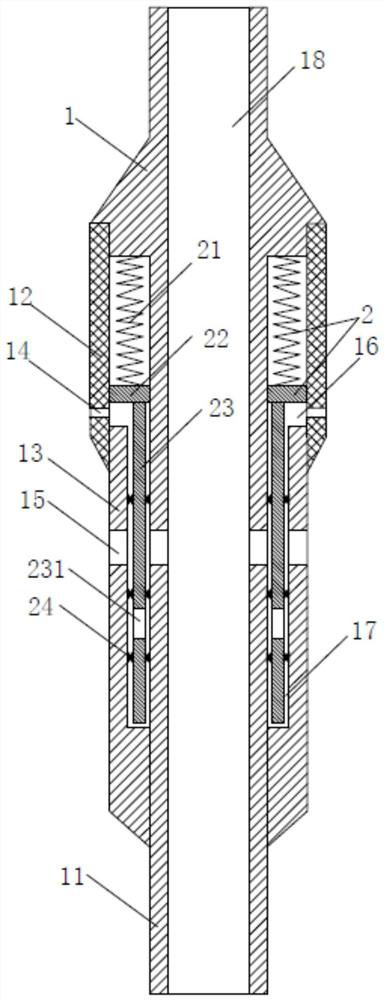

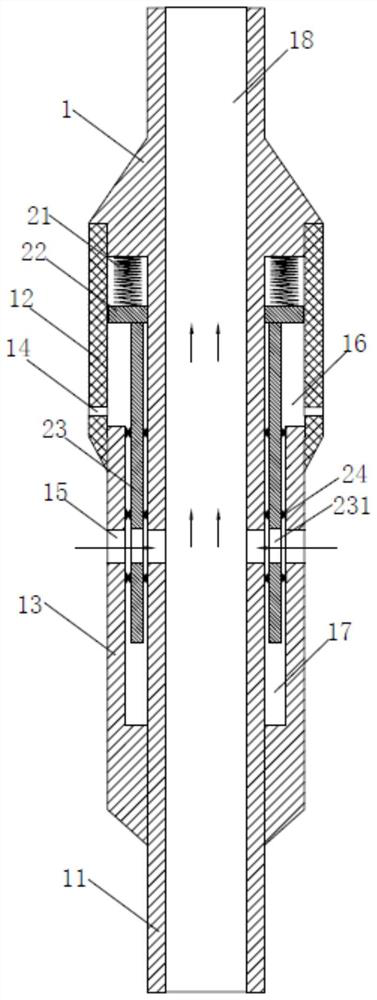

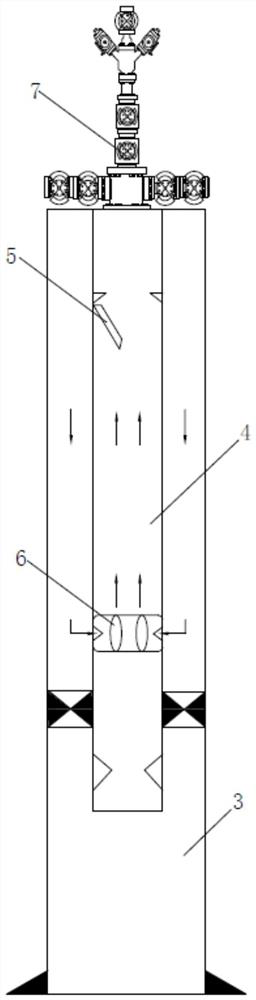

[0020] This embodiment relates to a pressure control sliding sleeve, such as figure 1 As shown, it includes: sliding sleeve body 1 and hydraulic control switch 2. Wherein, the sliding sleeve body 1 is provided with a hydraulic hole 14 and a liquid inlet hole 15 . The hydraulic hole 14 communicates with the annular space 3 and the hydraulic control switch 2 , and the liquid inlet hole 15 communicates with the annular space 3 , the inner cavity of the sliding sleeve body 1 and the hydraulic control switch 2 . The hydraulic control switch 2 is movably assembled in the sliding sleeve body 1, and the hydraulic control switch 2 is used to open or close the liquid inlet hole 15 according to the change of the external hydraulic pressure. By controlling the pressure in the annular space 3 to control the opening or closing of the sliding sleeve, it not only saves operation time and cost, thereby reducing the time and cost of oil field development, but also reduces the difficulty of ope...

Embodiment 2

[0026] The main difference between this embodiment and Embodiment 1 is that the sliding sleeve body 1 includes: an inner shell 11 and an upper shell 12 , the upper shell 12 is partly sleeved outside the inner shell 11 , and one end thereof is fixedly assembled on the inner shell 11 . The cavity 16 is disposed between the inner shell 11 and the upper shell 12 . The hydraulic hole 14 is arranged on the upper shell 12 , the liquid inlet hole 15 is arranged on the inner shell 11 , and both the hydraulic hole 14 and the liquid inlet hole 15 communicate with the cavity 16 .

[0027] The hydraulic control switch 2 includes: an elastic member 21 and a piston 22 . The elastic member 21 is assembled in the cavity 16 . The piston 22 is movably assembled in the cavity 16 , located between the hydraulic hole 14 and the liquid inlet hole 15 , and one end thereof abuts against the elastic member 21 . The piston 22 reciprocates linearly in the cavity 16 under the action of the external hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com