Metal graphite symbiotic high-temperature fluid sealing element forming process method

A high-temperature fluid and metal graphite technology, which is used in engine sealing, material forming presses, manufacturing tools, etc., can solve problems such as damage to the original structure of metal materials and decrease in the protective effect of internal graphite sealing, so as to improve the sealing protection performance. , Improve the anti-oxidation ability and high temperature resistance, and prevent the effect of friction and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

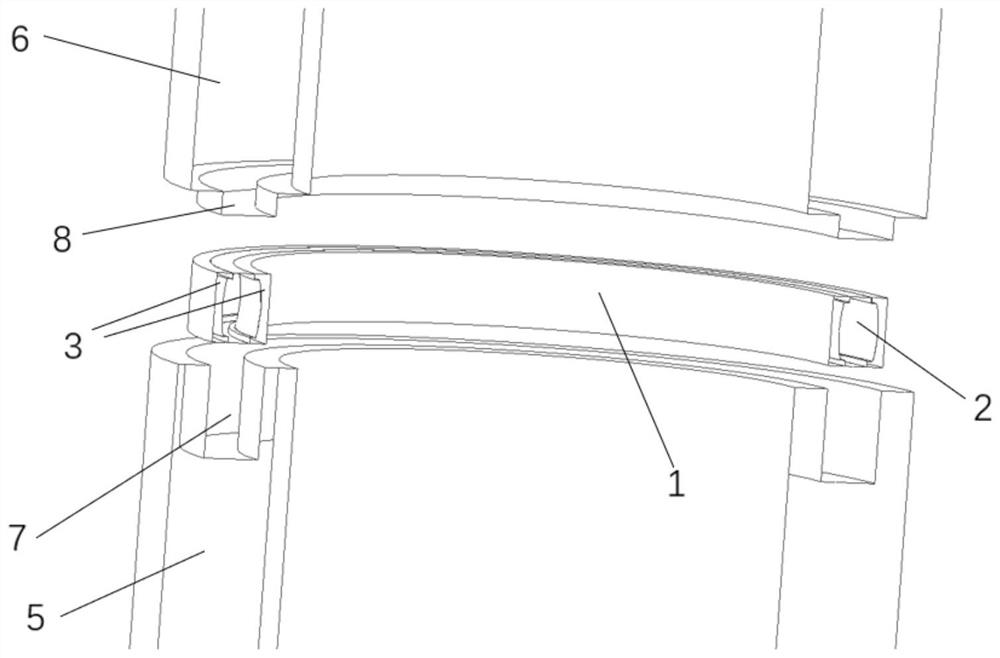

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

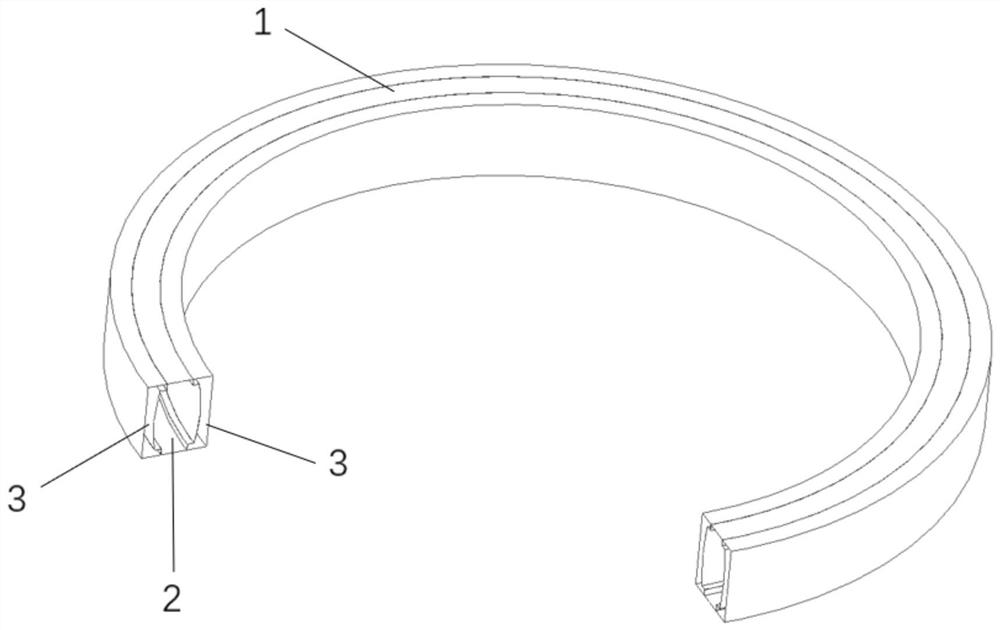

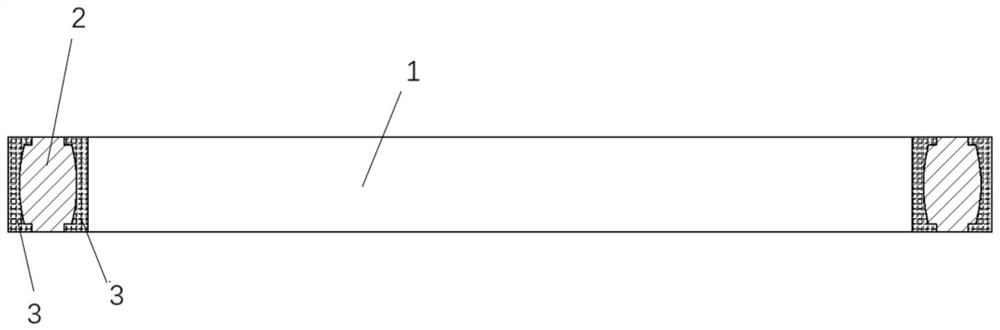

[0024] as attached Figures 1 to 3 In the metal-graphite co-growth high-temperature fluid seal molding process method, an annular and concave molding groove is arranged on the mold under the packing ring, and a mesh metal belt wound into multiple turns is placed in the inner ring and outer ring area of the molding groove , in the middle area of the forming groove, put the graphite tape wound into multiple circles, and make the graphite tape between the mesh metal belts of the inner and outer rings; the lower pressure head of the mold on the packing ring is pressed into the forming groove, and the graphite The packing ring 1 is formed by pressing, and the graphite component of the graphite belt penetrates into the mesh metal belt of the inner ring and the outer ring.

[0025] The compressed graphite packing ring 1 is annular, and the graphite packing ring 1 include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com