Electric automated quick ridge making and compressing device

A technology of electric automation and compaction device, which is applied in the direction of adjustment device, lifting device of agricultural machinery, shovel, etc. It can solve the problems of height adjustment ridge-making mechanism deformation, ridge surface collapse, ridge soil density and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

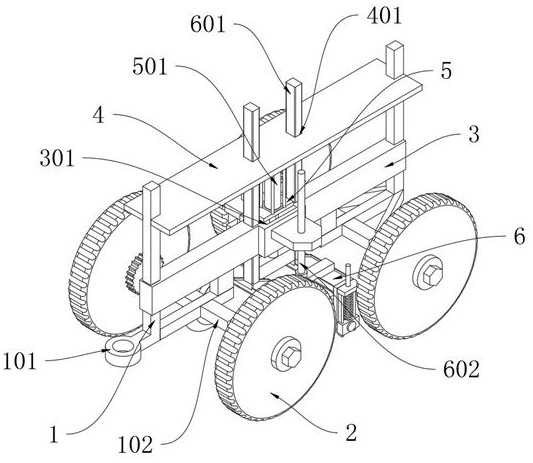

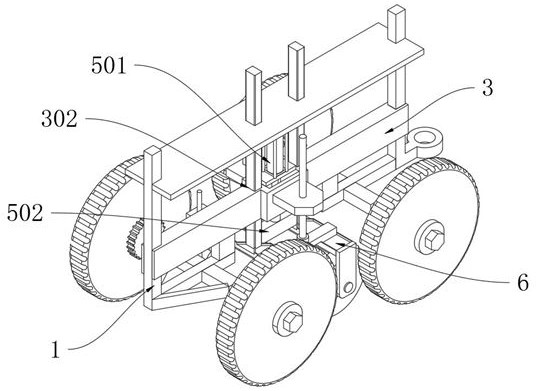

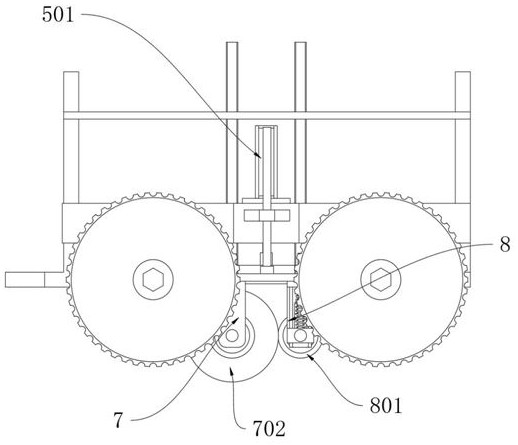

[0033] as attached figure 1 to attach Figure 9 Shown:

[0034]The present invention provides an electric automatic rapid ridge forming and compacting device, which comprises a vehicle frame body 1; the front bottom and the rear end bottom of the vehicle frame body 1 are installed with two wheels 2 through the rotation of roller shafts; the vehicle frame body 1 includes a traction ring 101 and axle frame 102, the middle part of the front end of the frame body 1 is fixedly extended forward to be provided with a horizontal traction ring 101, and the bottom of the front end and the bottom of the rear end of the frame body 1 are respectively fixed and downwardly installed with a downwardly convex re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com