Construction waste recovery treatment device

A technology for recycling and processing construction waste, applied in construction waste recycling, grain processing, recycling technology, etc., can solve the problems of waste of land resources, application limitations, uneven crushing particle size, etc., and achieve the effect of improving processing efficiency and processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

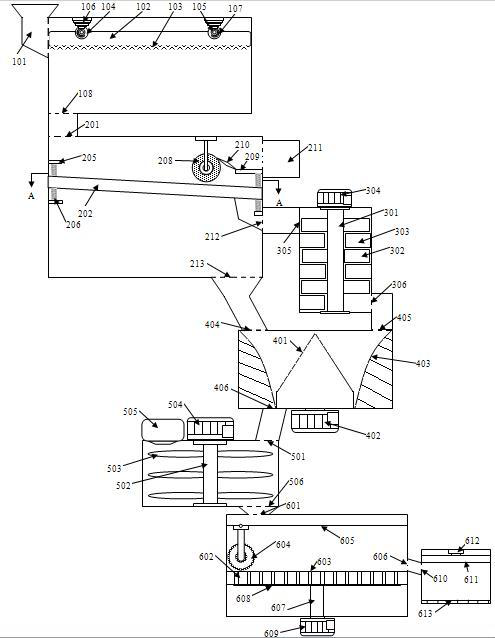

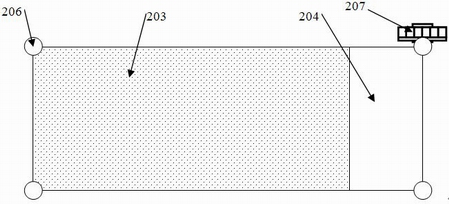

[0032] Further explanation in conjunction with accompanying drawings: Figure 1-Figure 5 The construction waste recycling and processing device of this embodiment includes a hammering chamber, a magnetic separation and screening chamber, a crushing chamber, a grinding chamber, a mixing chamber and a brick-forming component.

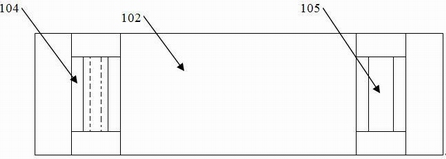

[0033] Such as figure 1 and image 3 As shown, the hammering chamber includes a garbage inlet 101, a hammering chamber casing, a hammering ingot 102, an arc groove 104, a receiving cross bar, a receiving bearing 105, a telescopic rod 106, a rotating hook 107 and a hammering chamber outlet 108 The garbage inlet is arranged at the top of the side wall of the hammering chamber shell, the hammering ingot is placed horizontally inside the hammering chamber shell, and the bottom surface of the hammering ingot is roughened to form a hammering surface 103. There are two curved grooves on the top of the ingot, such as image 3 As shown, there is a cross bar ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com