Flexible and dissolvable solid sheet article

A kind of product and solid technology, applied in the field of solid products, can solve the problems of limiting the freedom of formulation, suboptimal, less expected cleaning performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0238] Example 1: Exemplary formulation of a flexible and dissolvable solid sheet

[0239] The following are exemplary formulations of flexible and dissolvable solid sheets of the present invention that exhibit satisfactory film-forming properties, storage stability, and cleaning benefits:

[0240] Table A

[0241] Composition (weight%) A B C D E F G polyvinyl alcohol 1

21 18 21 15-25 15-25 15-25 15-25 polyvinyl alcohol 2

-- 6 -- -- -- -- -- glycerin 3 3.5 3 2-10 2-10 2-10 2-10 C 12 LAS

53 40 -- 25-50 25-40 0-10 0-10 ST 2 S

-- 0 53 0-10 0-10 40-60 25-40 Sodium Laureth-3 Sulfate 10 4.6 10 20-35 1-4 5-20 20-35 C 12 -C 14 Ethoxylated Alcohol

10 18 10 5-15 15-25 5-25 5-15 water margin margin margin margin margin margin margin

[0242] 1. A homopolymer with a degree of polymerization of about 1700

[0243] 2. A homopolymer with a deg...

Embodiment 2

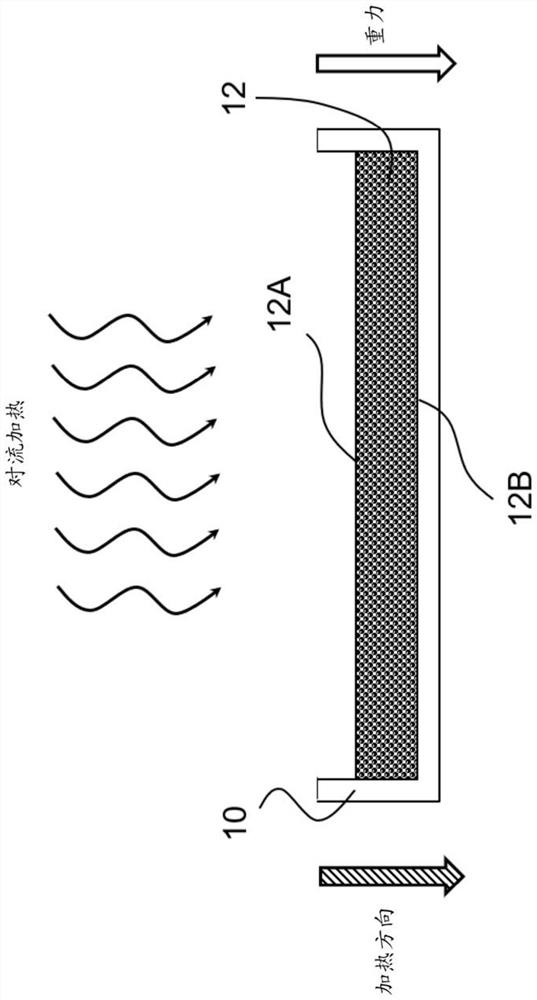

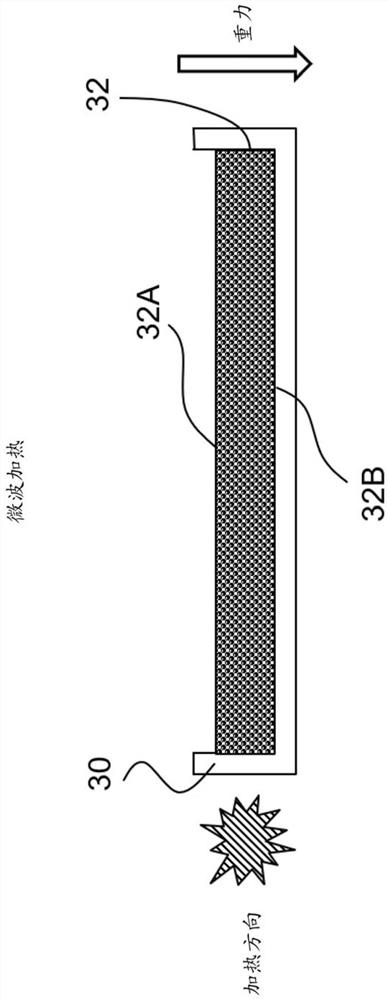

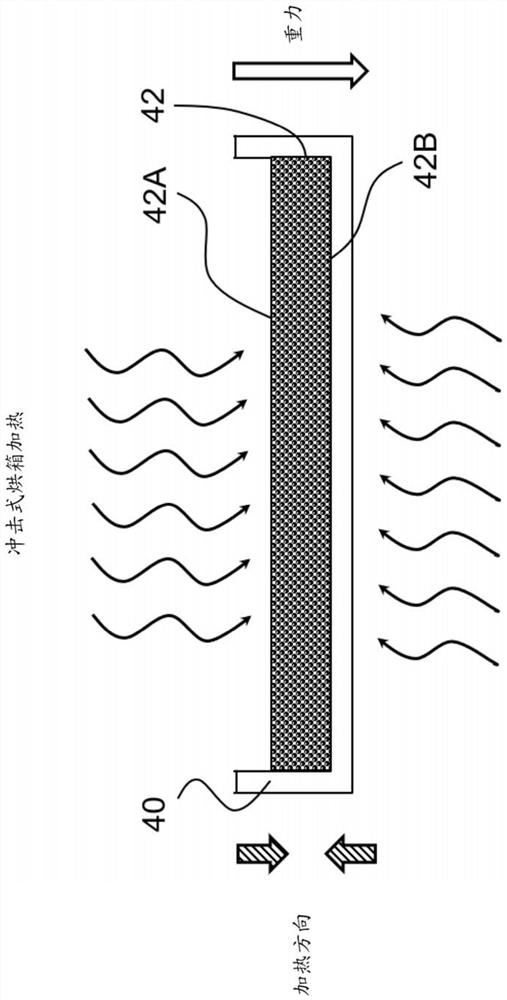

[0244] Example 2: Different OCF Structures of Solid Sheets Produced by Different Heating / Drying Apparatus

[0245] Wet premixes were prepared with the following surfactant / polymer compositions as described in Table 1 below.

[0246] Table 1

[0247]

[0248] The viscosity of the wet premix composition as described in Table 1 was about 14309.8 cps. After aeration, the average density of such an aerated wet premix is about 0.225 g / cm 3 .

[0249] A flexible porous dissolvable solid sheet A was prepared from the above wet premix described in Table 1 by using a continuous aerator (Aeros) and a rotary drum dryer with the following settings and conditions as described in Table 2 below:

[0250] Table 2

[0251] (tumble dry)

[0252]

[0253] In addition, another flexible porous dissolvable solid sheet I was prepared from the above wet premix described in Table 1 by using a continuous aerator (Oakes) and a mold placed on an impingement oven with the following set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com