Dye coating device for spinning

A coating device and dye technology, which is applied in the direction of processing textile material equipment configuration, textile material processing, textile and paper making, etc., can solve the problems of low dyeing efficiency, high consumption cost, long cloth length, etc. Reduce waste and improve functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

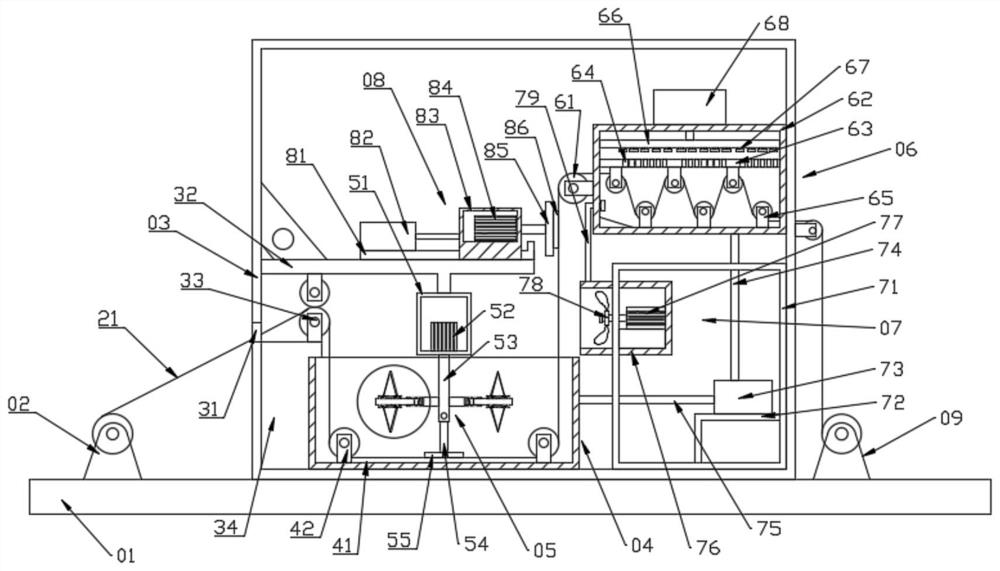

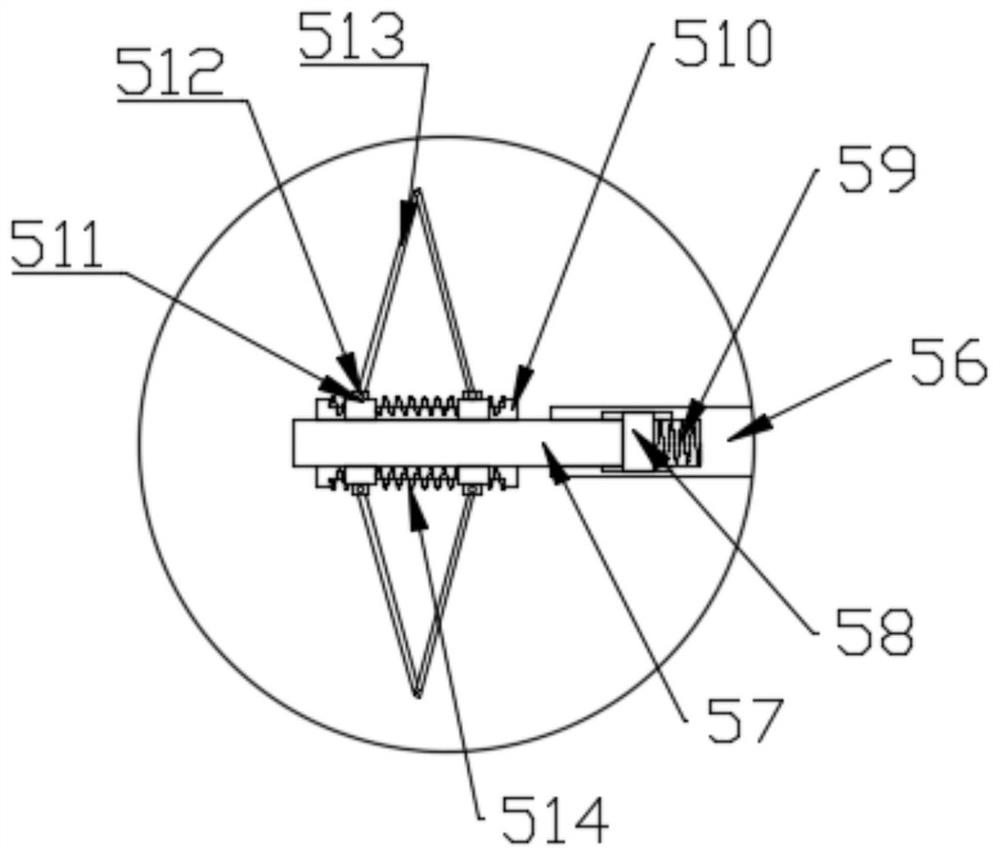

[0026] see Figure 1~4 , in an embodiment of the present invention, a textile dye coating device includes a base 01 on which a feed roll 02, a coating box 03 and a receiving roll 09 are sequentially fixed, and the non-woven fabric wound on the feed roll 02 The cloth 21 is connected with the receiving roll 09 by passing through the coating box 03, wherein the feed roll 02 is used for feeding, and the receiving roll 09 is used for receiving the material, and the coating box 03 is used for dyeing the non-woven fabric 21, Very simple and practical; the coating box 03 is provided with a printing and dyeing assembly 04, a stirring assembly 05 and a drying assembly 06, the stirring assembly 05 is arranged in the printing and dyeing assembly 04 to improve the dyeing effect, and the drying assembly 06 is arranged in The upper right of the printing and dyeing component 04 is used for drying the dyed non-woven fabric 21, which is very simple and practical.

[0027] Further, the coating ...

Embodiment 2

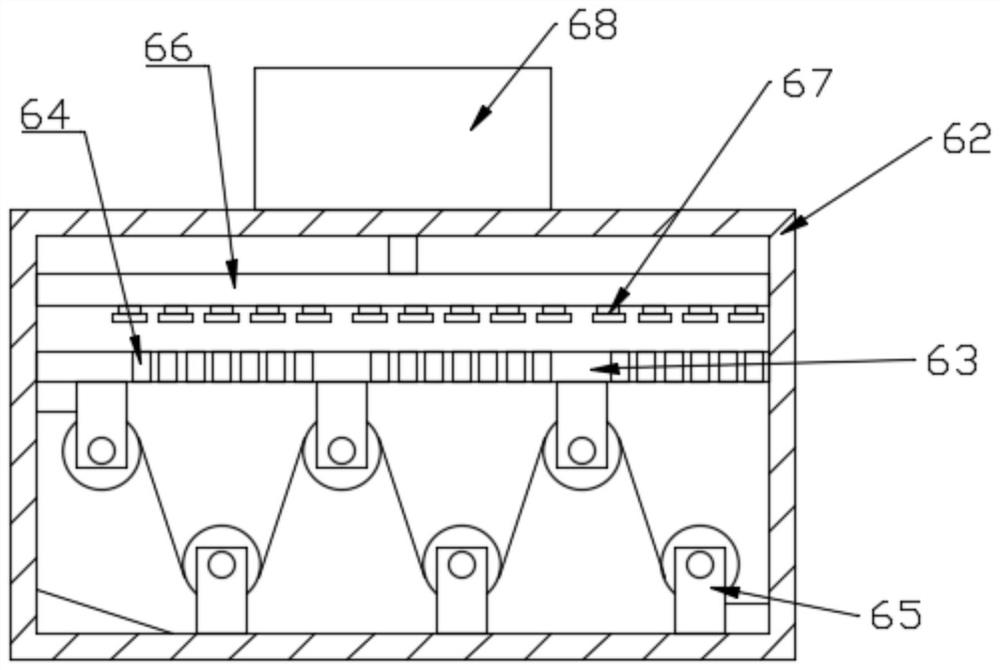

[0036] The coating box 03 is also provided with a smoothing assembly 08 through which the non-woven fabric 21 can be evenly spread. When the non-woven fabric 21 leaves the printing and dyeing assembly 04, a large amount of dye is still attached to the surface. The uniform component 08 can evenly wipe this part of the dye; the smooth component 08 includes a guide rail 81 fixed on the first fixed plate 32, a second fixed box 83 is slidably connected to the guide rail 81, and a second fixed box 83 is fixed in the second fixed box 83. The third motor 84, the output end of the third motor 84 is connected with the smoothing plate 86 on the fixed block 85, can drive the smoothing plate 86 to rotate when the wind hole 64 works, and then smear evenly, the second fixed box 83 and the telescopic cylinder 82 output terminal connection, and then conveniently adjust the position of the second fixed box 83, very simple.

[0037] The working principle of the present invention is: the non-wove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com