Automatic cleaning device for garbage can

An automatic cleaning and trash can technology, applied in the field of trash can cleaning, can solve the problems of inability to perform cleaning treatment well, the cleaning effect is not satisfactory, and cannot guarantee complete flushing, etc., and achieves clean, thorough and efficient cleaning and disinfection work. In-line cleaning, low labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

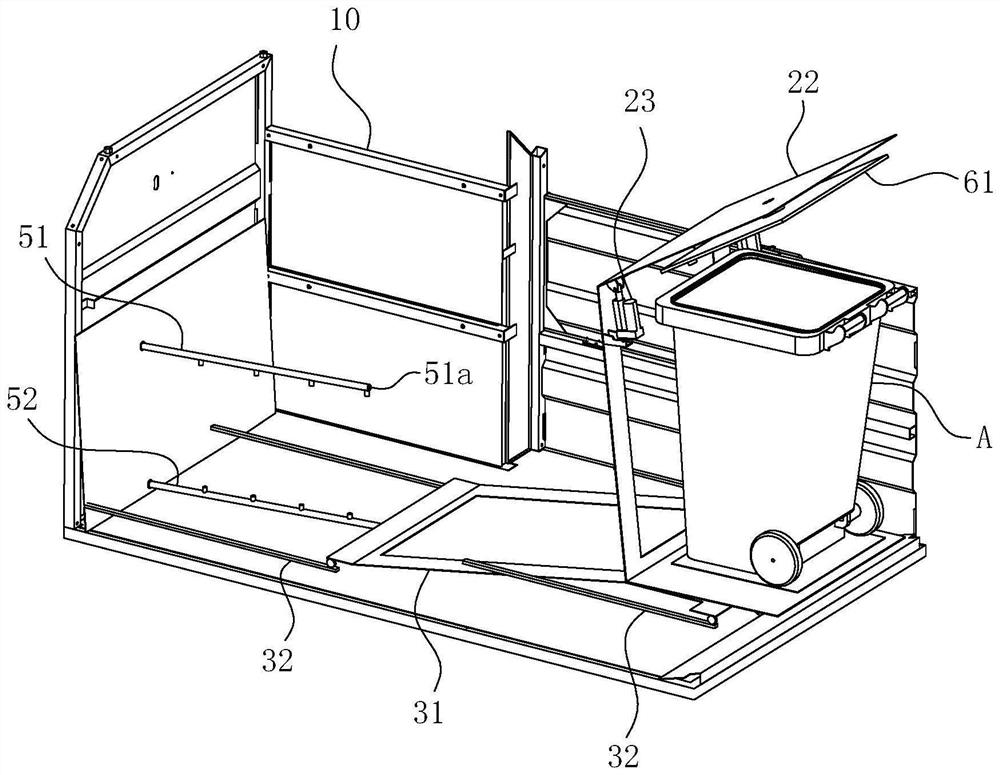

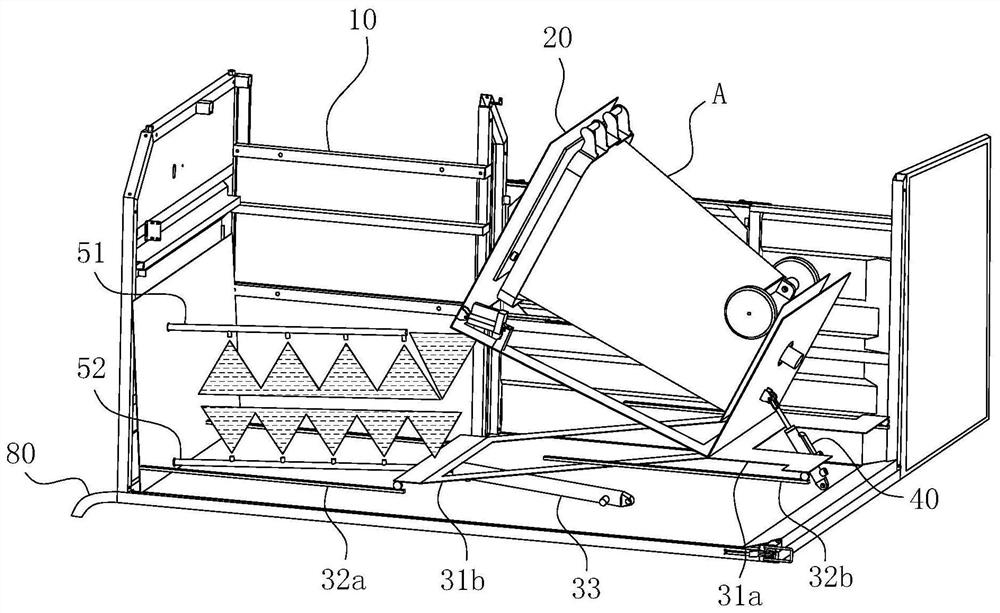

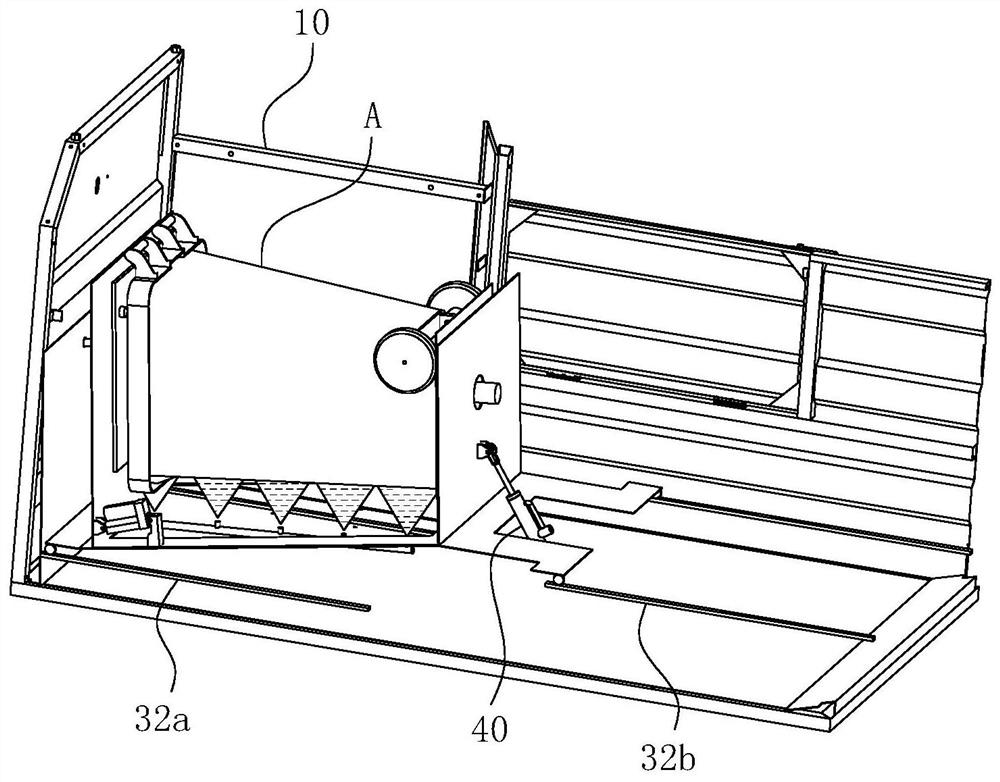

[0040] The concrete implementation structure of the present invention can refer to Figure 1-4 As shown, its main structure includes a box body 10, inside the box body 10 such as figure 1 Shown is divided into access area and cleaning area. In actual use, the present invention can use electric energy to work, and the energy consumed is completely provided by the energy system, and other mechanisms are all attached to the box body 10 . The casing 10 is welded by high-quality stainless steel, and a cleaning door is set at the access position of the trash can A, so that a closed space can be formed independently when cleaning. in:

[0041] In the access area, an overturn bracket 20, a translation platform 31 and a translation guide rail 32 are arranged. The translation guide rail 32 is installed in the casing 10, and rollers or sliders are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com