A two-dimensional material transfer method based on a stepped substrate

A technology of two-dimensional materials and transfer methods, which is applied in the field of material transfer, can solve the problems of the contact area between two-dimensional materials and the substrate becomes smaller and cannot be transferred, and achieve the effects of increasing the bonding force, improving the success rate, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

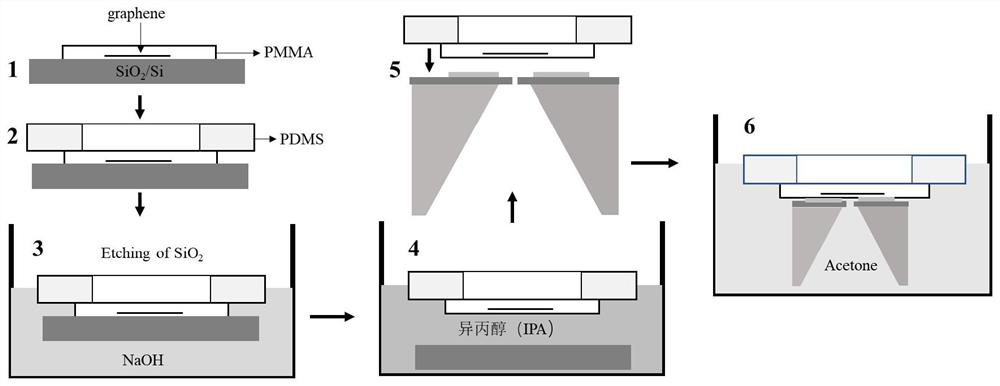

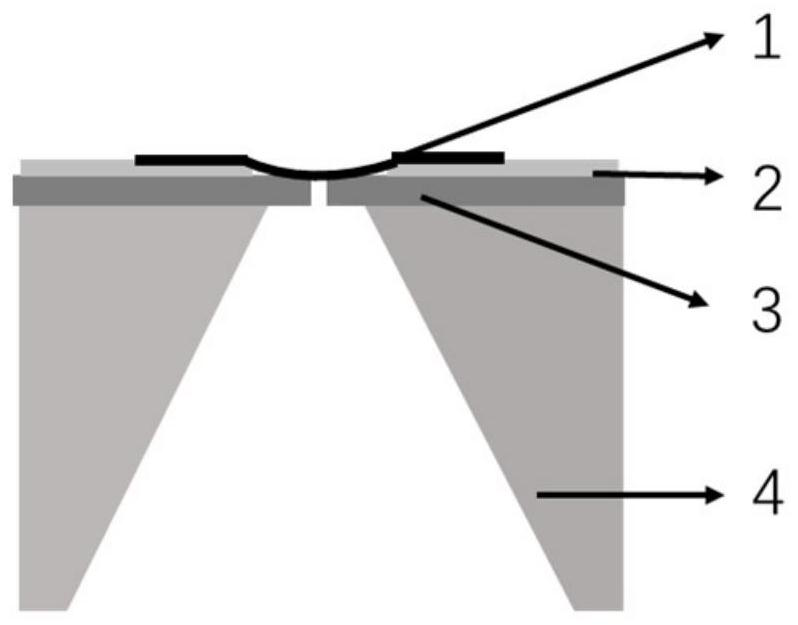

[0020] like figure 1 The two-dimensional material transfer method based on the stepped substrate shown includes the preparation and transfer process of the two-dimensional material. The preparation of the two-dimensional material adopts the mechanical lift-off method, and the transfer adopts the improved wet transfer method. In this example, the two-dimensional material is to be transferred. The material is graphene.

[0021] Specifically include the following steps:

[0022] (1) Graphene is peeled off on a silicon oxide / silicon substrate to form a graphene layer, preferably a silicon oxide / silicon substrate with a thickness of 285 nanometers of silicon oxide, and spin-coating 4% PMMA benzene on the graphene layer Diethyl ether solution, spin-coated 2 times to ensure the thickness of the PMMA film is 0.5 μm.

[0023] Graphene can also be exfoliated on PMMA first and then pressed onto a silicon oxide / silicon substrate.

[0024] (2) Under the optical microscope, the graphene / ...

Embodiment 2

[0034] The present invention is based on a two-dimensional material transfer method with a stepped substrate, which specifically includes the following steps:

[0035] (1) peel off the graphene on the silicon oxide / silicon substrate to form a graphene layer, spin-coat PMMA on the graphene layer, and spin-coat twice to ensure that the thickness of the PMMA film is 0.65 microns;

[0036] (2) Under the optical microscope, the graphene / PMMA layer was pressed tightly onto the punched PDMS square, and the graphene was located in the center of the hole; a cylindrical puncher was used, and the hole diameter was 2.5 mm.

[0037] (3) Put the whole sample obtained into sodium hydroxide solution to etch silicon oxide to release graphene / PMMA / PDMS; the mass fraction of sodium hydroxide solution is 33%.

[0038] (4) fish out the graphene / PMMA / PDMS and put it into isopropanol solution for cleaning, then fish out the graphene / PMMA / PDMS, align the graphene with the target position and press it...

Embodiment 3

[0041] The present invention is based on a two-dimensional material transfer method with a stepped substrate, which specifically includes the following steps:

[0042] (1) peel off the graphene on the silicon oxide / silicon substrate to form a graphene layer, spin-coat PMMA on the graphene layer, and spin-coat 3 times to ensure that the thickness of the PMMA film is 0.8 microns;

[0043] (2) Under an optical microscope, the graphene / PMMA layer was pressed onto the punched PDMS square, and the graphene was located in the center of the hole; a cylindrical puncher was used, and the hole diameter was 3 mm.

[0044] (3) Putting the obtained whole sample into sodium hydroxide solution to etch silicon oxide to release graphene / PMMA / PDMS; the mass fraction of sodium hydroxide solution is 35%.

[0045] (4) fish out the graphene / PMMA / PDMS and put it into isopropanol solution for cleaning, then fish out the graphene / PMMA / PDMS, align the graphene with the target position and press it with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com