Hydraulic expansion mandrel

A technology of expanding mandrel and hydraulic pressure, applied in the direction of expanding mandrel, gear teeth, gear cutting machine, etc., can solve the problems of difficult maintenance and manufacturing, high cost, complex structure, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical characteristics of the present solution, the present invention will be further elaborated below through specific implementation modes and in conjunction with the accompanying drawings.

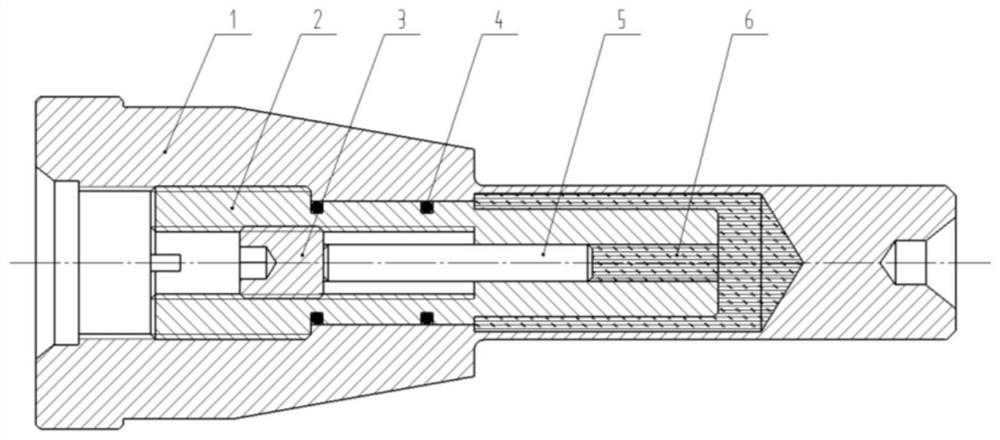

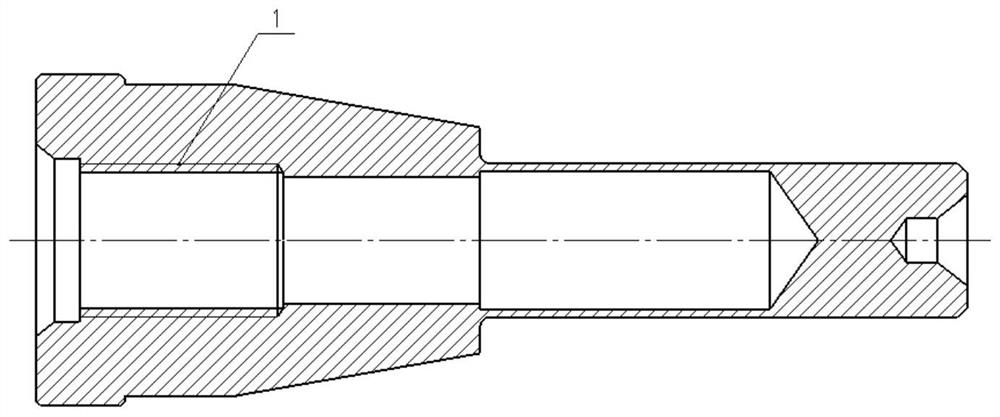

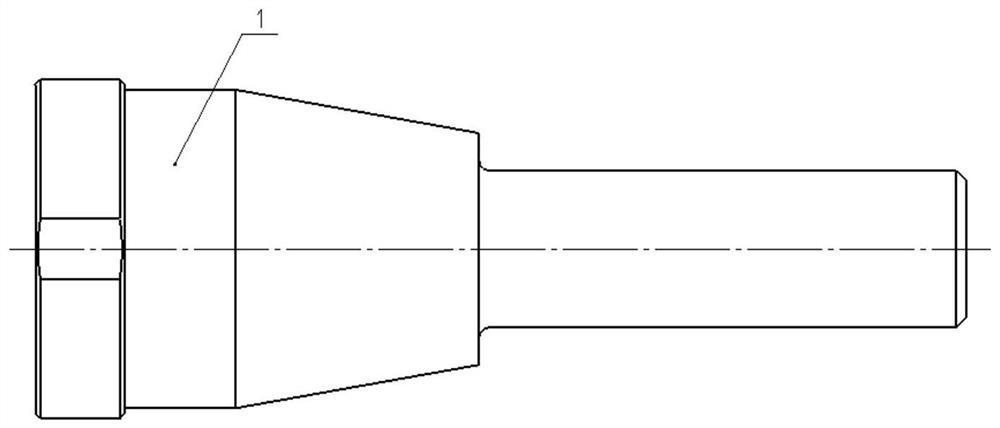

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a hydraulic expansion mandrel includes a shaft body 1, a shaft core 2, a set screw 3, a sealing ring 4, a push rod 5 and hydraulic oil 6, the shaft body 1 is a hollow integral structure, and the left end of the shaft body 1 is provided with Shaft shoulder, two positioning notches are arranged on the outer circumference of the shaft shoulder, the two positioning notches are arranged symmetrically, and the inside of the shaft body 1 is provided with a top hole, a threaded hole, a positioning hole and a thin-walled light hole. The outer circumference of the shaft core 2 is provided with a plurality of circumferential ring grooves, the sealing ring 4 is installed in the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com