Railway freight car side bearing and railway freight car bogie

A technology for bogies and trucks, applied in the field of rail vehicles, can solve problems such as inability to effectively avoid sand, gravel and dust, increase maintenance and replacement costs, and acid-base environmental pollution, so as to avoid sand, gravel and dust interference, and reduce maintenance and replacement. the cost and the effect of avoiding acid-base pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

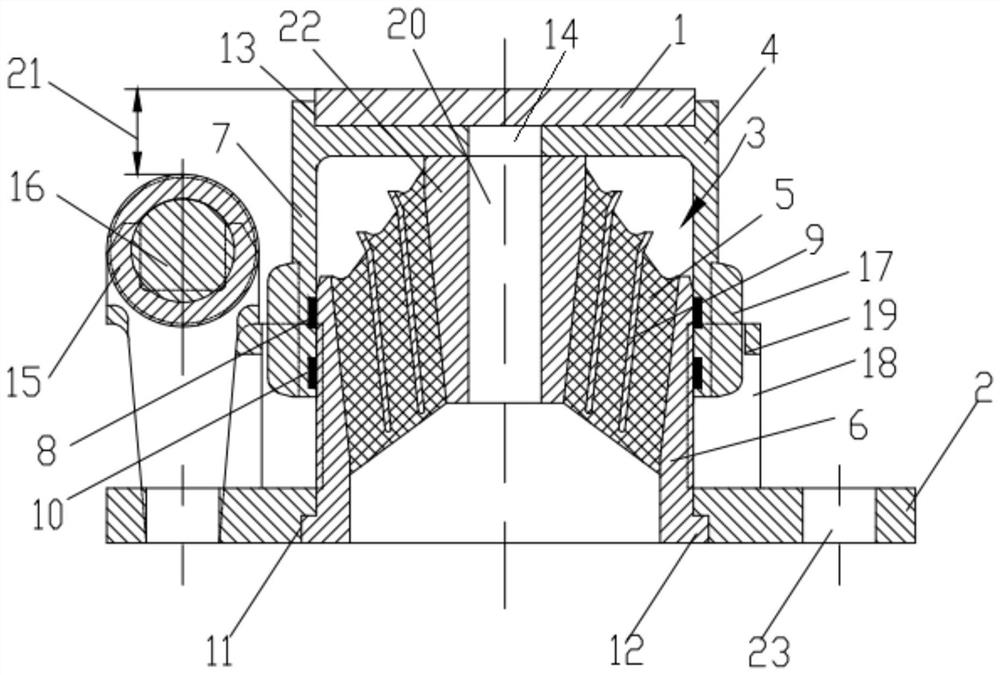

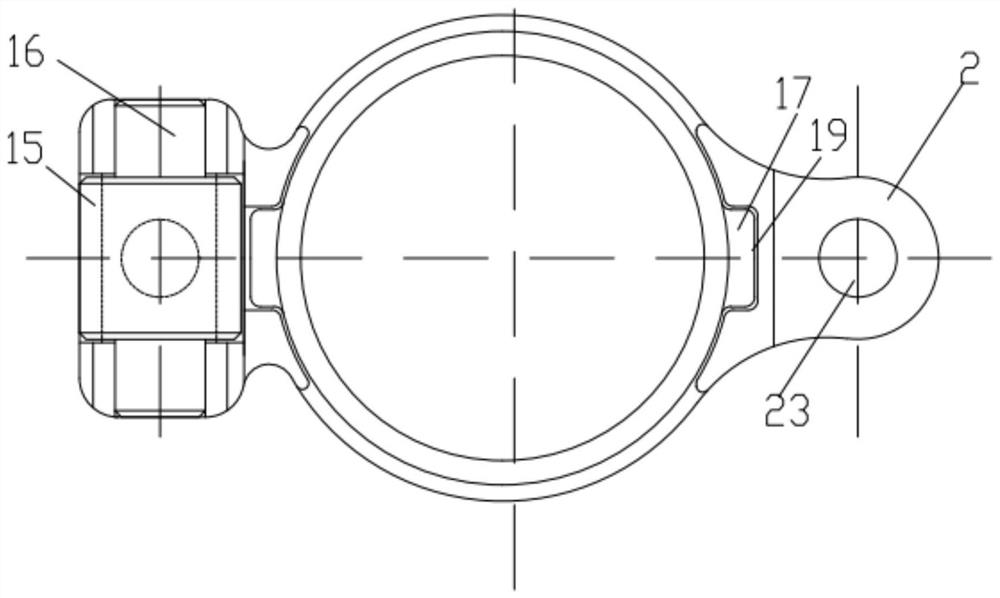

[0035] like Figure 1-2 As shown, the embodiment of the present invention discloses a side bearing of a railway freight car, including a wear plate 1, a side bearing seat 2, a rubber elastic body 3, a roller assembly and a cover plate 4, and the wear plate 1 is installed on the cover plate 4 On the side, the roller assembly is installed on the side bearing 2. Specifically, the roller assembly includes a roller 15 and a roller shaft 16. The roller 15 is sleeved on the roller shaft 16. The roller 15 is connected to the wear plate 1 The distance between the surfaces is the side bearing vertical stroke 21. The rubber elastic body 3 includes an inner core 22, a rubber layer 5 and an outer cover 6 which are sequentially sleeved from the inside to the outside. The outer cover 6 is located under the inner core 22. The inner core 22, rubber The layer 5 and the jacket 6 are vulcanized in one piece. The rubber layer 5 is embedded with multiple metal inner jackets 9, which can effectively...

Embodiment 2

[0043] like Figure 4 As shown, in this embodiment, the main structure is similar to Embodiment 1, and the connection method with the bogie 29 is also the same. The rubber elastic body 3 is closed, the underside of the cover plate 4 is provided with a cover plate sleeve hole 24, the side bearing seat is provided with a side bearing seat sliding sleeve 25, and the upper end of the outer sleeve 6 is sleeved in the cover plate sleeve hole 24 inside, and lean against the top in the socket hole 24 of the cover plate, the lower end is slid in the sliding sleeve 25 of the side bearing seat, and there is a gap between the sliding sleeve 25 of the side bearing seat and the overcoat 6 to prevent the sliding sleeve 25 of the side bearing seat and The guide belt 8 rubbed by the overcoat 6 can solve the wear problem between the side bearing sliding sleeve 25 and the overcoat 6 while sealing the rubber elastic body 3 . In the specific setting of the guide belt 8, there is a gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com