A kind of Lunebo lens and the production method of the Lunebo lens

A technology of Lunberg lens and production method, which is applied to antennas, electrical components, etc., can solve the problems of difficult to produce products, cumbersome production process, easy contact of metal fibers, etc., and achieve the effects of simple production process, reasonable design and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

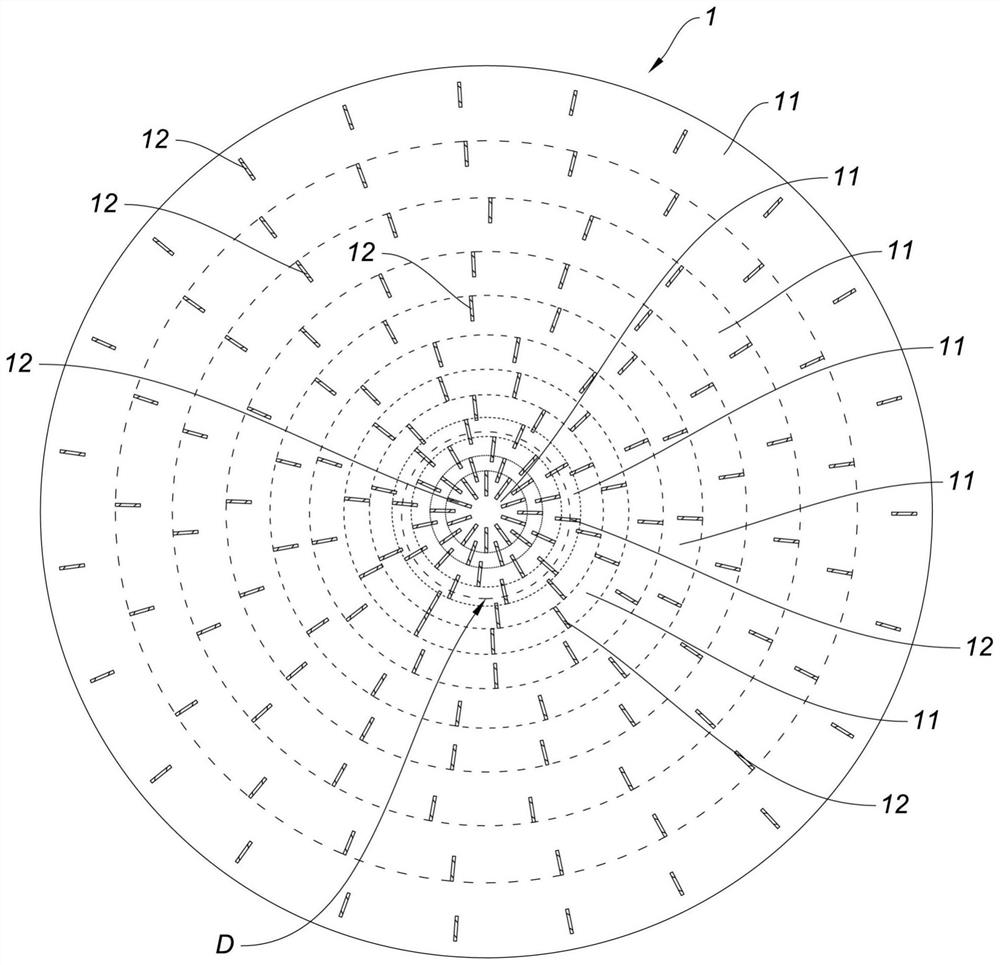

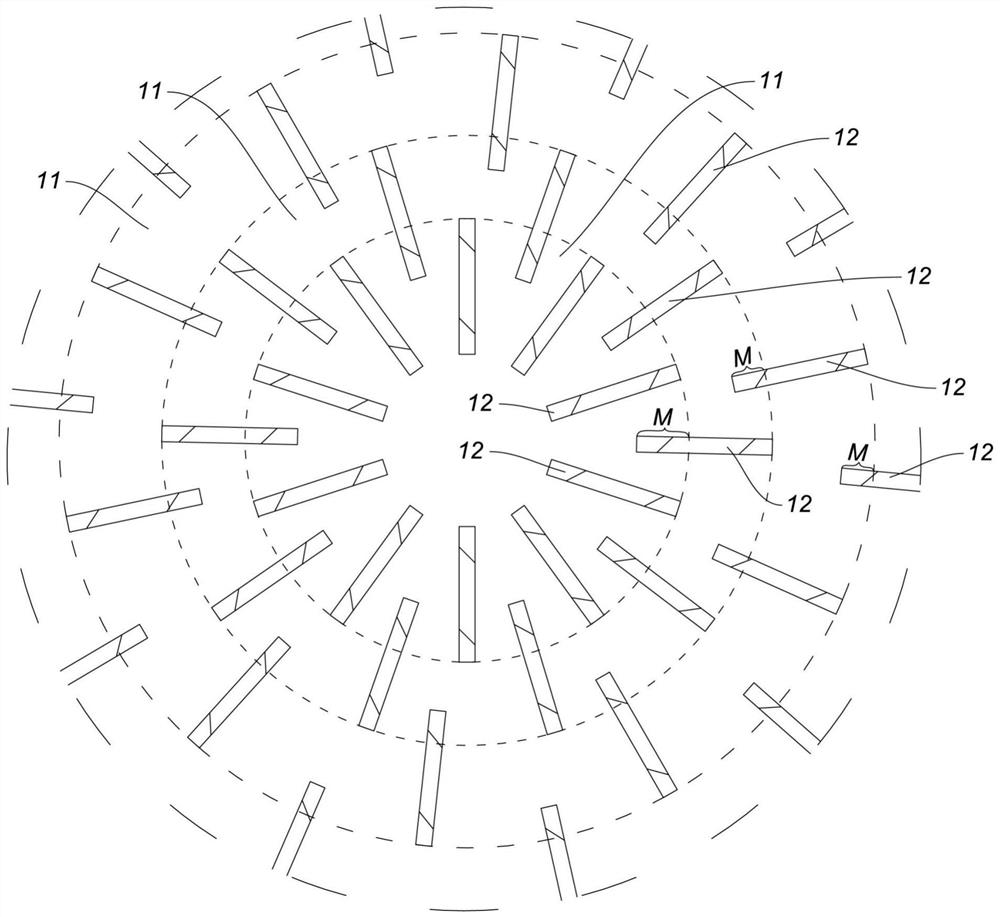

[0036] Such as figure 1 , figure 2 , image 3 As shown, the present embodiment is a Lunberg lens, including a main body 1, the main body 1 is made of insulating material, an electromagnetic wave incident area is formed on the outer surface of the main body 1, and an electromagnetic wave incident area is formed from the center of the main body 1 to the electromagnetic wave incident area. Several layers of conductive material layers 11 are arranged in sequence, and each conductive material layer 11 includes a plurality of conductive wires 12 evenly inserted and embedded in the body 1; the conductive wires 12 in each layer of conductive material layer 11 are conductive wires of the same length , between two adjacent conductive wires 12 in each conductive material layer 11 are blocked by the insulating material constituting the body 1; between two adjacent conductive material layers 11: the conductive wire of one layer of conductive material layer 11 12 and the conductive threa...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is: as Figure 4 , Figure 5 As shown, the body 2 is a cylindrical structure, the center of the body 2 is its axis a, the side of the body 2 is the electromagnetic wave injection area, and the conductive wires 22 of each conductive material layer 21 are all directed to the axis a of the body 2 . In this embodiment, the main body 2 is designed as a cylindrical structure to meet the needs of customers for different application scenarios.

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 is: as Image 6 , Figure 7 As shown, the body 3 is an ellipsoid structure, the center of the body 3 is its major axis b, the outer surface between the two focal points on the body 3 is the electromagnetic wave injection area, and the two focal points on the body 3 are points F1 and At point F2 , the conductive filaments 32 of each conductive material layer 31 are directed to the long axis b of the body 3 . In this embodiment, the main body 3 is designed as an ellipsoid structure to meet the needs of customers for different application scenarios.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com