Plasmid DNA alkali cracking equipment and use method thereof

A technology of alkaline lysis and plasmids, which is applied in the direction of DNA preparation, biochemical equipment and methods, recombinant DNA technology, etc., can solve the problems of increasing production costs, not being able to shorten the production cycle, and not being able to achieve continuous bacterial resuspension, so as to shorten production cycle, increase production cost, and facilitate the effect of neutralization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

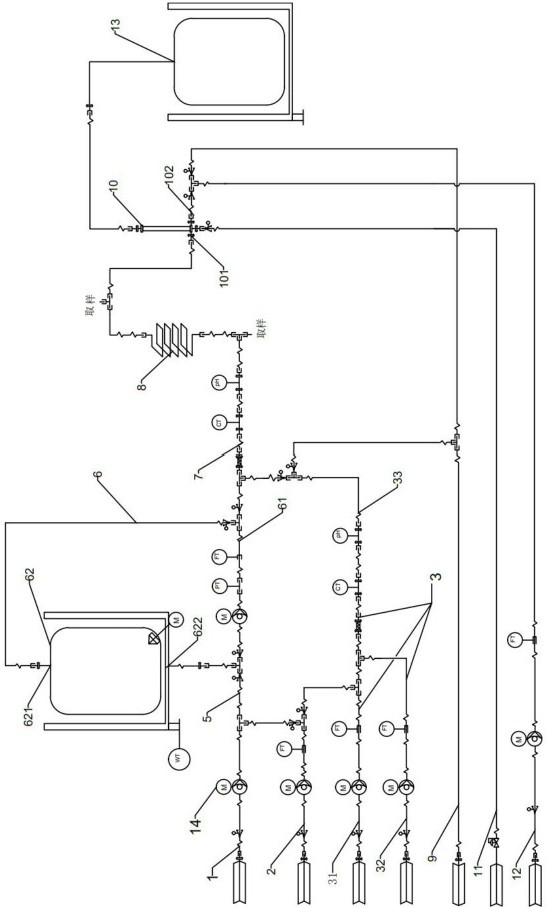

[0031] figure 1 Schematically shows a plasmid DNA alkaline lysis device according to one embodiment of the present invention.

[0032] Such as figure 1 , the plasmid DNA alkaline lysing equipment includes a bacterial liquid pipeline 1, the pipe diameter is preferably 3.2mm, and the bacterial liquid pipeline is provided with a pinch valve and a peristaltic pump 14; the buffer pipeline 2, with a pipe diameter of preferably 6.4mm, is provided with a pinch valve And peristaltic pump 14; Buffer pipeline 2 connects bacterial solution pipeline 1 to mix bacterial solution through T connector or Y connector pipeline, also can directly connect bacterial solution suspension circulating device 6 and mix bacterial solution in circulation pipeline 61, connect The pipeline is provided with a pinch valve; in this embodiment, the mixed bacteria solution pipeline 5 formed after the buffer pipeline 2 is connected to the bacteria solution pipeline 1 is connected to the inlet of the circulation p...

Embodiment 2

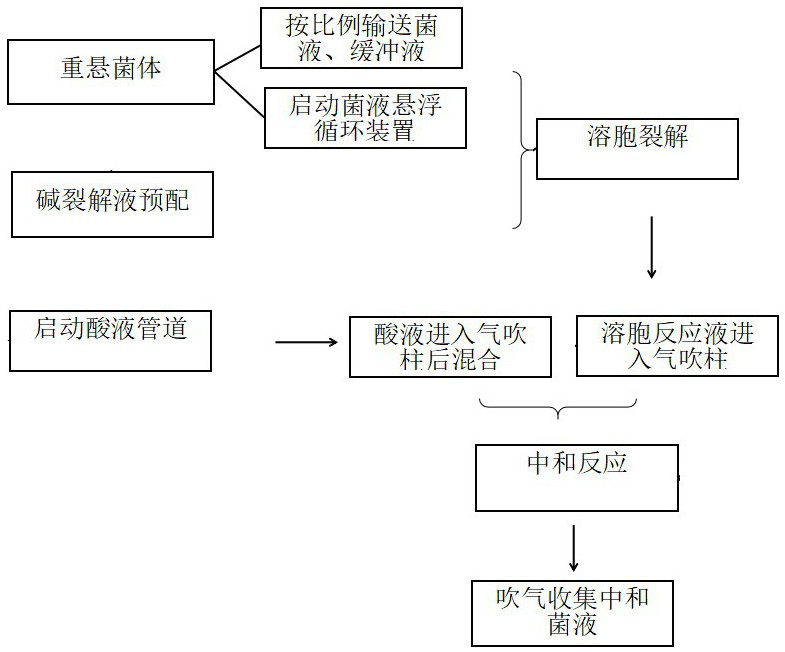

[0042] figure 2 A method for extracting plasmid DNA according to one embodiment of the present invention is schematically shown.

[0043] Such as figure 2 As shown, the method includes the following steps:

[0044] Start the bacteria solution pipeline 1 and the buffer solution pipeline 2, transport the bacteria and buffer solution to the bacteria solution suspension circulation device 6 at a volume ratio of 1:10 through the peristaltic pump 14 and the flow sensor, and close the bacteria solution pipeline 1 after reaching the preset volume and buffer line 2.

[0045] Start the bacterium liquid suspension circulation device 6, and the bacterium mixed liquid circulates in the loop that circulation pipe 61, stirring container 62 constitute; up to the target flow.

[0046] Alkaline lysate is pre-configured: start buffer pipeline 2, lye delivery pipeline 31 and surfactant delivery pipeline 32, alkali lysis solution pipeline 33 communicates with waste discharge pipeline 9, clos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com