Antibacterial barrier BOPET film and preparation method thereof

A barrier and film technology, applied in the field of antibacterial barrier BOPET film and its preparation, can solve the problems of poor optical performance, large film haze, low production efficiency, etc., and achieve excellent antibacterial effect, reduce haze, and improve barrier performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

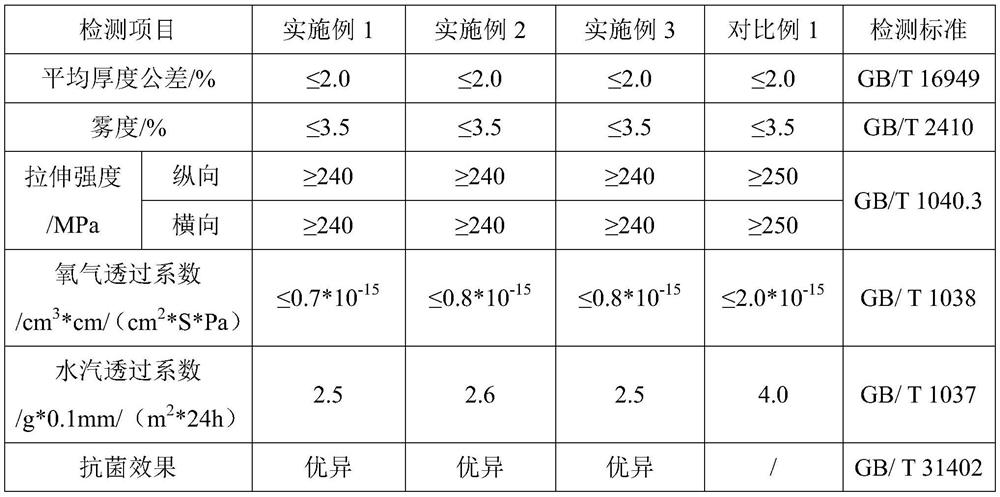

Examples

Embodiment 1

[0026] An antibacterial barrier BOPET film is composed of an upper surface layer, a core layer and a lower surface layer; its thickness is 15 μm, and the thicknesses of the upper and lower surface layers each account for 12% of the total thickness of the film.

[0027] The upper and lower surface layers are antibacterial layers, which are made of the following raw materials in weight percentage: 1.0% of silver-loaded carbon nanotubes, 0.3% of glass beads, and the balance is polyester slices; the average particle size of glass beads is 1.5 μm .

[0028] The core layer is a barrier layer, which is made of the following raw materials in parts by weight: 10% of EVOH, 0.8% of nanometer montmorillonite, and the rest is polyester chips.

[0029] The present invention also proposes a preparation method for the above-mentioned antibacterial barrier BOPET film, comprising the following steps:

[0030] S1. Mix EVOH, nano-montmorillonite, and polyester chips evenly, extrude through a twi...

Embodiment 2

[0035] An antibacterial barrier BOPET film is composed of an upper surface layer, a core layer and a lower surface layer; its thickness is 18 μm, and the thicknesses of the upper and lower surface layers each account for 13% of the total thickness of the film.

[0036] The upper and lower surface layers are antibacterial layers, which are made of the following raw materials in weight percentage: 1.1% of silver-loaded carbon nanotubes, 0.35% of glass beads, and the balance is polyester slices; the average particle size of glass beads is 1.8 μm .

[0037] The core layer is a barrier layer, which is made of the following raw materials in parts by weight: 12% of EVOH, 0.6% of nanometer montmorillonite, and the rest is polyester chips.

[0038] The present invention also proposes a preparation method for the above-mentioned antibacterial barrier BOPET film, comprising the following steps:

[0039] S1. Mix EVOH, nano-montmorillonite, and polyester chips evenly, extrude through a tw...

Embodiment 3

[0044] An antibacterial barrier BOPET film is composed of an upper surface layer, a core layer and a lower surface layer; its thickness is 20 μm, and the thickness of the upper and lower surface layers each accounts for 14% of the total thickness of the film.

[0045] The upper and lower surface layers are antibacterial layers, which are made of the following raw materials in weight percentage: 1.2% of silver-loaded carbon nanotubes, 0.4% of glass beads, and the balance is polyester slices; wherein, the average particle size of glass beads is 2 μm.

[0046] The core layer is a barrier layer, which is made of the following raw materials in parts by weight: 15% of EVOH, 0.5% of nanometer montmorillonite, and the rest is polyester chips.

[0047] The present invention also proposes a preparation method for the above-mentioned antibacterial barrier BOPET film, comprising the following steps:

[0048]S1. Mix EVOH, nano-montmorillonite, and polyester chips evenly, extrude through a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Stretch temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com