A method for producing novel soil conditioning functional materials using industrial solid waste

A functional material and soil conditioning technology, applied in the field of environmental protection, can solve the problem of high preparation cost, and achieve the effects of controlling salinity, restoring natural features and enhancing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

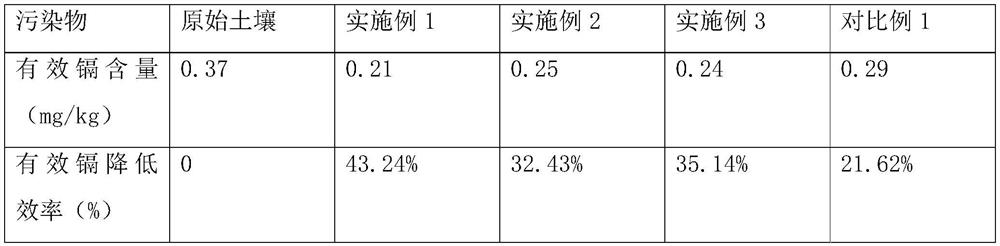

Examples

Embodiment 1

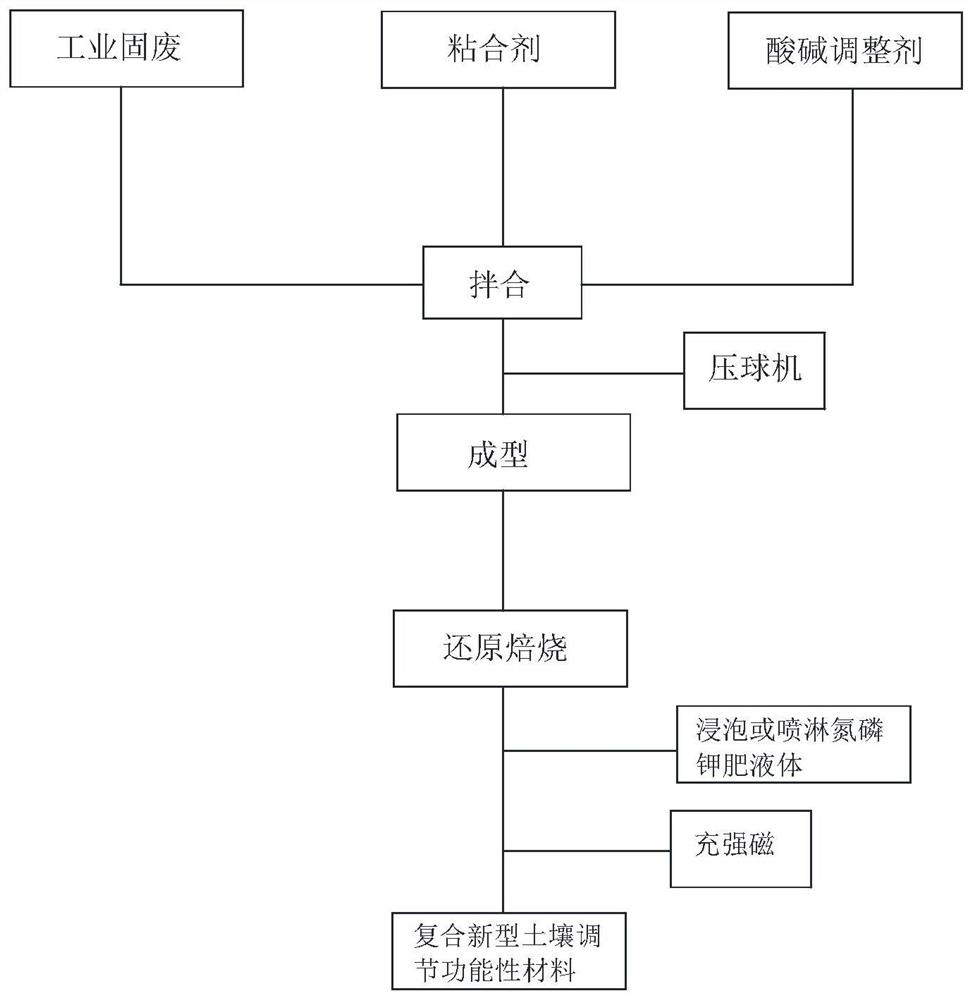

[0046] A method of utilizing industrial solid waste to produce novel soil conditioning functional materials, comprising the following steps:

[0047] (1) mixing

[0048] The red mud, the binder and the acid mineral are selected as raw materials, the red mud, the binder and the acid mineral are mixed in a ratio of 92:5:3 by weight, and high-speed strong mechanical mixing is carried out to obtain the mixture. Wherein, the adhesive is composed of bentonite, corn dextrin and plant rhizome, wherein the weight ratio of bentonite, corn dextrin and plant root is 3:1:1. Acid minerals can choose sulfuric acid slag or acid mud.

[0049](2) Molding

[0050] The mixture prepared in step (1) is pressed into capsule-like particles by a powerful briquetting machine, and the pressure of the briquetting machine is 500 MPa.

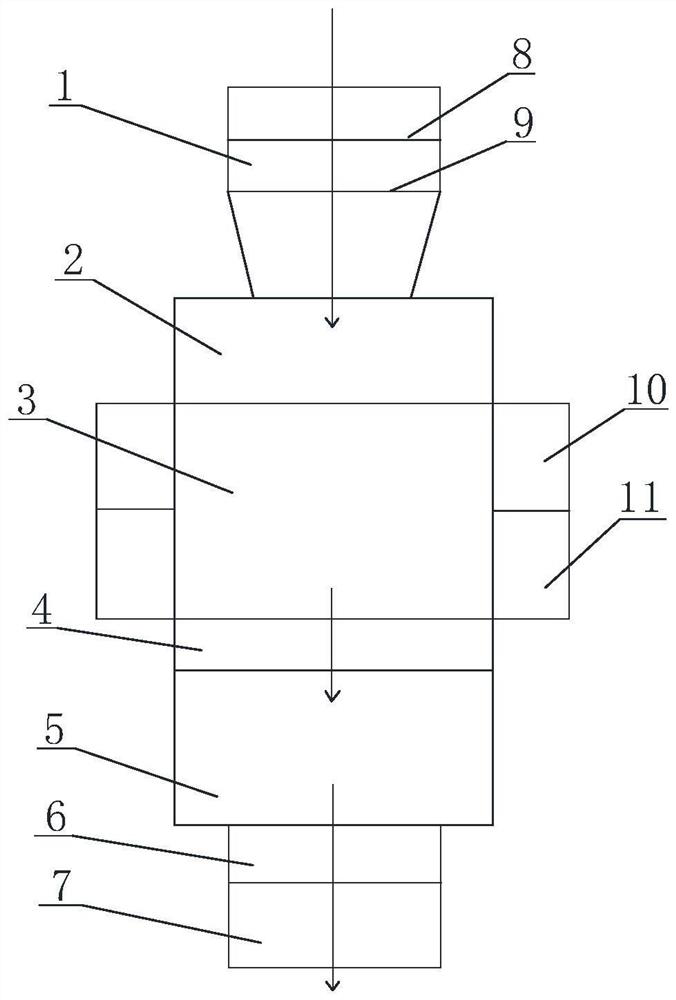

[0051] (3) Reduction roasting

[0052] The capsule-shaped particles obtained in step (2) are roasted and reduced by using a mineral roasting and reducing device. The mi...

Embodiment 2

[0061] The preparation method is the same as that in Example 1, the difference is that: fly ash, binder and oxalic acid are selected as raw materials, and the weight ratio of fly ash, binder and oxalic acid is 95:3:2, wherein the binder The invention is composed of bentonite, corn dextrin and plant rhizome, wherein the weight ratio of bentonite, corn dextrin and plant rhizome is 3:1:2.

Embodiment 3

[0063] The preparation method is the same as in Example 1, the difference is that the sulfuric acid slag, binder and slaked lime are mixed in a ratio of 95:3:5 in parts by weight; the parts by weight of bentonite, corn dextrin and plant rhizome in the binder are The ratio is 3:2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com