A full-pressure temporary plugging structure and design method for controlling broken particle size

A technology of structural design and particle size, which is applied in earthwork drilling, wellbore/well components, instruments, etc., can solve the problems of uncontrolled particle size, multi-processability of debris, etc., and achieve high compressive strength and high storage strain energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0104] For an API standard 5-1 / 2 吋 sets of working conditions, the working condition size parameters are the outer diameter of the sleeve φ139.7mm, the inner step diameter is 130mm, the internal pass diameter is 120mm, the inner pressure resistance level 75MPa .

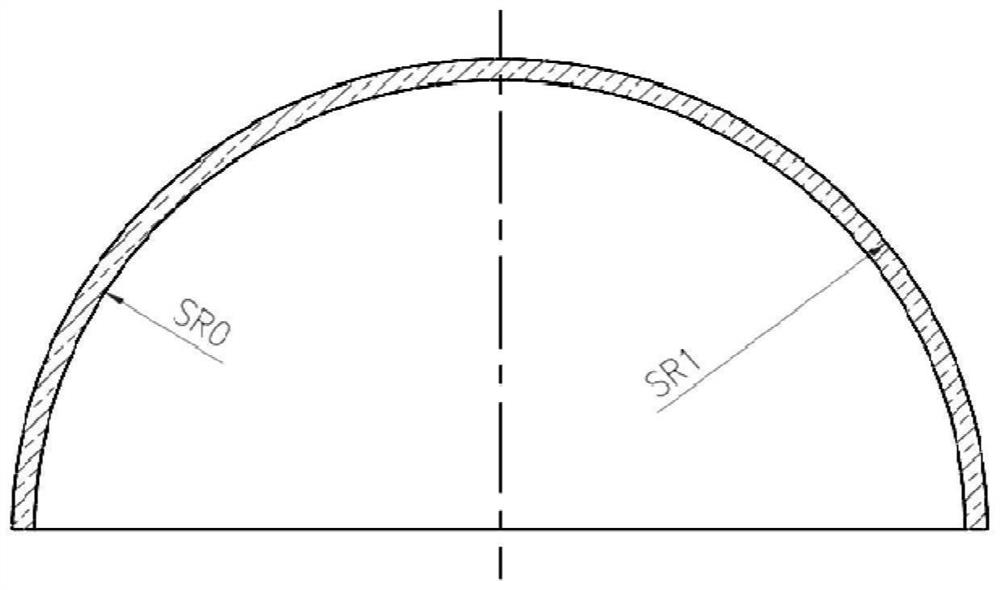

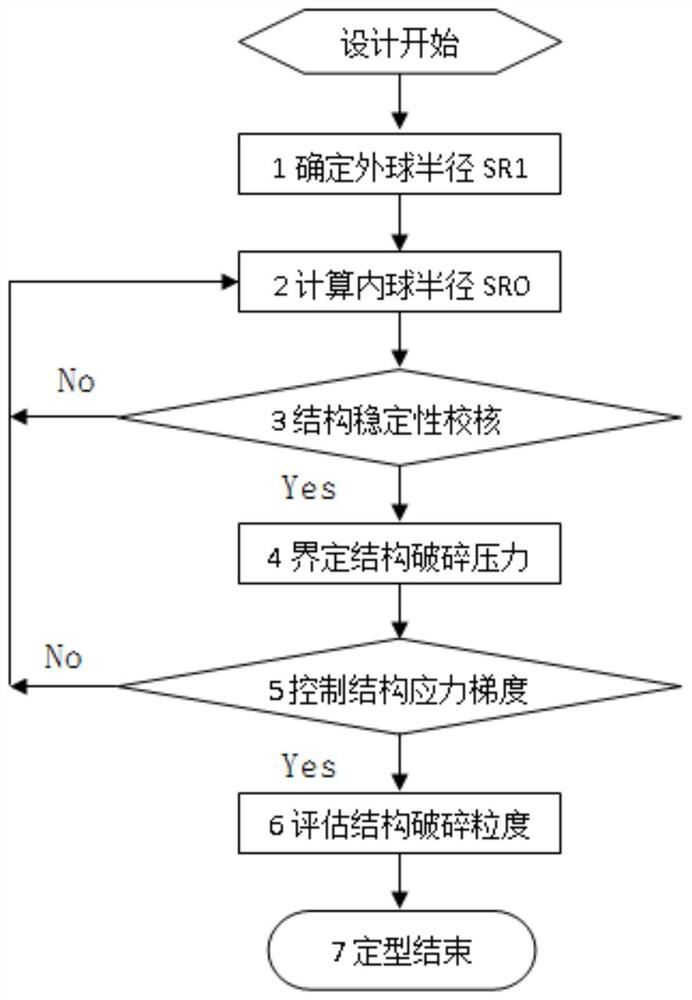

[0105] The temporary structure design method for controlling the crushing particle size is two parameters of the inner spherical radius SR0 and the outer spherical radius SR1 of the hemispherical shell structure. In order to achieve control crushing particle size, it is necessary to design a blind plate with full pressure temporary structure. Concrete blind slab structure design methods include the following steps:

[0106] 1) Outer ball radius SR1 determine

[0107] According to the full pass diameter φ130mm in the casing, the outer spherical radius SR1 is approximately equal to the full-pass radius φ / 2.

[0108] SR1 = φ / 2 = 65mm

[0109] 2) Inner ball radius SR0 calculation

[0110]According to the temporario flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com