Hot extrusion variable volume percentage bearing bush type magnetorheological fluid brake

A magneto-rheological fluid and variable volume technology, which is applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., can solve problems such as poor braking effect, poor brake stability, and performance degradation of magnetorheological fluids, and achieve improved magnetic flow Variable effect, ensuring reliability and stability, and avoiding the effect of braking torque drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

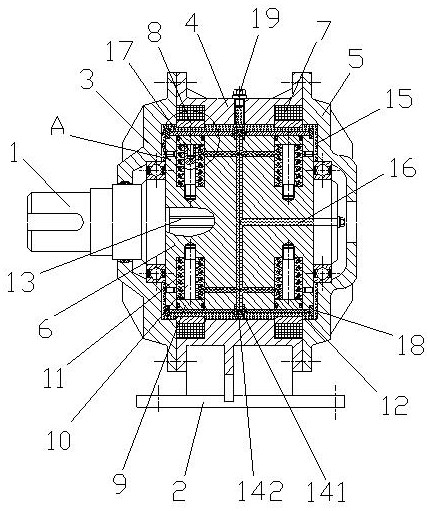

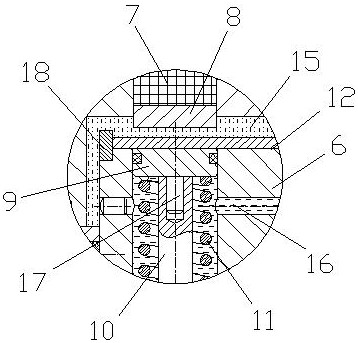

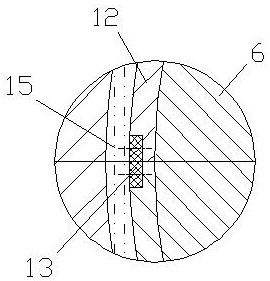

[0024] Example: see Figure 1 to Figure 3 , a magneto-rheological fluid brake with thermal extrusion volume percentage bearing pad, including a brake housing, a brake shaft 1 and a base 2. The brake housing includes a left end cover 3, a brake cylinder 4 and a right end cover 5 connected in sequence, and the base 2 is fixedly connected to the middle part of the brake cylinder 4; the base 2 is used for fixed connection with the ground, etc. to support the brakes. The right end of the brake shaft 1 passes through the left end cover 3 and then extends into the brake housing, and is rotatably connected with the left end cover 3 and the right end cover 5 through bearings, wherein the bearings are sealed bearings to prevent the brake housing from liquid leakage; in order to further improve the leak-proof effect, a felt ring is also provided between the brake shaft 1 and the left end cover 3, and the felt ring is located outside the sealed bearing. The part of the brake shaft 1 ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com