Multi-working-condition simulation combination device for foundation pile low strain detection

A combined device and low-strain technology, applied in the field of low-strain detection, can solve the problems of limited types and locations of concrete simulated pile defects, difficulty in cultivating the comprehensive analysis level of inspectors, and failure to achieve the theoretical analysis level of actual measured defects. The effect of small land area, good implementation effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

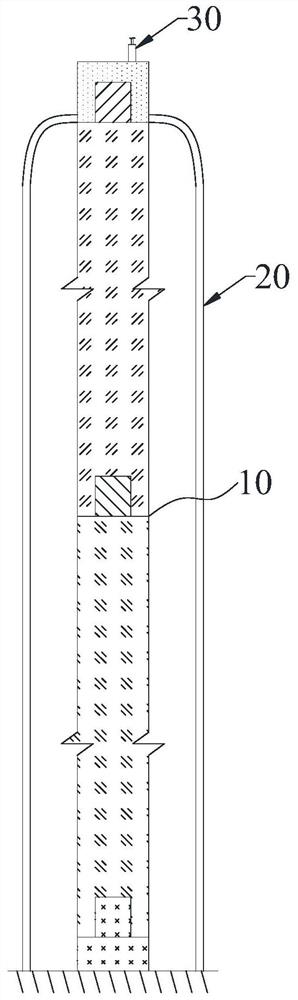

[0054] like figure 1 As shown, the multi-working-condition simulation combination device for low-strain detection of foundation piles includes a cylindrical simulation pile 10, and the outside of the simulation pile 10 is provided with a shading bag 20. The shading bag 20 is preferably a black cloth bag, and the shading bag 20 is used. to cover the simulated pile 10, avoiding the defects of the design around the simulated pile 10 from being directly viewed by the test subject. Wherein, a light-shielding tube may also be used instead of the light-shielding bag 20 , and the light-shielding tube is sleeved on the outside of the simulation pile 10 .

[0055] The sensor 30 is installed on the top of the simulation pile 10, the top of the light-shielding bag 20 is provided with a mounting hole for the simulation pile 10 to pass through, and the light-shielding bag 20 and the simulation pile 10 are bound and fixed. The bottom of the dummy pile 10 is installed on the ground. The sen...

Embodiment 2

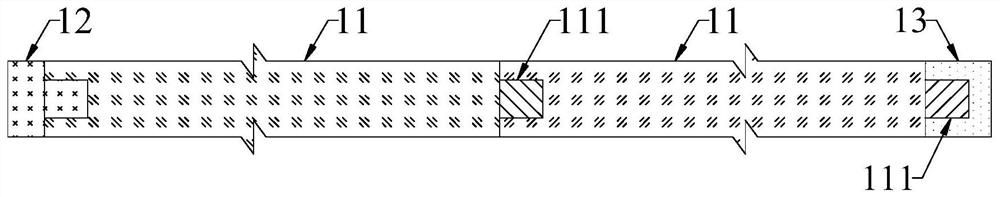

[0057] This embodiment simulates the simulated pile 10 of the complete structure, such as Figure 2-5 As shown, the simulated pile 10 includes at least one first pile body 11, the outer circumference of the first pile body 11 is a cylindrical structure, and the head end of the first pile body 11 is provided with a first pile body protruding outward. A threaded column 111, the maximum diameter of the first threaded column 111 is smaller than the diameter of the first pile body 11, and the tail end of the first pile body 11 is provided with a first screw hole 112 matching the first threaded column 111 ; The simulated pile 10 also includes a public head 12 and a female head 13, the public head 12 includes a cylindrical first cylinder 121, and the diameter of the first cylinder 121 is equal to the diameter of the first pile body 11 , the first end of the first column 121 is provided with a second threaded column 122 matching the first screw hole 112; the female head 13 has a cylin...

Embodiment 3

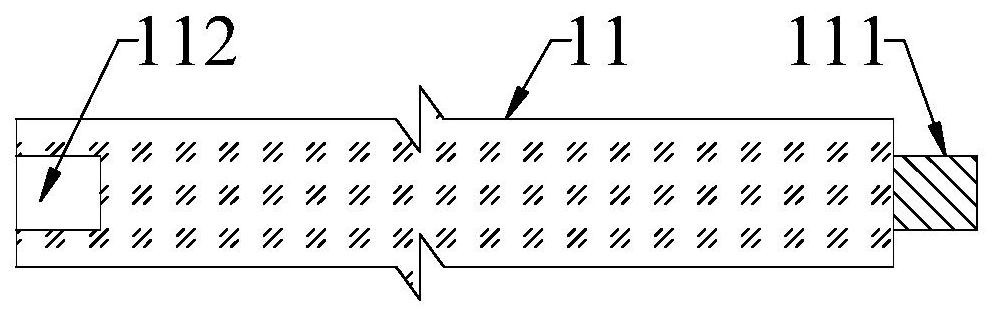

[0062] like Figure 6 As shown, the outer circumference of the first pile body 11 is provided with an annular groove 113 along the outer circumference of the first pile body 11 in a circular structure. The annular groove 113 is used to simulate the "neck-in" defect at the first pile body 11 .

[0063] In this embodiment, there are two first pile bodies 11 with "necking" defects, that is, two first pile bodies 11 provided with annular grooves 113, and the two first pile bodies 11 are connected to have two "necking" defects. Necking" defect simulated pile 10, such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com