A deep two-stage repair and recovery method for heavy metal soil

A recovery method and technology for heavy metals, applied in the field of soil remediation, can solve problems such as low-cost remediation methods, low cost, difficult and effective targeted remediation, etc., and achieve the effect of reducing daily maintenance and charging, promoting root respiration, and improving remediation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

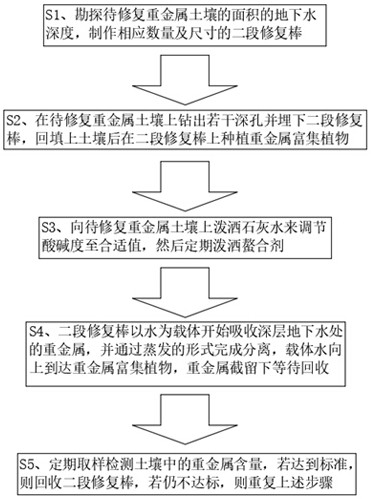

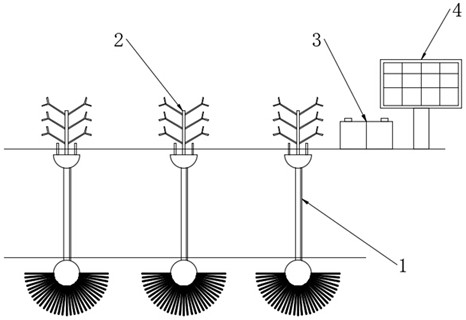

[0048] see Figure 1-2 , a deep two-stage repairing and recycling method for heavy metal soil, comprising the following steps:

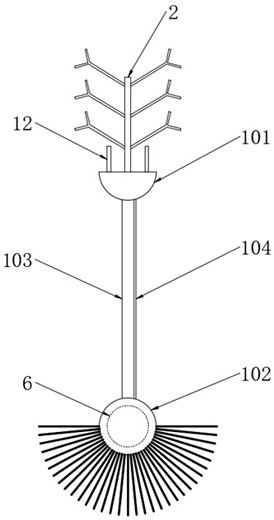

[0049] S1. Investigate the groundwater depth of the area to be repaired with heavy metal soil, and make two-stage repair rods 1 of corresponding quantity and size;

[0050] S2. Drill some deep holes on the heavy metal soil to be repaired and bury the second-stage repair rod 1, and plant heavy metal enrichment plants 2 on the second-stage repair rod 1 after backfilling the soil;

[0051] S3. Sprinkle lime water on the heavy metal soil to be repaired to adjust the pH to a suitable value, and then regularly sprinkle the chelating agent;

[0052] S4. The second-stage repair rod 1 starts to absorb the heavy metals in the deep groundwater with water as the carrier, and completes the separation through evaporation. The carrier water reaches the heavy metal enrichment plants upwards, and the heavy metals are retained for recovery;

[0053] S5. Periodically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com