Electrical automation equipment maintenance protection device

A technology for electrical automation and equipment maintenance, which is applied to electrical equipment shells/cabinets/drawers, electrical components, and modification using gaseous coolants, etc. It can solve the problem of not having any warning structure, not setting the placement position of parts, and losing the buffer of the spring Effect and other issues, to achieve the effect of improving the protection effect, avoiding the loss of parts, and effectively buffering the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

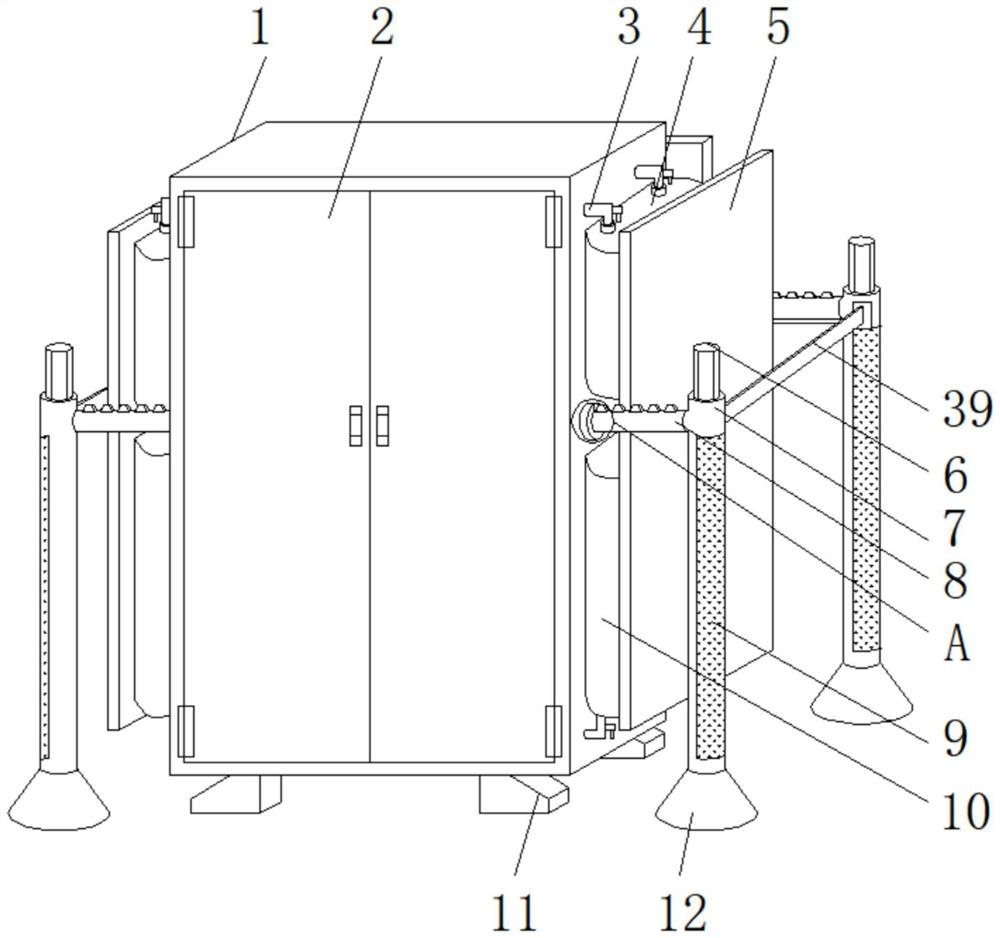

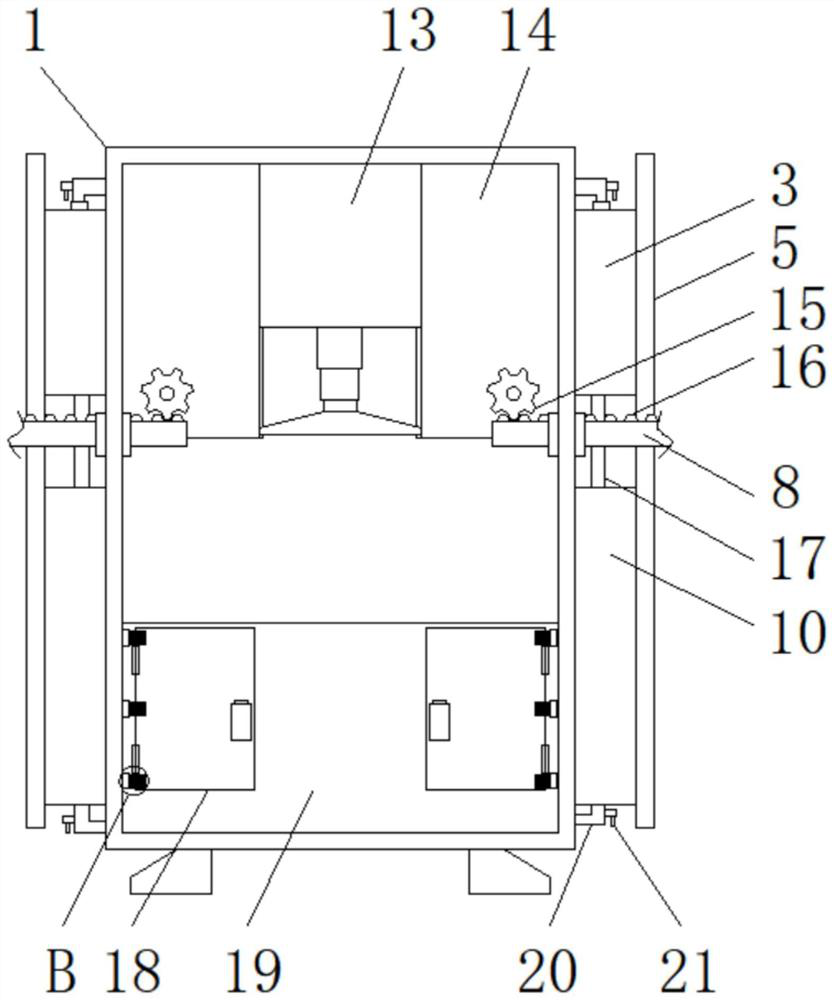

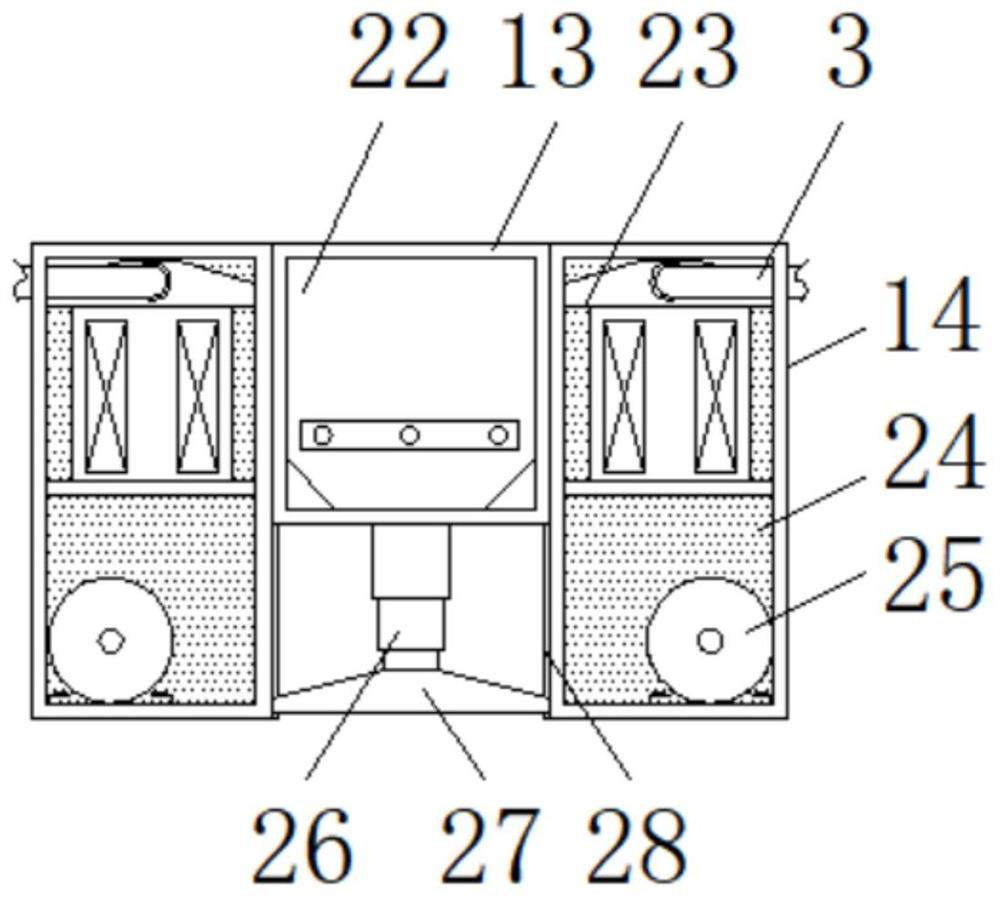

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0031] Such as Figure 1-8 As shown, the embodiment provides a maintenance protection device for electrical automation equipment, including a casing 1, a first protective airbag 4, a protective outer panel 5 and a second protective airbag 10, and the inner wall of the top surface of the casing 1 is fixed A first installation inner shell 13 and a second installation inner shell 14 are installed, an electric air pump 23 and a drive motor 25 are fixedly installed inside the second installation inner shell 14, and an inflator is fixedly installed on the output end of the electric air pump 23. Tube 3, the first protective airbag 4 and the second protective airbag 10 are fixedly installed on one side of the outer wall of the casing 1, and one end of the inflation tube 3 passes through and extends to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com