Sliding block type pipe expanding die

A slide type, tube die technology, applied in the field of tube expansion die, can solve the problems of troublesome device adjustment, low efficiency, cumbersome and other problems, and achieve the effect of reducing hidden safety hazards, reducing personnel costs, and reducing inefficiency problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Example: such as Figure 1-5 As shown, a slider-type pipe expansion die of the present invention includes a base 1, a tool box 12 is fixedly installed in the middle of the front of the base 1, an abutment 101 is provided at the bottom of the base 1, and a main body 2 is provided at the top of the base 1;

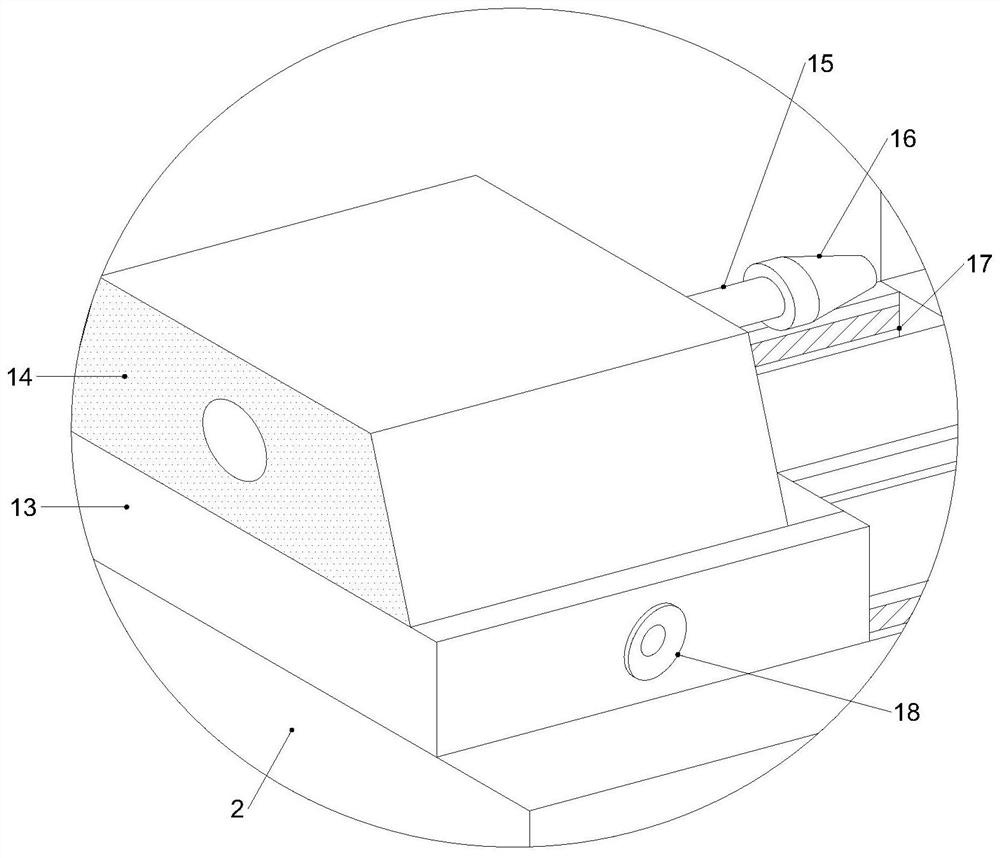

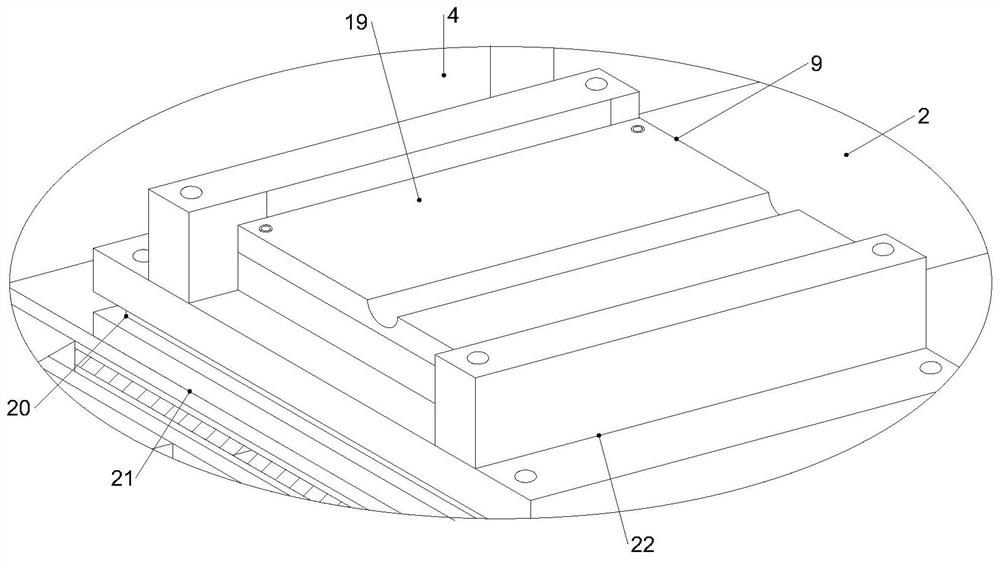

[0027] The main body 2, the top of the main body 2 is inlaid with the first chute 17 and the second chute 24, and the top surface of the main body 2 is fixedly installed with the extrusion device 3, the lower mold 9 and the distance adjustment device 8 in sequence from one side to the other side , the bottom of the extrusion device 3 is provided with an extrusion machine base 13 and an adjustment handwheel 18, and the top of the extrusion device 3 is provided with a double-stroke oil cylinder 14, a telescopic extrusion rod 15 and a pipe expansion head 16, and the lower mold 9 includes a fixed The base 21, the telescopic backing plate 20 and the formwork 19, the two si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com