Method of preparing humus from kitchen waste

A technology of kitchen waste and humus, applied in the direction of chemical instruments and methods, solid waste removal, recycling technology, etc., can solve the problems of urban waste waste, heavy burden on local finance, and no unified treatment method, etc., and achieve nutrient High, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

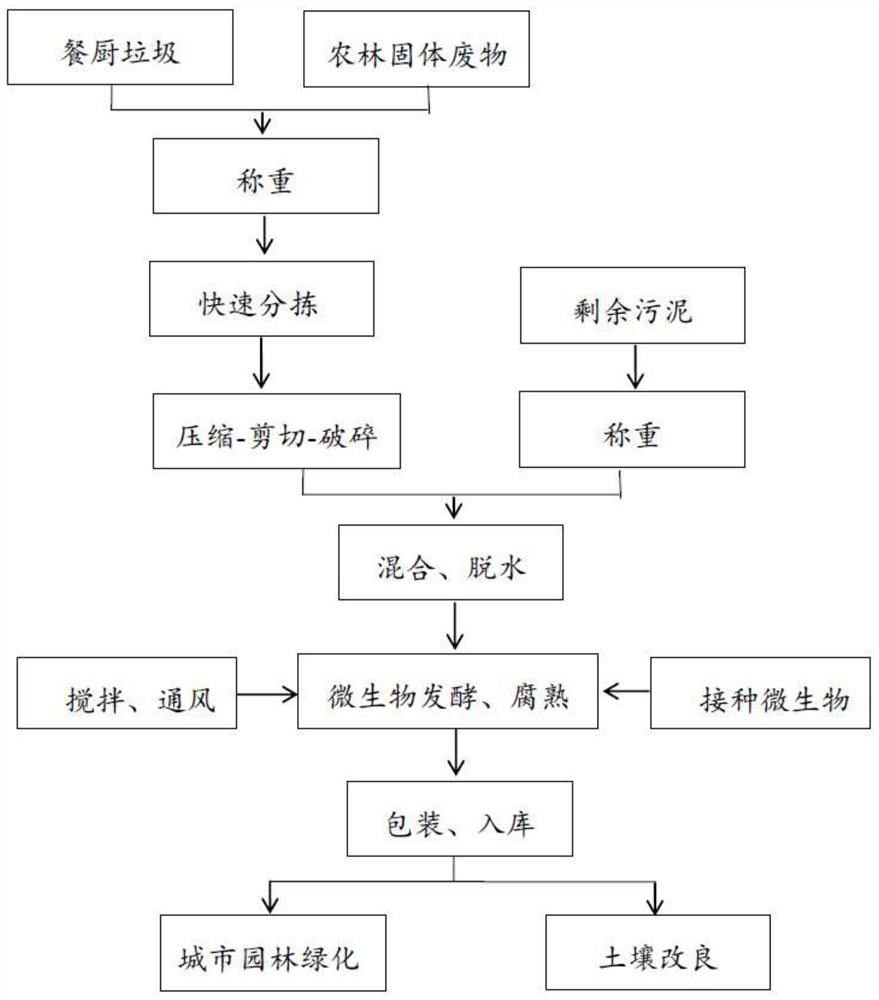

Method used

Image

Examples

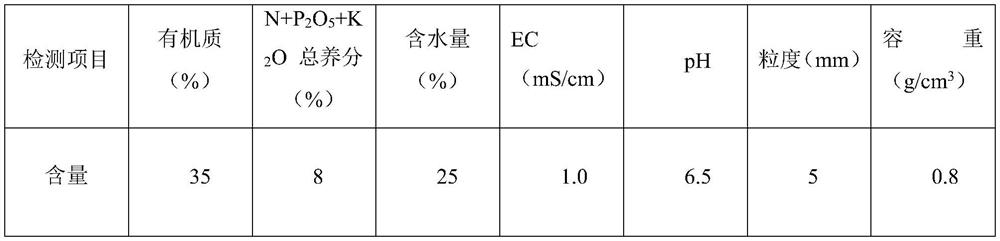

Embodiment 1

[0031] A method for preparing humus from food waste. In terms of mass percentage, the fermentation materials include: 60% food waste, 20% agricultural and forestry solid waste, and 20% residual sludge. The total mass is 1 ton. Put 60% of food waste and 20% of agricultural and forestry solid waste into a 240L standard trash bin, lift and weigh them, and pour them into the sorting device. Through rapid sorting, plastic bags, iron blocks, glass and other impurities are sorted out. The sorted materials are transported to the compression-shearing-crushing device by the chain plate, and are broken into materials with a particle size of 5mm according to the garbage composition and particle size; the crushed material is mixed with 20% of the remaining sludge and transported to the Dehydration device, the moisture content of the mixture after dehydration is 55%, and the liquid is discharged into the liquid storage tank. After the water quality reaches the sewage discharge standard, it e...

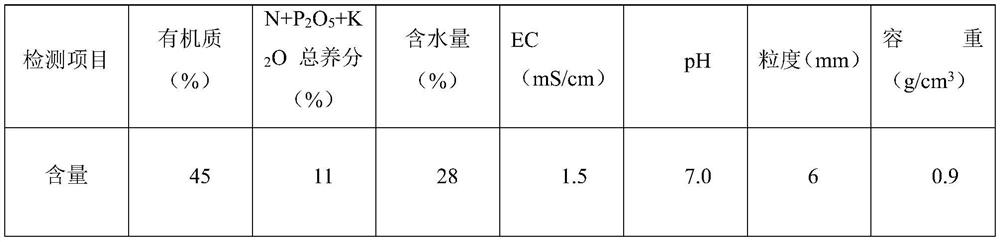

Embodiment 2

[0035]A method for preparing humus from food waste. In terms of mass ratio, the fermentation materials include: 70% food waste, 10% agricultural and forestry solid waste, and 20% residual sludge. The total mass is 5 tons. Put 70% of food waste and 10% of agricultural and forestry solid waste into a 240L standard trash bin, lift and weigh them, and pour them into the sorting device. Through rapid sorting, plastic bags, iron blocks, glass and other impurities are sorted out. The sorted materials are transported to the compression-shearing-crushing device by the chain plate, and are broken into materials with a particle size of 8mm according to the garbage composition and particle size; the crushed material is mixed with 20% of the remaining sludge and transported to the Dehydration device, the moisture content of the mixture after dehydration is 60%, and the liquid is discharged into the liquid storage tank. After the water quality reaches the sewage discharge standard, it enters...

Embodiment 3

[0039] A method for preparing humus from food waste. In terms of mass ratio, the fermentation materials include: 65% food waste, 25% agricultural and forestry solid waste, and 10% residual sludge. The total mass is 3 tons. Put 65% of food waste and 25% of agricultural and forestry solid waste into a 240L standard trash can, lift and weigh them, and pour them into the sorting device. Through rapid sorting, plastic bags, iron blocks, glass and other impurities are sorted out. The sorted materials are transported to the compression-shearing-crushing device by the chain plate, and are broken into materials with a particle size of 8mm according to the garbage composition and particle size; the crushed material is mixed with 10% of the remaining sludge and transported to the Dehydration device, the water content of the mixture after dehydration is 50%, and the liquid is discharged into the liquid storage tank. After the water quality reaches the sewage discharge standard, it enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com