Thin-walled cylinder part assembling and welding supporting device

A supporting device and thin-walled cylinder technology, applied in the field of mechanical processing, can solve the problems of non-reusable use and difficult disassembly of welding support devices, etc., achieve good social benefits, improve welding efficiency, and ensure the effect of welding assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

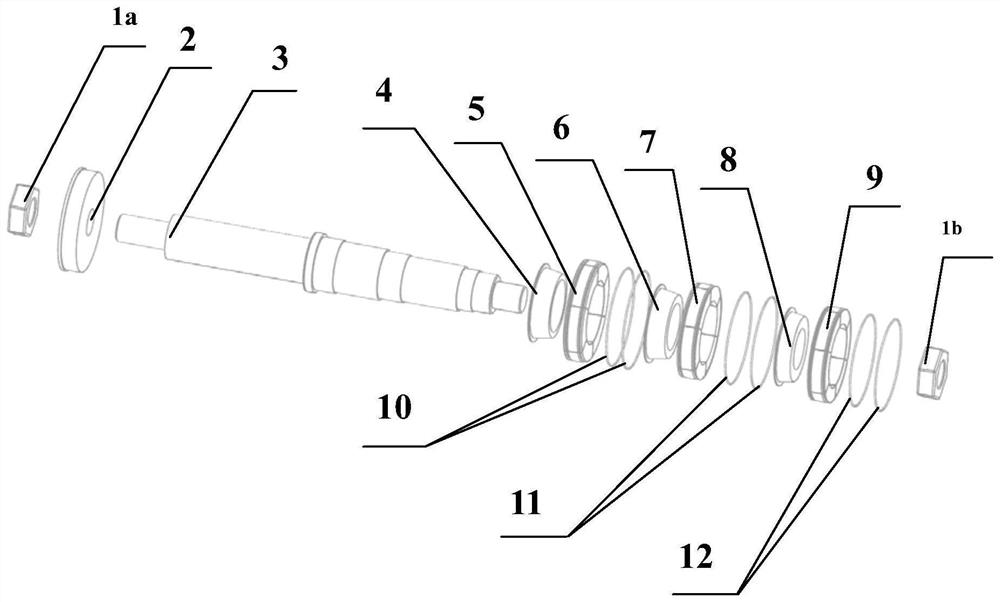

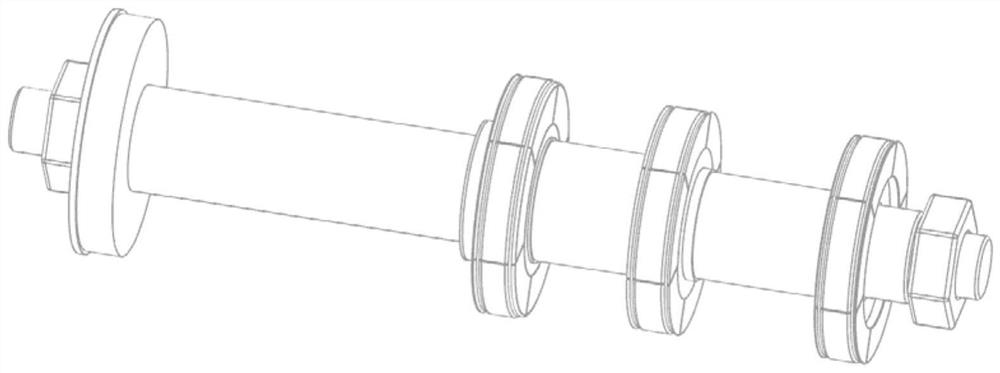

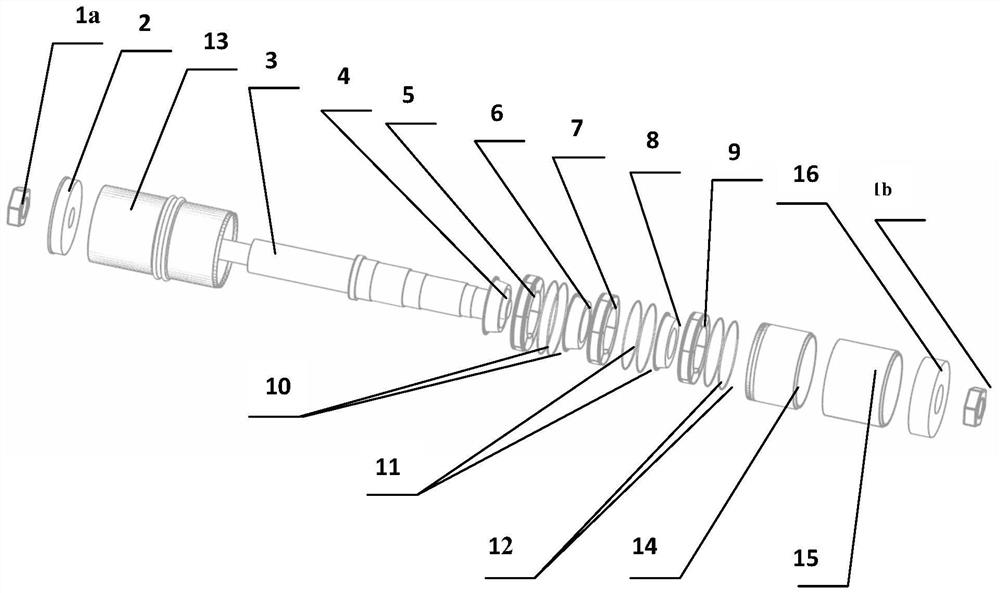

[0072] The supporting device for assembly welding of thin-walled cylindrical parts provided by the present invention includes a nut, an end face positioning ring, a mandrel, a second positioning ring, a first spacer, a second spacer, a third positioning ring, a fourth positioning ring, the third spacer, the first elastic fastening ring, the second elastic fastening ring, and the third elastic fastening ring. The mandrel is a stepped shaft part, on which a fastening thread and a positioning stepped surface for installation are provided. The locating ring is an intermediate locating part, which has multiple groups, and is installed on the locating cylindrical surface of the mandrel, and has a mounting taper surface on the outside. Pad block is a kind of special supporting part, there are many groups, each group of pad block is composed of six loose blocks, the inner hole cone surface matches the outer cone surface of the positioning ring, and the outer cylindrical surface matche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com