Drying and shaping system and drying and shaping process after yarn printing and dyeing

A post-drying and yarn technology, which is applied in the direction of liquid/gas/steam removal by squeeze roller, liquid/gas/steam removal by air jet method, and textile material drum treatment, which can solve the problem of uneven yarn material and economical Loss, unable to dry cloth and other problems, to achieve the effect of improving efficiency and effect, improving effect and efficiency, and reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

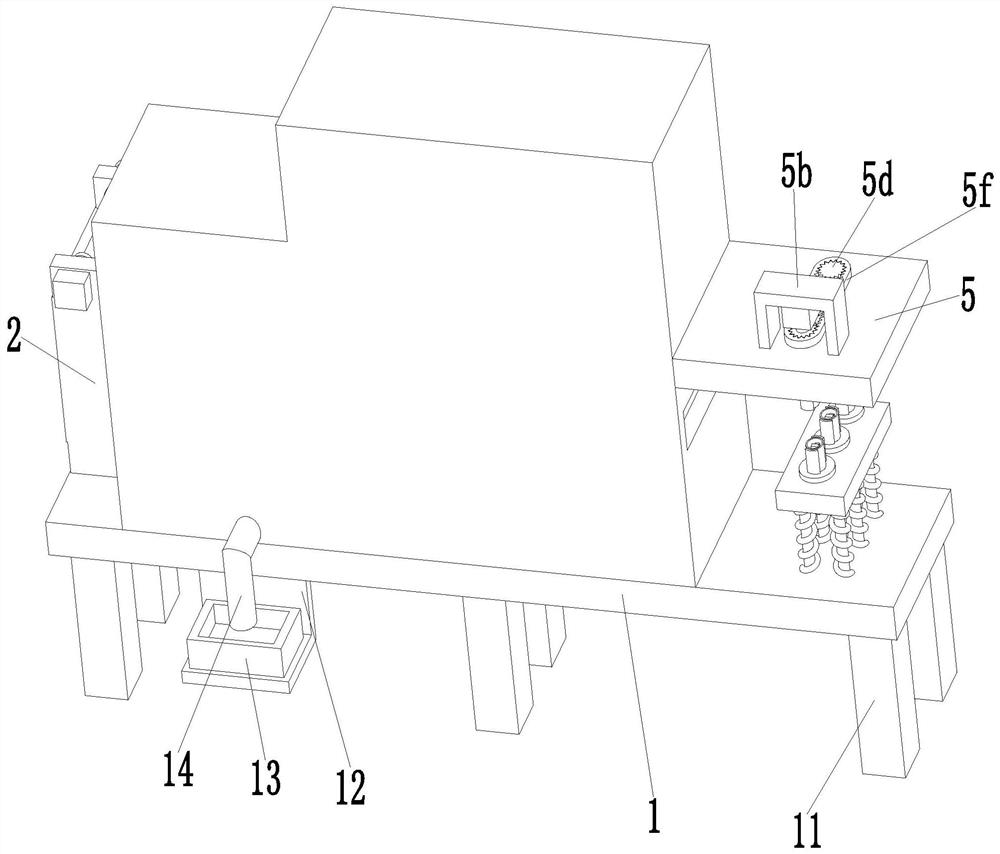

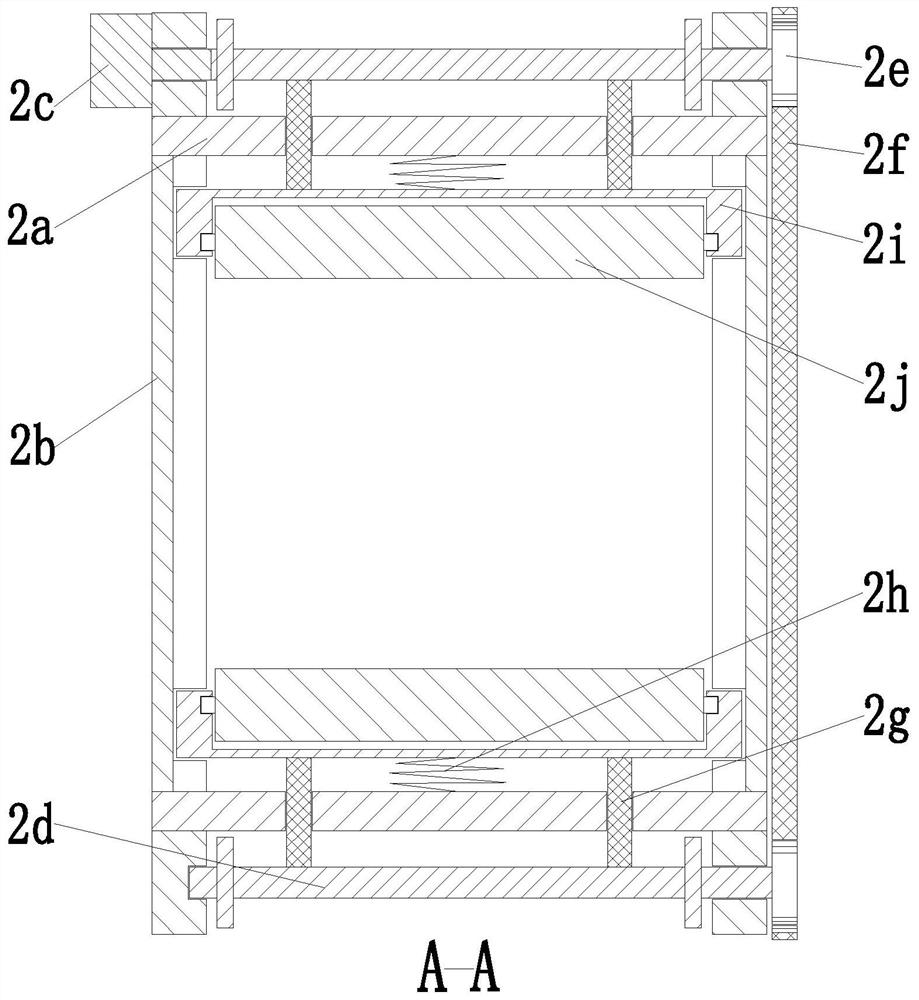

[0030] Such as Figure 1 to Figure 6 As shown, a yarn drying and shaping system after printing and dyeing includes a base plate 1, a thread inlet device 2, a dehydration device 3, a drying device 4, and a thread take-up device 5. The base plate 1 is equipped with a drying device 4, The left end of the drying device 4 is equipped with a wire inlet device 2 , the right end of the drying device 4 is equipped with a take-up device 5 , and a dehydration device 3 is installed in the drying device 4 .

[0031]The take-up device 5 includes a straight plate 5a, a U-shaped plate 5b, a No. 2 motor 5c, a No. 2 gear 5d, a take-up round rod 5e, a synchronous belt 5f, a rotating circular plate 5g, a clamping plate 5h, and a take-up spring bar 5i , T-shaped round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com