A kind of syngas desulfurizer and its preparation method and application

A desulfurizing agent and synthesis gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low desulfurization accuracy, increase the difficulty of production control, increase investment costs and operating costs, and achieve good structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

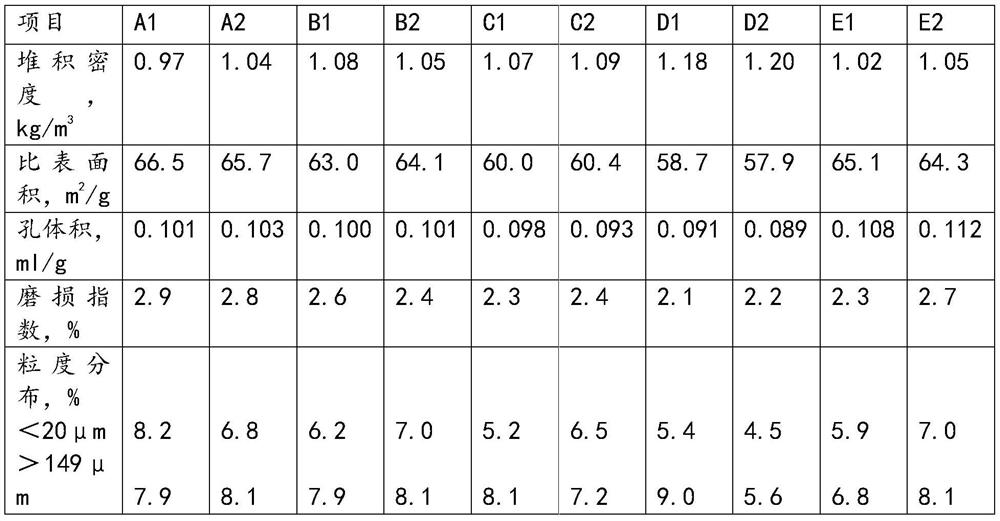

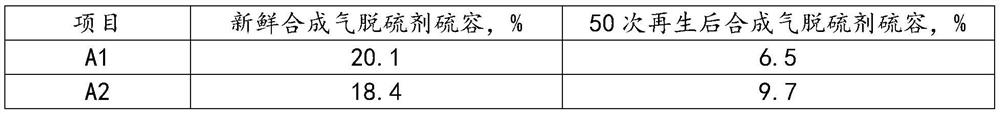

Examples

preparation example Construction

[0052] In a second aspect, an embodiment of the present invention provides a method for preparing the above-mentioned syngas desulfurizer, comprising the following steps: forming and roasting a slurry containing precursors of each component to obtain a syngas desulfurizer.

[0053] The concrete steps of the preparation of above-mentioned syngas desulfurizer are as follows:

[0054] Add a certain amount of deionized water to the alumina sol or silica sol, then slowly add pseudo-boehmite and / or hydrated titanium dioxide powder and stir for 6-10 hours to obtain a slurry, and continue to add metered phosphoric acid and / or ammonium phosphate and / or and / or ammonium hydrogen phosphate and / or ammonium dihydrogen phosphate and / or boric acid, copper oxide and / or gallium nitrate and / or chloride, nano basic zinc carbonate and / or nano oxide Zinc and / or zinc nitrate and / or zinc chloride, etc., the whole slurry is stirred and homogenized for 6-10 hours, and the solid content of the slurry i...

Embodiment 1

[0067] Get aluminum sol 1058g (Al 2 o 3 Content 21%), slowly add ammonium dihydrogen phosphate 27g, copper nitrate 94g, basic zinc carbonate 1500g, then stir for 5.0 hours. Under the conditions of furnace temperature 400°C, outlet temperature 200°C, and spray pressure 4.0MPa, it is spray-dried and shaped. The molded syngas desulfurizer was dried at 150°C for 5.0 hours and calcined at 600°C for 5.0 hours to obtain the syngas desulfurizer E01.

[0068] Dissolve 190g of nickel nitrate and 207g of cobalt nitrate in 600ml of water, soak the synthesis gas desulfurization agent E01 at 50°C for 6 hours, then dry at 110°C for 4 hours, and finally roast at 500°C for 5 hours to obtain the synthesis gas desulfurization Agent E001.

[0069] Syngas desulfurizer E001 is used at normal pressure, temperature 400°C, space velocity 2000h -1 Under certain conditions, the finished synthesis gas desulfurizer E1 can be obtained by reducing it with hydrogen for 60 minutes.

Embodiment 2

[0071] Get aluminum sol 1184g (Al 2 o 3 Content 21%), slowly add 27g of ammonium dihydrogen phosphate, 80g of copper nitrate, 1500g of basic zinc carbonate, and then stir for 5.0 hours. Under the conditions of furnace temperature 400°C, outlet temperature 200°C, and spray pressure 4.0MPa, it is spray-dried and shaped. The shaped adsorbent was dried at 150°C for 5.0 hours and calcined at 600°C for 5.0 hours to obtain the synthesis gas desulfurizer E02.

[0072] Dissolve 138g of nickel nitrate, 41g of ammonium paramolybdate, and 132g of cobalt nitrate in 600ml of water, use this solution to soak the synthesis gas desulfurizer E02 at 50°C for 6 hours, then dry at 110°C for 4 hours, and finally roast at 500°C for 5 hours. hours to get the synthesis gas desulfurizer E002.

[0073] Syngas desulfurizer E002 is used at normal pressure, temperature 400°C, and space velocity 2000h -1 Under certain conditions, the finished synthesis gas desulfurizer E2 can be obtained by reducing it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com