Integrated biomass gasification low-nitrogen oxygen-deficient combustion boiler

A technology of lean oxygen combustion and biomass, which is applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of low utilization rate of biomass, insufficient combustion, unfavorable environment, etc., and achieve simple installation and high fuel efficiency. Effect of high utilization rate and low environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

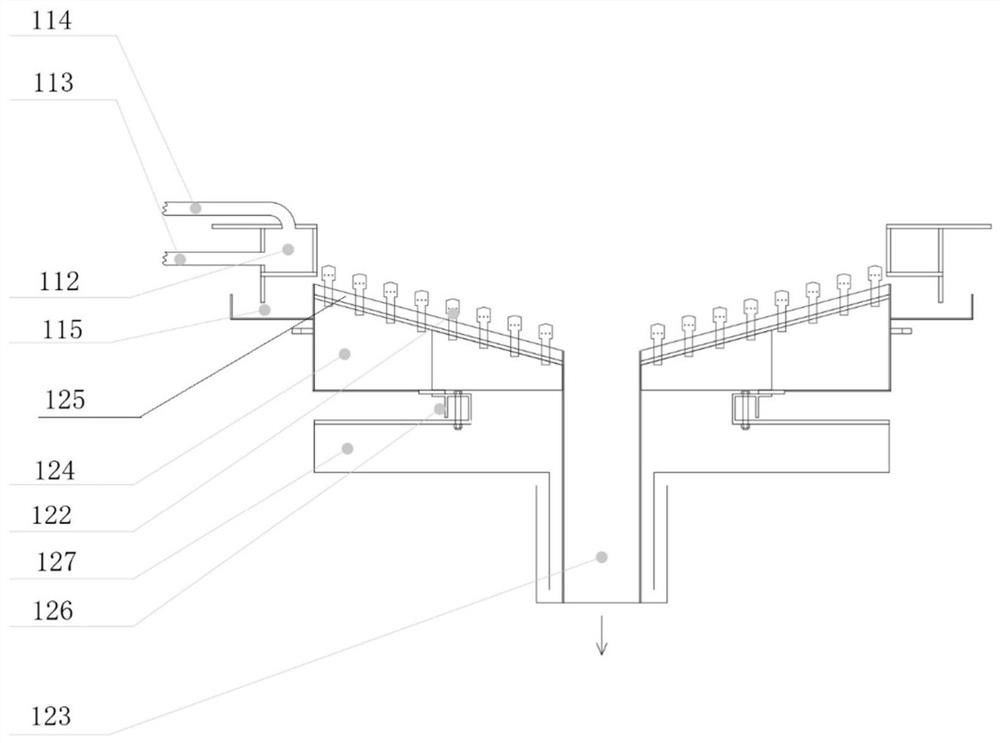

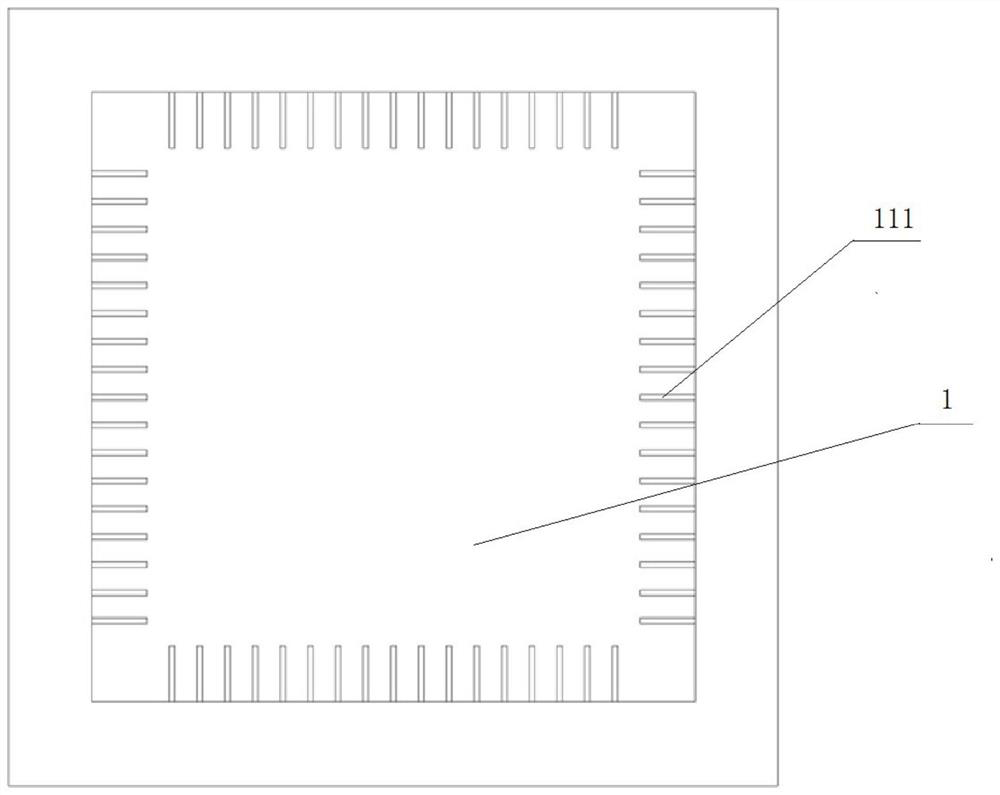

[0037] The integrated biomass gasification low-nitrogen and oxygen-poor combustion boiler includes a gasification gasification combustion zone 1, a heat exchange zone 2, and ash accumulation zone 3 arranged in the same combustion boiler body; the gasification gasification combustion zone 1 includes Gasification combustion chamber 11, rotary gasification combustion bed 12, rotary gasification combustion bed 12 is arranged below gasification gasification combustion zone 1, rotary gasification combustion bed 12 includes: rotary gasification combustion bed 121, bearing 126 Set under the rotary gasification combustion bed 121 and fixedly connected with it, the motor drives the rotary gasification combustion bed 121 to rotate through the bearing 126; the rotary gasification combustion bed 121 is a conical plate, and the wind cap 122 is arranged on the conical plate The central position of the conical plate is hollow, and the hollow position is connected with the ash pipe 123; the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com