Immersive sprinkling-type feather and down feather washing device with low bath ratio and washing method

A low-bath-ratio immersion and down washing technology, applied in the field of down washing, can solve the problems of oxygen consumption, cleanliness, excessive microorganisms, damage to the user's health, and incomplete decontamination, etc., to achieve better washing effect , Thorough decontamination, improved uniformity of decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] First start the water pump one 50 in the water supply and drainage system 5, close the sewage pipe 53, add clear water to the washing drum 3 through the external water source inlet pipe 51 and the water outlet pipe 52, and close the water pump one 50; agent, deodorant, bactericide; then start the motor 60, the motor 60 drives the outer face gear 62-1 and the inner face gear 62-2 to rotate simultaneously through the reducer 61 and the main shaft 62, and the gear one 64-1 and the gear two 65- 1 rotates clockwise, gear three 66-1 and gear four 67-1 rotate counterclockwise, shaft one 64 rotates clockwise with paddle one 6-1, shaft two 65 rotates paddle two 6-2 clockwise, Rotating shaft 3 66 rotates counterclockwise with paddle 3 6-3, and rotating shaft 4 67 rotates counterclockwise with paddle 4 6-4 to stir degreaser, detergent, deodorant, bactericide and clear water evenly; Figure 16 As shown, wherein, the counterclockwise rotating blade three 6-3 and paddle four 6-4 cons...

Embodiment 2

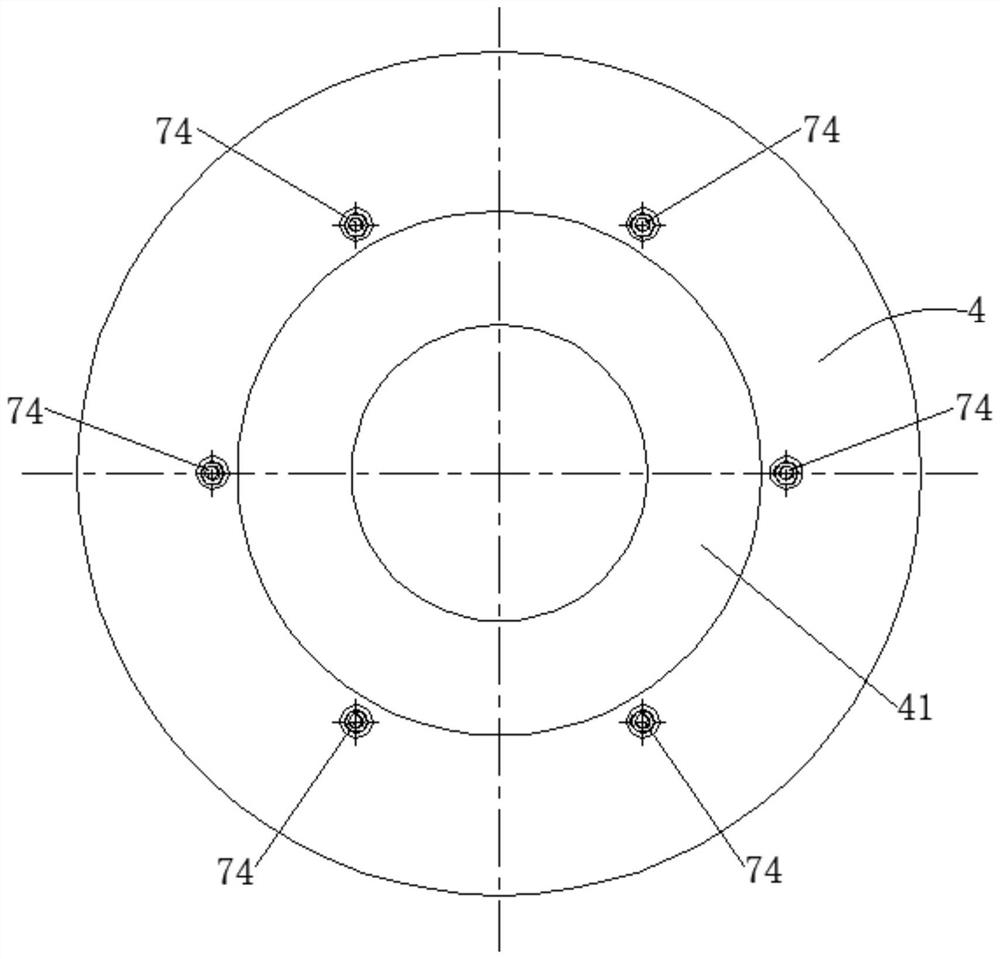

[0092] On the basis of Example 1, the bottom plate 2 is provided with a water inlet 20 and a water outlet 21, and a hemispherical mesh cover is provided on the water inlet 20 and the water outlet 21, so as to avoid accumulation of feathers caused by a flat mesh In the event of blockage, the hemispherical net cover is not easy to be blocked by messy down materials to be washed, which ensures the stable operation of the equipment; the washing cylinder 3 is a cylindrical tube with micropores, so that the down materials to be washed are bound in the In the washing cylinder 3, the washing liquid can enter between the washing cylinder 3 and the outer cylinder 4 through the micropores, realizing the circulation and soaking of the washing liquid; the lower end of the outer cylinder 4 is provided with a plurality of circulating water ports 40 in the circumferential direction, so that A plurality of hemispherical interfaces 70-1 are arranged on the circumferential direction of the upper ...

Embodiment 3

[0096] Take two parts of 500g Wanxi white goose raw material cashmere (with 95% cashmere content), and wash them with soaking and immersion washing machines respectively. The bath ratio of the shower type is 1:30, and the same amount of water is used for 6 rinses; the ratio of the immersion type fine bath is 1:60, and the same amount of water is used for rinsing 13 times. The post-dehydration and drying processes are the same.

[0097] The detergent components added in the two washing processes are the same, specifically as follows: 1.0% degreasing agent; 0.8% deodorant; 2.0% fine detergent.

[0098] The performance indicators of washed Wanxi white goose raw material down were tested according to GB / T 10288-2016 "Down and Feather Inspection Method". Three sets of experiments were carried out in parallel for each process, and the average value was taken. The results are shown in Table 1.

[0099] It can be seen from the data in Table 1 that the lower the dust content, the bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com