Power storage battery plastic shell corrosion resistance testing device and method

A technology of power battery and testing device, applied in the direction of measuring device, lead-acid battery, testing material hardness, etc., can solve the problems of easy corrosion of battery shell, leakage of oily substances, cracking, etc., to avoid batch quality problems, The effect of the convenience of the test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

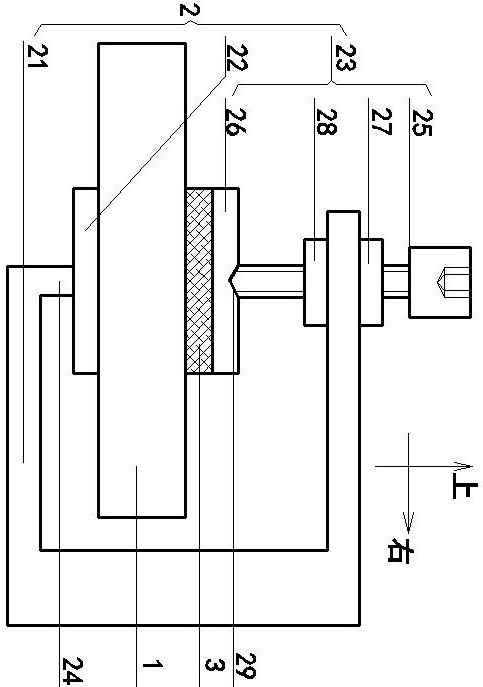

[0027] Embodiment 1: as figure 1 , figure 2 The shown one kind of test device for corrosion resistance of the molded case of power storage battery includes a middle cover 1 and a pressing device 2. The pressing device 2 includes a fixing frame 21, a horizontal pallet 22, and a locking device 23. The fixing The frame 21 is U-shaped and the U-shaped opening faces to the left. The left end of the bottom plate is integrally connected with a vertical support rod 24. The top of the support rod 24 is welded with a horizontal pallet 22 on which a middle Cover 1; the left end of the top plate of the fixing frame 21 is provided with a locking device 23, and the locking device 23 fixes the rubber pad 3 at the center of the top surface of the middle cover 1; the locking device 23 includes locking bolts 25. Pressing plate 26, limit nut A27, limit nut B28, the screw rod of the locking bolt 25 runs through the top plate of the fixing frame 21 from top to bottom and is connected with the pr...

Embodiment 2

[0039] 1. Cut out a square rubber pad with a side length of 25mm, and place it on the top surface of the middle cover;

[0040] 2. Place the pressure plate on the top surface of the rubber pad, and use the torque wrench to tighten the locking bolt. When the locking bolt presses the pressure plate, the torque value of the control torque wrench is: 20Nm;

[0041] 3. The whole device is placed in a high and low temperature box, the temperature is set at 60°C, and the time is 60h;

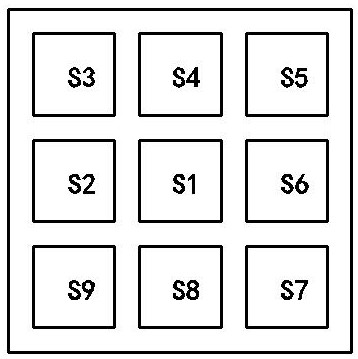

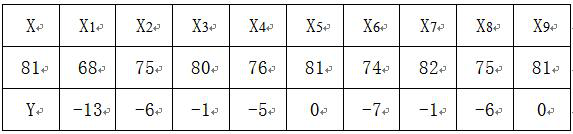

[0042]4. After the time is over, take out the whole device, let it cool down to room temperature 25°C, and take out the rubber pad, observe the change of the surface color of the rubber pad and compare the average hardness values X1, X2, X3, X4, X5, X6, X7, The difference Y between X8, X9 and X (set the value of X to be 81):

[0043]

[0044] In terms of color change, the area of S1 turns yellow, and it is preliminarily judged that it has been corroded; and according to the comparison of the da...

Embodiment 3

[0047] 1. Cut out a square rubber pad with a side length of 25mm, and place it on the top surface of the middle cover;

[0048] 2. Place the pressure plate on the top surface of the rubber pad, and use the torque wrench to twist the locking bolt. When the locking bolt presses the pressure plate, the torque value of the torque wrench is controlled to 20Nm;

[0049] 3. The whole device is placed in a high and low temperature box, the temperature is set at 60°C, and the time is 60h;

[0050] 4. After the time is over, take out the whole device, let it cool down to room temperature 25°C, and take out the rubber pad, observe the change of the surface color of the rubber pad and compare the average hardness values X1, X2, X3, X4, X5, X6, X7, The difference Y between X8, X9 and X (set the value of X to be 81):

[0051]

[0052] In terms of color change, there is no obvious change in the S1 area, and it is preliminarily judged that it has not been corroded; and according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com