Sanitary ceramic slip casting line

An assembly line and grouting technology, which is applied to ceramic molding machines, ceramic molding workshops, die-casting molds, etc., can solve the problems of large space occupation, low blanking efficiency, and high labor intensity of workers, so as to achieve small site occupation and high efficiency. Work efficiency, the effect of breaking down the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

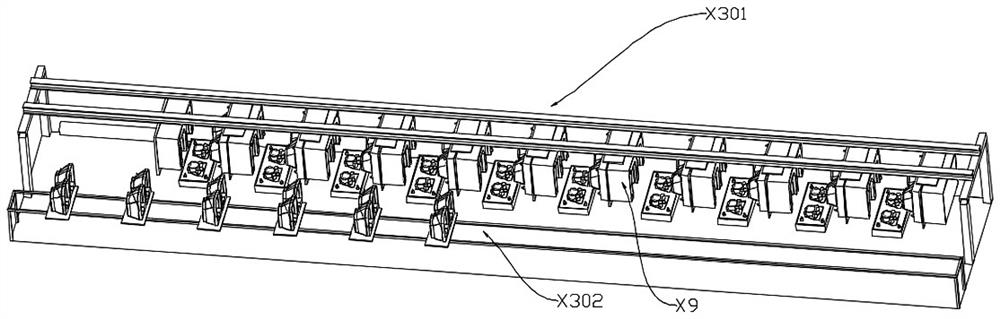

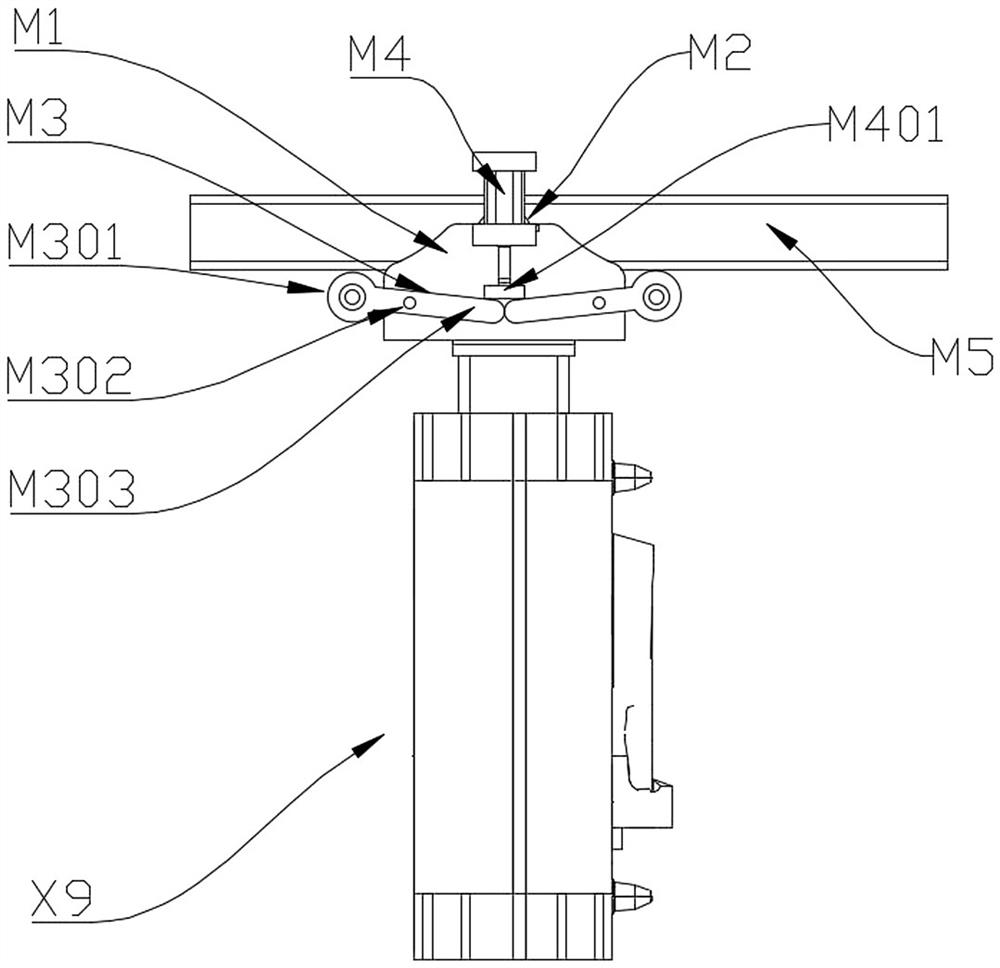

[0032] Specific implementation method: combined Figure 1-2 As shown, a ceramic toilet grouting production line mainly includes a seat ring grouting production line X1, a liner and jacket grouting production line X2, a grouting line X5 and a bonding line X6. The seat ring grouting production line X1 mainly includes: Seat ring high-pressure grouting machine X101 and seat ring transmission line X102, the seat ring transmission line X102 is arranged on one side of the seat ring high-pressure grouting machine X101 in parallel, between the seat ring transmission line X102 and the seat ring high-pressure grouting machine X101 An automatic billet removal car X103 is provided, which can move the seat ring blank formed in the seat ring high-pressure grouting machine X101 to the seat ring transmission line X102. The liner and jacket grouting production line X2 mainly includes: a liner high-pressure grouting machine X201 and a jacket high-pressure grouting machine X301 arranged in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com