Anchor rod pull-out test device and test method considering temperature and pressure influences

A pull-out test, temperature-pressure technology, applied in measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as long production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

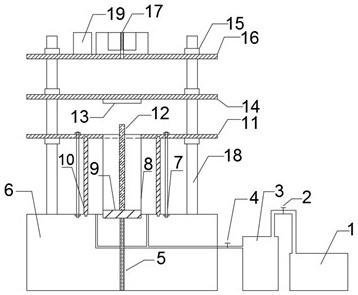

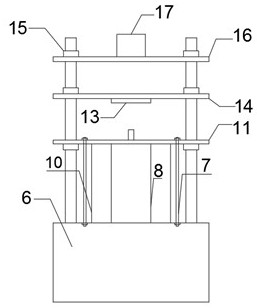

[0051] Such as Figure 1~4 As shown, a bolt pullout test device considering the influence of temperature and pressure includes a base 6, a lower assembly plate 11 is arranged above the base 6, an assembly hole is formed in the lower assembly plate 11, and an assembly hole is set in the assembly hole. There is a workpiece cover 8 for making a test piece or a test piece cover 13 for airtight use. A high-strength glass sleeve 10 is arranged between the base 6 and the lower assembly plate 11. The base 6, the lower assembly plate 11, and the high-strength A closed temperature-controlled and pressure-controlled filling space is formed between the glass sleeve 10 and the test piece cover 13 .

[0052] The upper end of the base 6 and the lower end of the lower assembly plate 11 form an annular groove into which the high-strength glass sleeve 10 can be inserted, and a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com