Circulating filtration and sedimentation equipment for water treatment

A circulating filtration and water treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of clean impurities in water, power consumption, etc., and achieve good treatment The effect of accelerating the binding speed and improving the efficiency of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

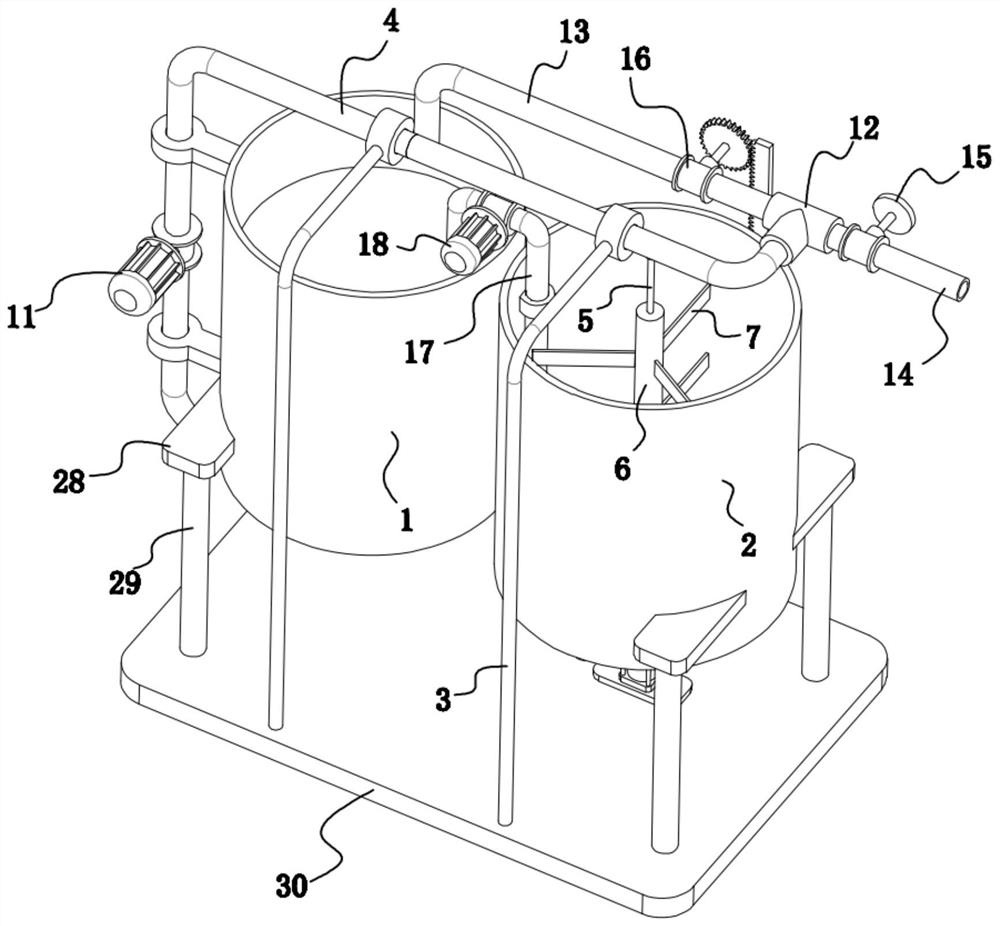

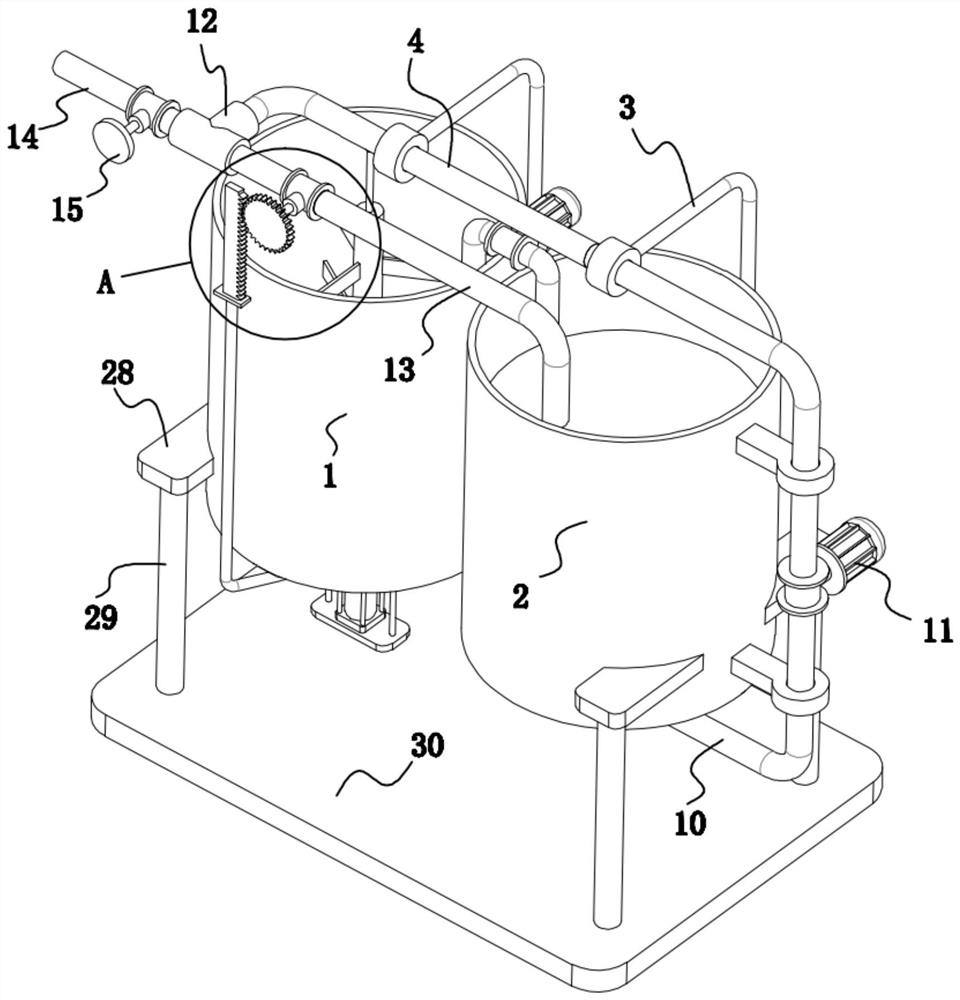

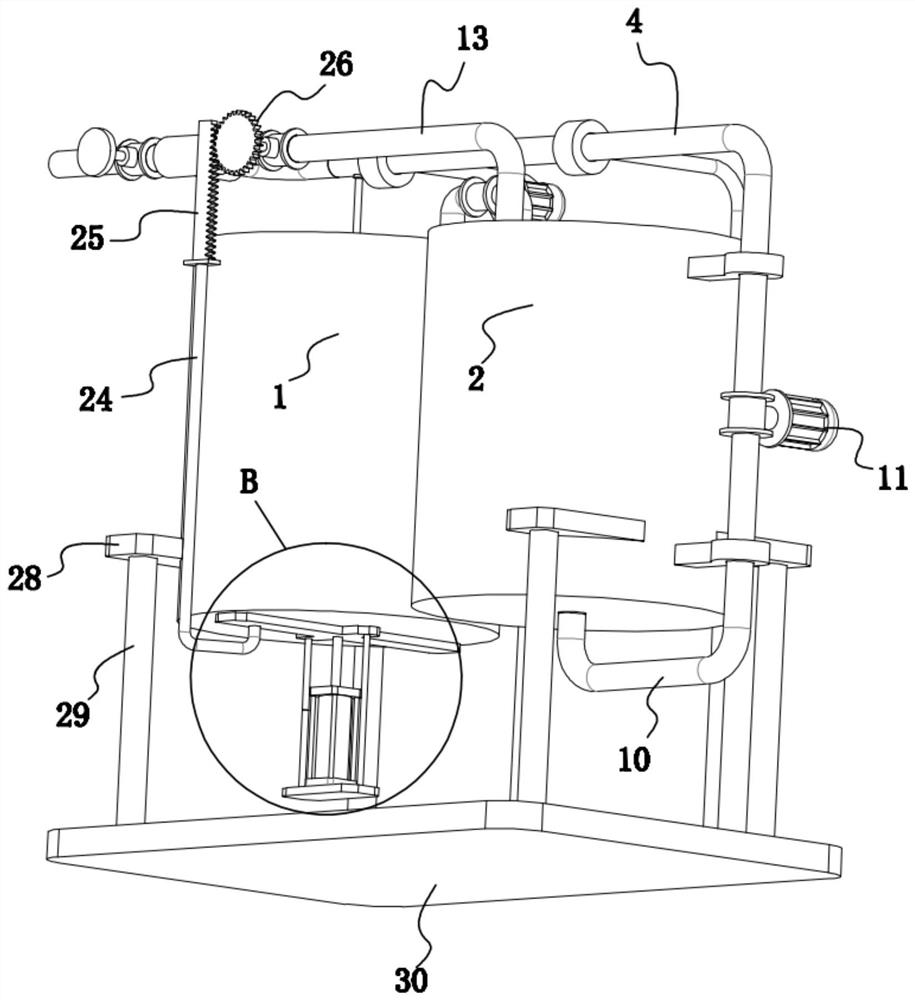

[0023] refer to Figure 1-8 , a kind of circulating filtration sedimentation equipment for water treatment, comprising corresponding settling bucket 1 and filter bucket 2, the outer surfaces of sedimentation bucket 1 and filter bucket 2 are fixed with several fixed blocks 28, and the lower surface of each fixed block 28 is A support leg 29 is fixedly installed, and the bottom ends of the support leg 29 are all fixedly connected on the same workbench 30 .

[0024] The upper surface of the workbench 30 is fixedly equipped with several supporting frames 3 correspondingly arranged, and the first connecting pipe 4 located directly above the sedimentation bucket 1 and the filter bucket 2 is fixedly installed between the supporting frames 3, and the lower pipe of the first connecting pipe 4 The wall is rotatably mounted with a rotating shaft 5 coaxial with the settling barrel 1, the top of the rotating shaft 5 extends upwards into the first connecting pipe 4, and the top of the rotat...

Embodiment 2

[0028] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the flow diversion mechanism includes a tee 12, a third connecting pipe 13, a fourth connecting pipe 14, a first valve 15, a second valve 16, the first The other end of the connecting pipe 4 is fixedly installed with a tee 12, and the remaining two interfaces of the tee 12 are respectively inserted with a third connecting pipe 13 and a fourth connecting pipe 14, and the outer end of the third connecting pipe 13 is inserted into the filter cartridge 2, A second valve 16 is installed on the third connecting pipe 13 , and a first valve 15 is installed on the fourth connecting pipe 14 . Both the first valve 15 and the second valve 16 are ball valves, and the closing and opening of the valves are controlled by rotating the valves.

[0029] In this embodiment, since the tee 12 is provided, the water flow in the first connecting pipe 4 can be diverted to the...

Embodiment 3

[0031] refer to Figure 4-8 , as another preferred embodiment of the present invention, the difference from Embodiment 2 is that a scraper 8 is fixedly installed at the bottom end of the stirring shaft 6, the lower surface of the scraper 8 is in contact with the bottom surface of the settling bucket 1, and the inner bottom of the settling bucket 1 There is a through groove on the surface, and an insert block 19 is inserted in the through groove. After the bottom end of the insert block 19 extends downwards out of the through groove, a baffle plate 20 is fixedly installed. Two guide rods 21 are arranged on the baffle plate 20. 21 tops are all fixedly connected on the bottom surface of the sedimentation bucket 1, a base plate 22 is fixedly installed between the bottom ends of the two guide rods 21, and a cylinder 23 is fixedly installed on the upper surface of the base plate 22, and the end of the output shaft of the cylinder 23 is fixedly connected to the baffle plate 20 Above,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com