Magnetic nano stirrer prepared through electrostatic spinning technology and preparation method and application thereof

An electrospinning technology and a stirrer technology, applied in the field of preparing magnetic nano-stirrers, can solve the problems of inability to achieve rapid mass production, and achieve good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

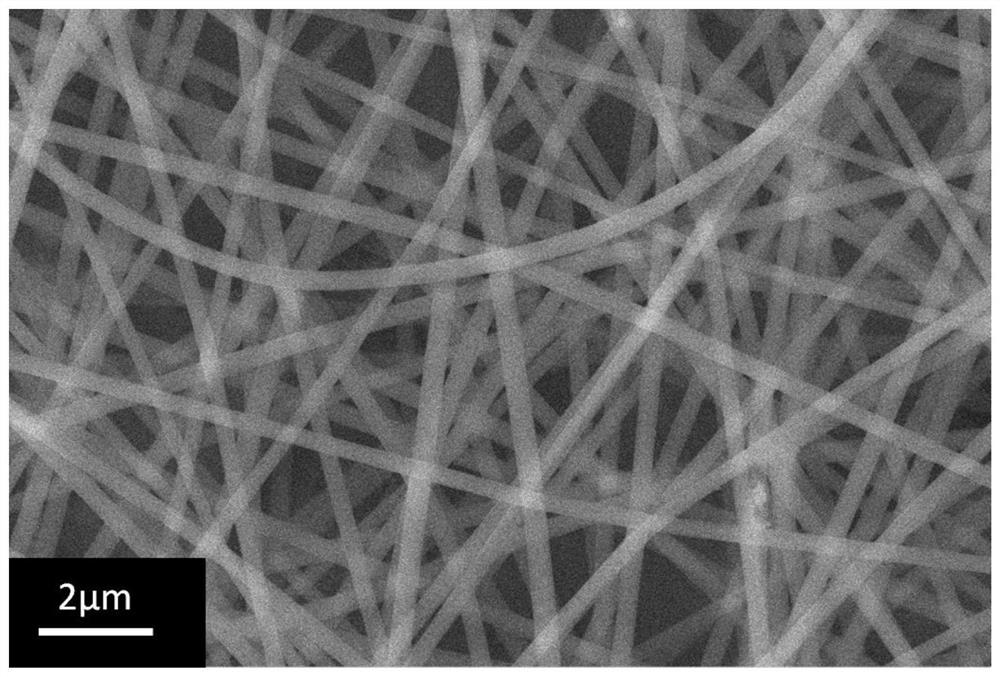

Embodiment 1

[0085] When the iron acetylacetonate high splitting method is used to synthesize larger 45nm particles, the stirring effect is increased.

[0086] 1. Take 1ml of synthesized 45nm Fe 3 o 4 The magnetic nanoparticles were added to the PAN (13wt%) spinning solution, ultrasonically oscillated for 10 minutes, and vortex was rotated and mixed for 20 minutes. Wherein, the preparation method of PAN spinning solution is the same as that of Comparative Example 1.

[0087] 45 nm magnetic nanoparticles were synthesized as follows: Iron(III) acetylacetonate (0.706 g, 2 mM) was added to a mixture of oleic acid (1.129 g, 4 mM) and benzyl ether (15.6 g, 10 mL). The mixture solution was degassed at room temperature for 1 hour. The solution was then heated to 290°C at a rate of 20°C / min under vigorous magnetic stirring. It should be noted that the stirring speed should be fast to prevent the magnetic interaction between the magnetic nanoparticles and the interaction with the stirrer to caus...

Embodiment 2

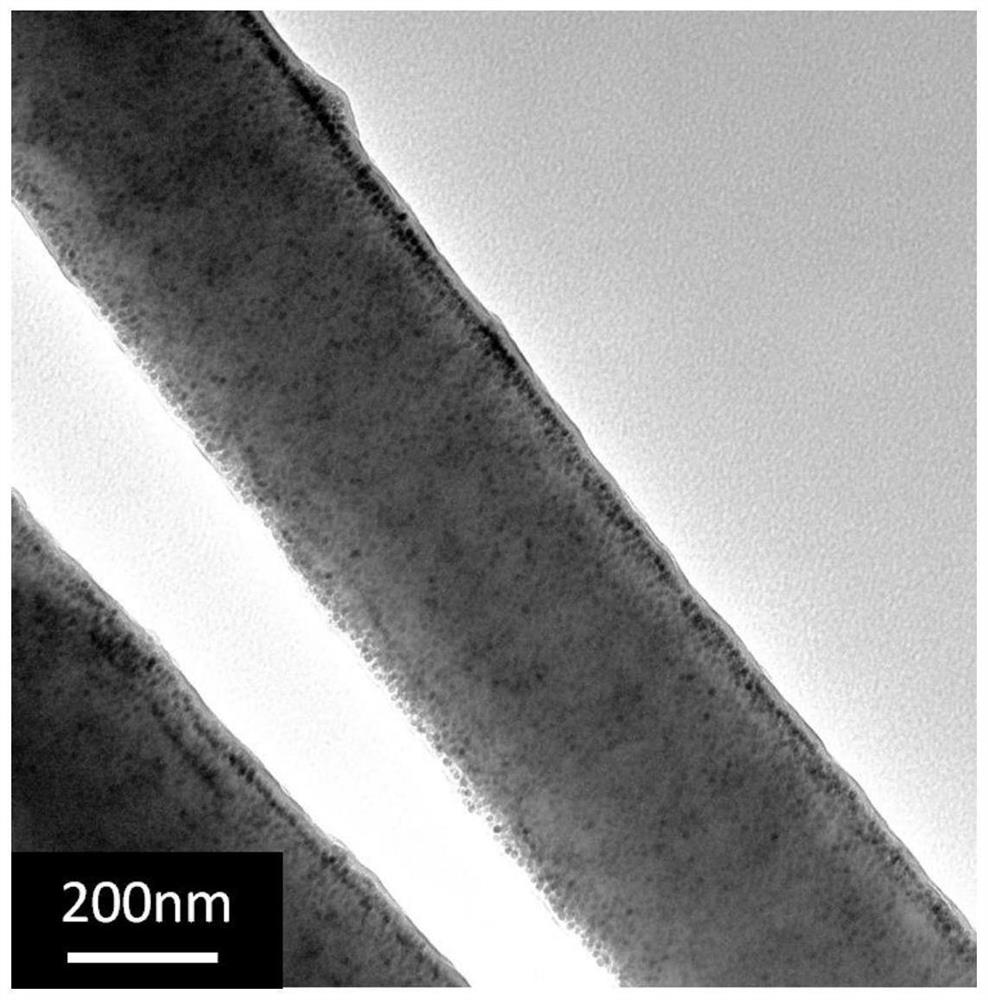

[0092] When the particle size increases to 80nm, a single particle arrangement can be achieved. Since the ligands on the surface of the particles were not treated, the distance between the particles was too large and the arrangement was not tight.

[0093] 1. Take 1ml of synthesized 80nm Fe 3 o 4 The magnetic nanoparticles were added to the PAN (13wt%) spinning solution, ultrasonically oscillated for 10 minutes, and vortex was rotated and mixed for 20 minutes. Wherein, the preparation method of PAN spinning solution is the same as that of Comparative Example 1.

[0094] 80 nm magnetic nanoparticles were synthesized as follows: Iron(III) acetylacetonate (0.706 g, 2 mM) was added to a mixture of oleic acid (1.129 g, 4 mM) and benzyl ether (10.40 g, 10 mL). The mixture solution was degassed at room temperature for 1 hour. The solution was then heated to 290°C at a rate of 15°C / min under vigorous magnetic stirring. It should be noted that the stirring speed should be fast to ...

Embodiment 3

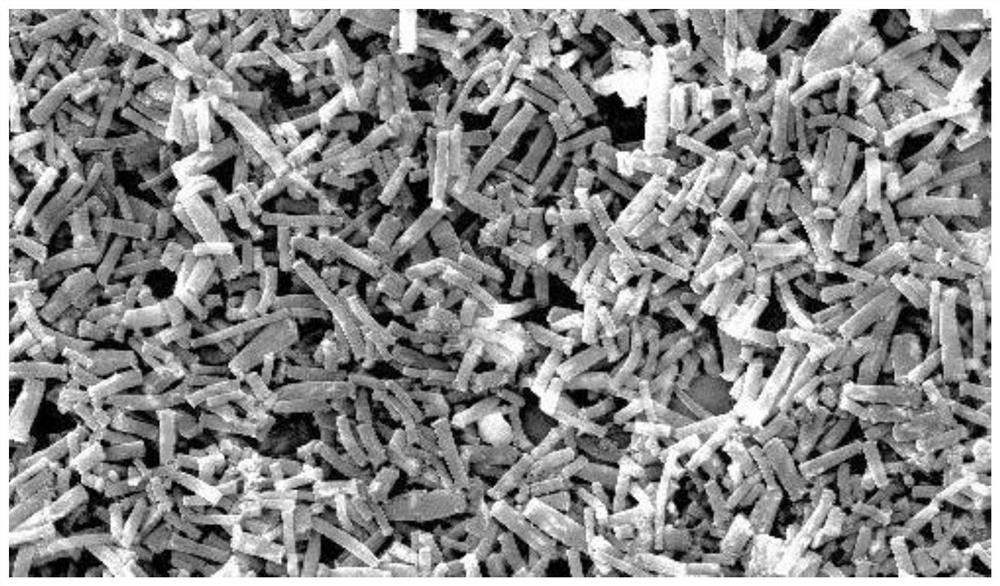

[0099] Using 110nm large particles, after the surface ligand washing treatment, the nanoparticles are closely arranged along the fiber axis, the stirring effect is obvious, and the effective stirring distance is the largest.

[0100] 1. Take 100ml synthesized 110nm Fe 3 o 4 The magnetic nanoparticles were added to the PAN (13wt%) spinning solution, ultrasonically oscillated for 10 minutes, and vortex was rotated and mixed for 20 minutes. Wherein, the preparation method of PAN spinning solution is the same as that of Comparative Example 1.

[0101] 110 nm magnetic nanoparticles were synthesized as follows: Iron(III) acetylacetonate (0.706 g, 2 mM) was added to a mixture of oleic acid (1.129 g, 4 mM) and benzyl ether (5.2 g, 10 mL). The mixture solution was degassed at room temperature for 1 hour. The solution was then heated to 290°C at a rate of 15°C / min under vigorous magnetic stirring. It should be noted that the stirring speed should be fast to prevent the magnetic inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com