A two-for-one twisting and plying machine spindle transmission device

A technology of spindle drive and plying machine, applied in the direction of transmission device, rope-making auxiliary device, mechanical equipment, etc., to achieve the effect of simplified mechanism, rigidity and stability, and shortened size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

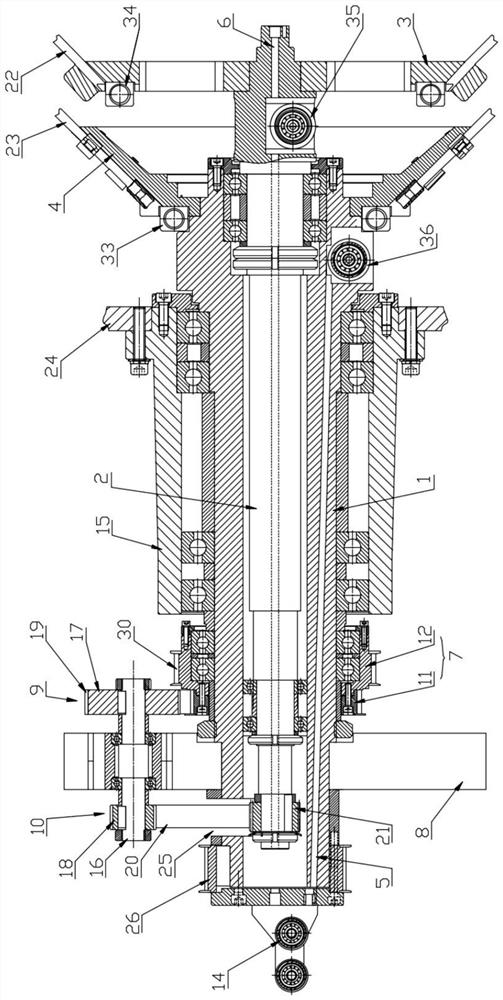

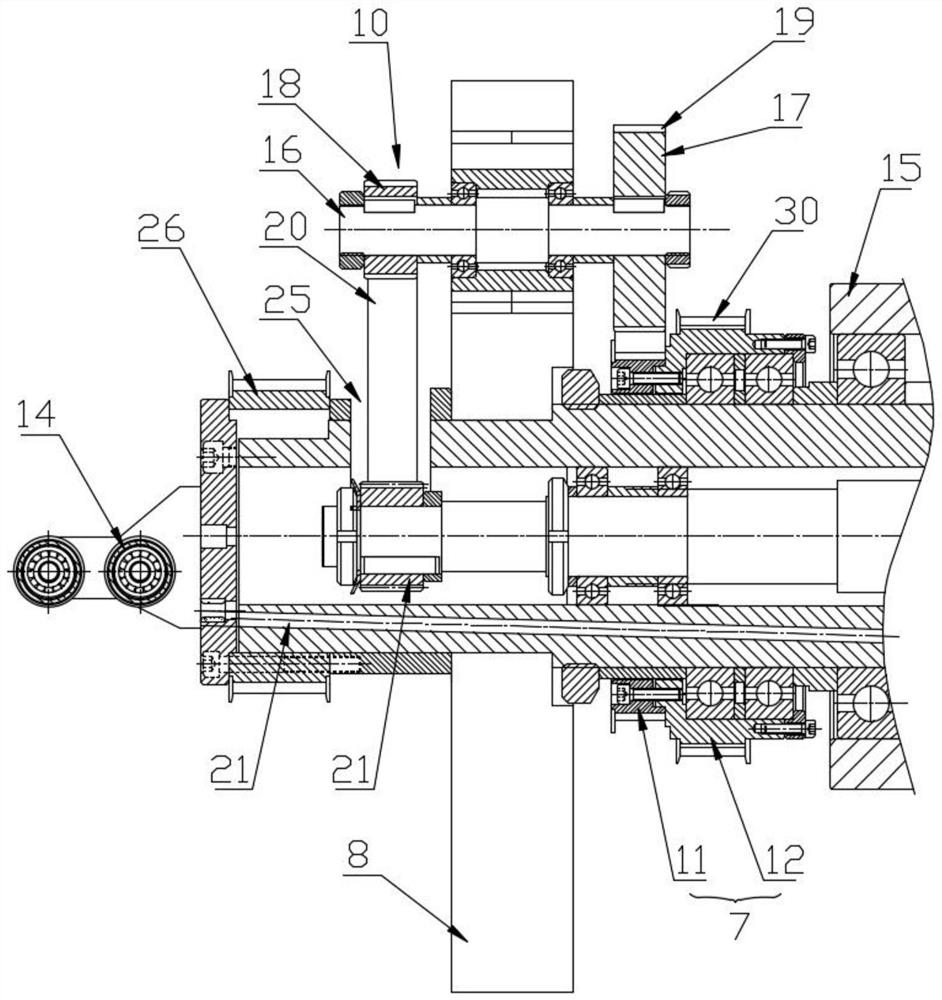

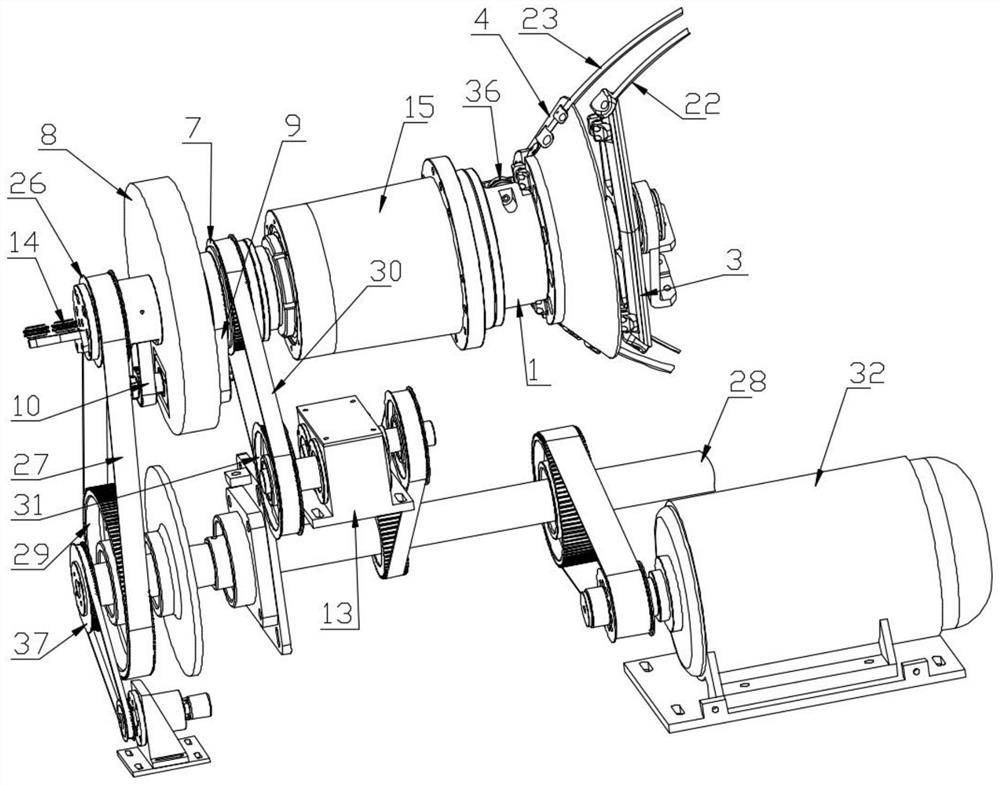

[0033] refer to Figure 1 to Figure 7 , the present invention provides a two-for-one twisting and plying machine main shaft transmission device, comprising: a hollow outer main shaft 1 and an inner mandrel 2; the inner mandrel 2 is set inside the outer main shaft 1, and one end thereof protrudes from the outer main shaft 1 and is connected with a small flywheel Disc 3; outer main shaft 1 is connected with a large flywheel disc 4 near the end of the small flywheel disc 3; the small flywheel disc 3 and the large flywheel disc 4 are used for twisting strands. A double pulley set 7 is rollingly installed on the outer circumference of the outer main shaft 1, and a rotating bearing seat 8 is fixedly installed on one side of the outer main shaft 1 on the side of the double pulling pulley set 7, and the first shifting gear set eccentrically is installed on the rotating bearing seat 8. The pulley set 9 and the second speed change pulley set 10, the second speed change pulley set 10 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com