Vacuum cup and processing method thereof

A thermos cup and cup bottom technology, applied in the field of heat preservation, can solve the problems of easy occurrence of non-vacuum, high processing difficulty and high cost, and achieve the effects of improving product qualification rate, high product consistency and low processing cost.

Inactive Publication Date: 2020-09-29

蒋文柏

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Although the above-mentioned thermos cup has the above advantages, there are certain defects. The vacuum of the thermos cup generally needs to be in a high-temperature environment, which is about 400°C. The melting point of titanium and steel is different, so it is difficult to be effective. Welding, and it is difficult to achieve seamless welding, the vacuum degree is affected, resulting in gas trapped between titanium and steel, at high temperature, the gas expands and causes the extrusion deformation of the titanium liner

[0006] Secondly, the use of stainless steel titanium rings for sealing welding is costly and poor in drop resistance, and is prone to non-vacuum phenomena. At the same time, this process is very difficult to process, because the stainless steel titanium rings need to be welded after vacuuming. Affect the degree of vacuum, and it is not easy to be popularized and applied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

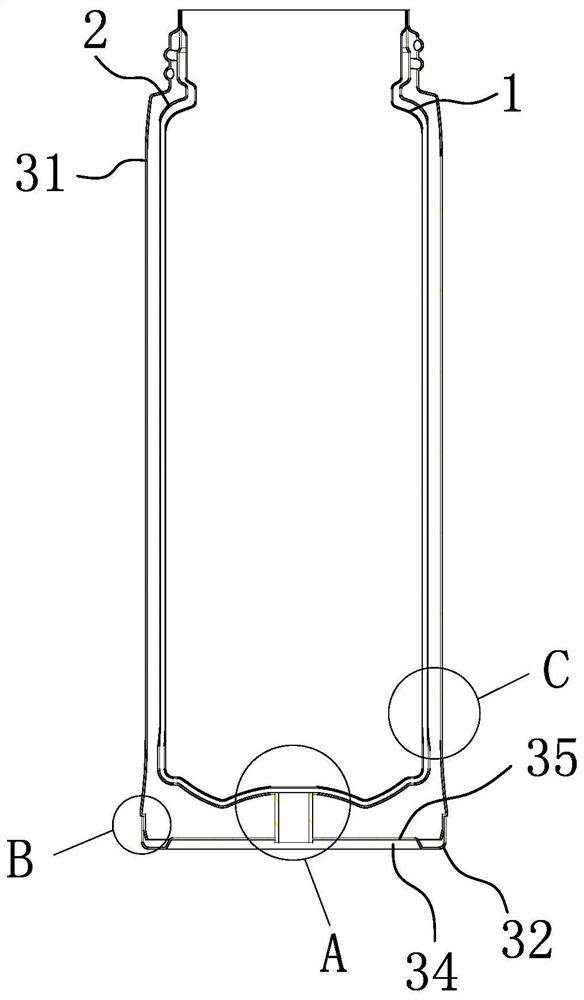

[0065] The working principle of this embodiment is basically the same as that of Embodiment 1, the only difference is that one end of the pressure tube 4 is inserted into the upper insertion hole 21 and the pressure tube 4 and the upper insertion hole 21 are fixed together with an adhesive material. Bonding materials include glass beads and the like.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of heat preservation, and particularly relates to a vacuum cup and a processing method thereof. The technical problem that an existing titanium vacuum cupis not easy to machine and manufacture is solved. The vacuum cup comprises a titanium layer, a middle stainless steel layer and an outer stainless steel layer which are sequentially arranged from inside to outside, the vacuum cup is characterized in that the upper end of the titanium layer is welded with the upper end of the middle stainless steel layer; a closed space is formed between the titanium layer and the middle stainless steel layer; the upper end of the middle stainless steel layer and the upper end of the outer stainless steel layer are connected in a welded mode, a vacuum cavity isformed between the middle stainless steel layer and the outer stainless steel layer through vacuumizing, and a pressure pipe penetrating through the vacuum cavity and enabling the closed space to becommunicated with the outside is connected between the bottom of the middle stainless steel layer and the bottom of the outer stainless steel layer. The processing method has the advantage that the production and processing efficiency is improved.

Description

technical field [0001] The invention belongs to the technical field of heat preservation, and in particular relates to a heat preservation cup and a processing method thereof. Background technique [0002] Thermos cups made of titanium liner materials are widely used. [0003] The structure of the thermos cup with titanium liner is: titanium liner, middle stainless steel and outer stainless steel, vacuum is drawn between the titanium liner and the middle stainless steel, and vacuum is drawn between the middle stainless steel and the outer stainless steel, using vacuum to achieve ideal heat preservation Effect. [0004] For example, a Chinese patent discloses a three-layer vacuum titanium cup and its preparation process, application number 201910608824.X, which includes a titanium liner, a stainless steel middle layer, and a stainless steel outer layer at intervals from the inside to the outside. The top of the stainless steel middle layer and the stainless steel outer laye...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47G19/22B23K31/02B23K37/00

CPCA47G19/2288B23K37/00B23K31/02

Inventor 蒋文柏

Owner 蒋文柏

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com