Process for preparing aluminum ammonium sulfate by crystallizing two-stage leaching raffinate

A technology of aluminum ammonium sulfate and two-stage leaching, which is applied in the direction of aluminum sulfate, aluminum compounds, aluminum sulfur compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

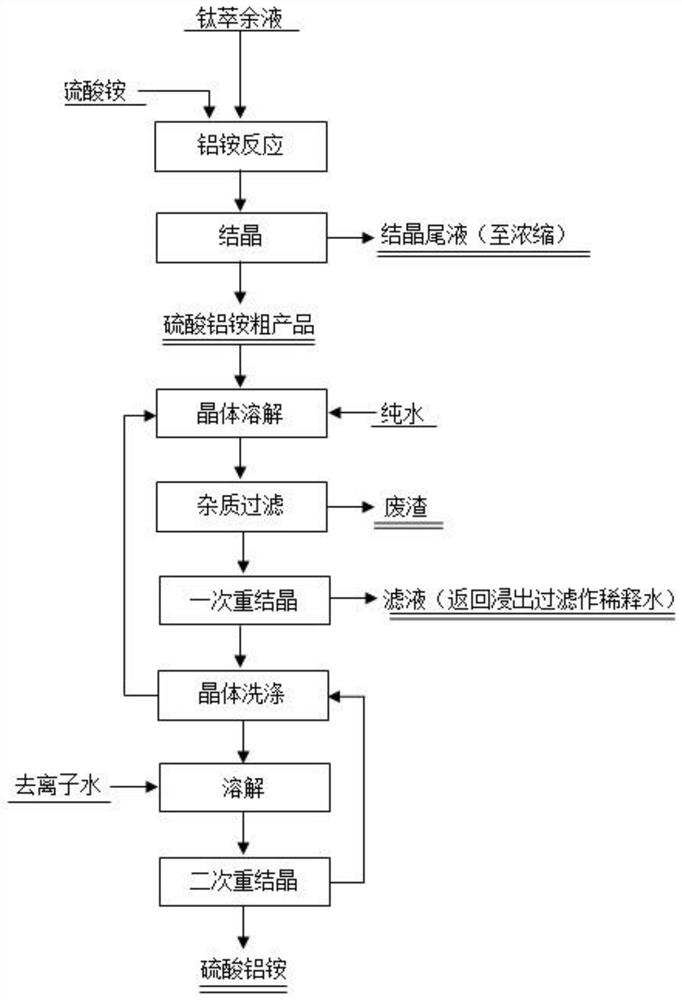

[0057] like figure 1 It can be seen that after titanium is extracted by the second-stage leaching solution, the content of titanium and iron in the solution is low, which is conducive to the preparation of aluminum ammonium sulfate with higher purity. Heat the leaching solution to 80°C, and add (NH 4 ) 2 SO 4 Carry out ammonium-aluminum reaction, maintain the reaction temperature at 80°C, and the reaction time is 30 minutes. After the reaction, feed the liquid into the crystallizer to crystallize aluminum ammonium sulfate, and then filter to obtain the crude product of aluminum ammonium sulfate crystallization. Ammonium Aluminum Sulfate crystallization crude product purification is carried out twice, adopts vacuum crystallization (i.e. a recrystallization) for the first time, the vacuum tightness of control system is 2400Pa, crystallization time is 60min, filters and obtains the thick product of Ammonium Aluminum Sulfate more than 80%, Freeze crystallization (i.e. secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com