Manufacturing method of concrete prefabricated column molding bed

A production method and technology for prefabricated columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of large construction period, damage to fetal membrane, waste of materials, etc., to save site and materials, simple production, short production period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] A method for making a concrete prefabricated column tire mold, carried out according to the following steps:

[0018] A. Make the cushion: first level and compact the production site, and then pour a layer of concrete cushion on the site;

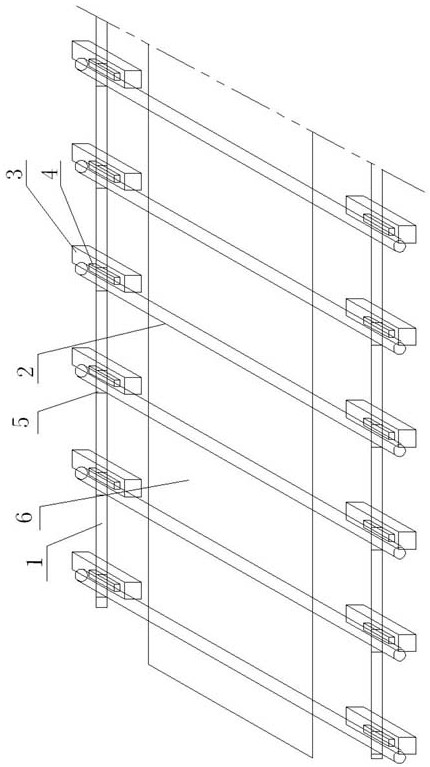

[0019] B. Making the mould: place several long scaffold steel pipes 1 on the cushion along the length direction of the prefabricated column. In this embodiment, two long scaffold steel pipes 1 are arranged, and the top of the long scaffold steel pipe 1 is along the width direction of the prefabricated column Place the short scaffolding steel pipes 2, the short scaffolding steel pipes 2 are equally spaced along the length direction of the prefabricated column, the distance between two adjacent short scaffolding steel pipes 2 is 500mm, the intersection of the short scaffolding steel pipes 2 and the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com