Light guide plate photoetching equipment

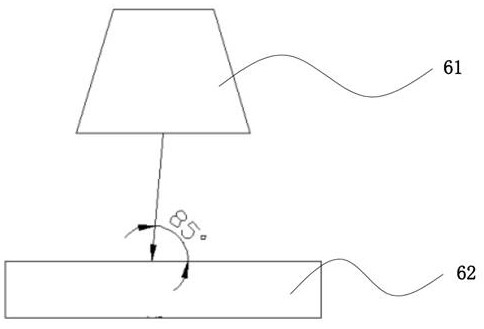

A technology of lithography equipment and light guide plate, applied in microlithography exposure equipment, optomechanical equipment, optics, etc., can solve the problems of non-vertical, eccentric beam, affecting product quality, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

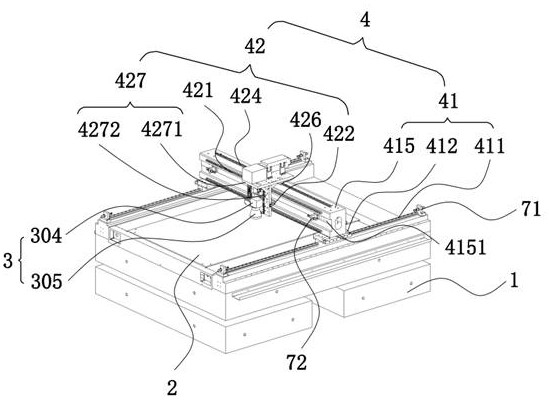

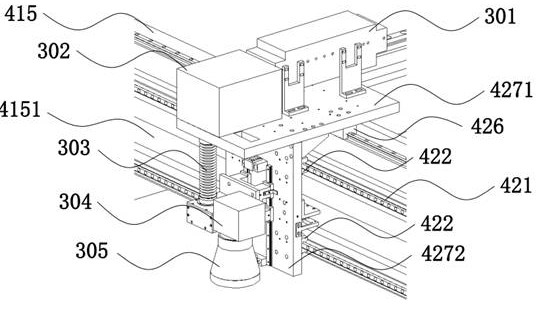

[0021] Please refer to figure 2 and image 3 , the light guide plate lithography apparatus provided in the embodiment of the present invention includes a base 1, a platform 2 arranged on the base 1 for placing the light guide plate and a lithography mechanism 3 for lithography The mechanism 3 moves relative to the platform 2 and the photolithography mechanism 3 uses a guide mechanism 4 for lithography that is always perpendicular to the platform 2 during movement. The guiding mechanism 4 is respectively connected to the photolithography mechanism 3 and the platform 2 . The guiding mechanism 4 includes a first guiding mechanism 41 for realizing the horizontal movement of the lithography mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com