A permanent repair method for broken strands of optical fiber composite overhead ground wire

A composite technology of overhead ground wire and optical fiber, applied in the direction of overhead line/cable equipment, etc., can solve problems affecting optical fiber communication, achieve the effects of saving investment, eliminating hidden dangers in operation, and ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

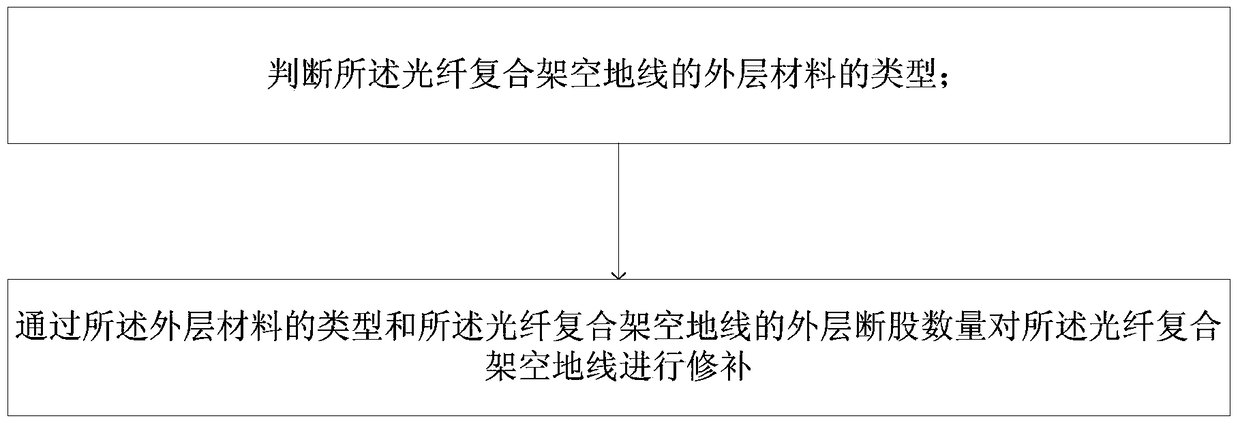

[0050] Such as figure 1 As shown, the invention of this example

[0051] (1) The outer layer is an aluminum alloy single wire OPGW broken strand repair method

[0052] The typical structure of OPGW (OPGW-24B1-145[87.3; 178]) whose outer layer is an aluminum alloy single wire is used as an example to analyze the research on the threshold of broken strand repair. The bearing area and strength analysis of broken strands are shown in Table 1.

[0053] Table 1 Analysis of bearing area and strength of broken strands of OPGW-24B1-145[87.3; 178]

[0054]

[0055]

[0056] According to the analysis in Table 1, the OPGW broken strand repair plan with the outer layer of aluminum alloy single wire is as follows: if the outer layer is broken 1-2 strands, it can be repaired with aluminum-clad steel repair strips; if the number of outer layer broken strands is greater than 2 strands, it is recommended to temporarily Replace OPGW after patching.

[0057] (2) The outer layer is 40% c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com