Gangue paste cementing material, preparation method thereof, gangue paste filling material and preparation method thereof

A technology of cementing material and gangue, which is applied in the field of mine filling, can solve the problems of high raw material cost and low strength, and achieve the effects of reduced production cost, high economic value, and improved coagulation strength and coagulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

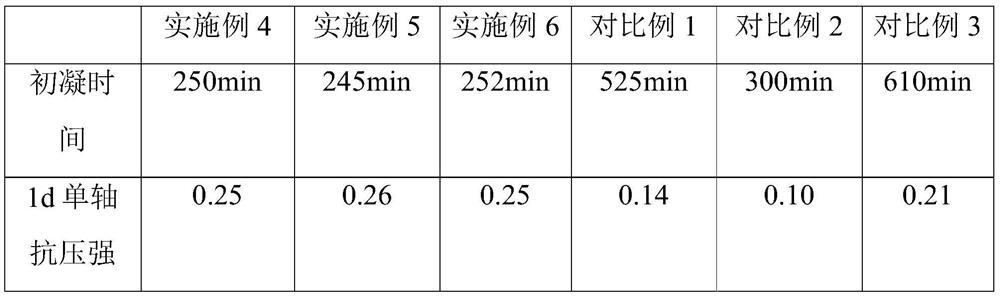

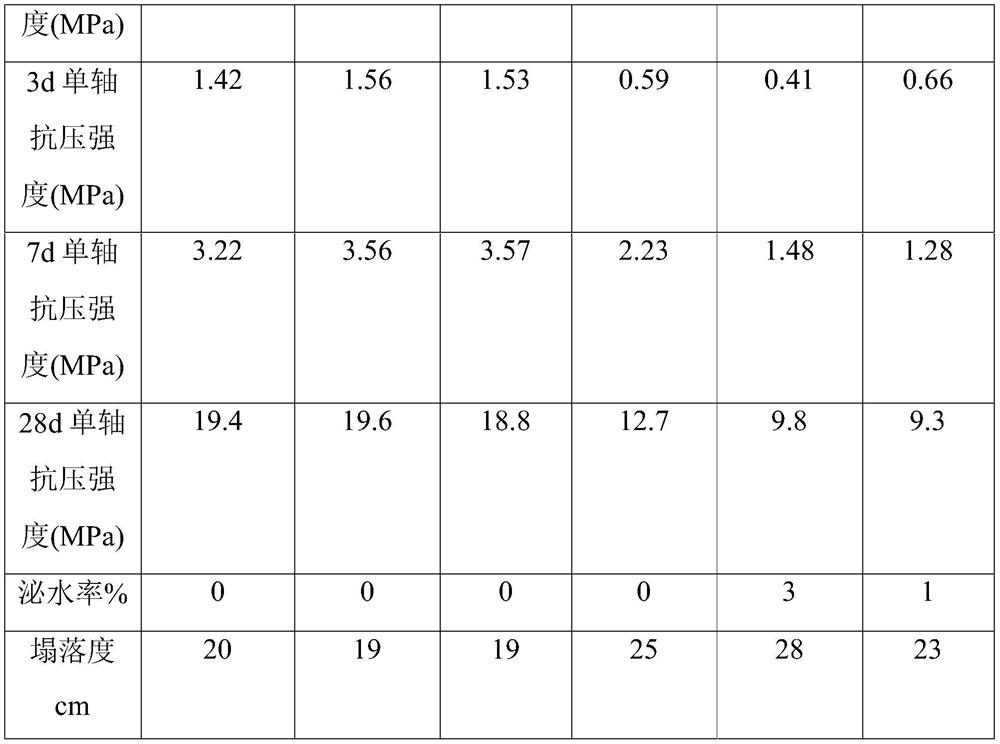

Examples

Embodiment 1

[0035] A gangue paste cementing material is composed of the following components in parts by mass:

[0036] 20 parts of Portland cement clinker, 2 parts of sulphoaluminate cement clinker, 5 parts of modified gypsum, 60 parts of mineral powder, 5 parts of limestone powder, 0.2 part of sodium silicate, and 2 parts of admixture.

[0037] Among them, the fineness of Portland cement clinker is between 350-400 mesh;

[0038] Sulphoaluminate cement clinker is mixed with bauxite, limestone, gypsum and boric acid, calcined at 1300°C, and ground to a specific surface area of ≥460m 2 / kg obtained, the mixed mass ratio of the bauxite, limestone, gypsum and boric acid is 30:45:8:1, and the content of alumina in the sulphoaluminate cement clinker is 29%;

[0039] The admixture is composed of sodium hydroxymethylcellulose, polyacrylamide, high-efficiency water reducer and polycarboxylate with a mass ratio of 2:1:1:1; the high-efficiency water reducer is composed of wood Calcium sulfonate...

Embodiment 2

[0045] A gangue paste cementing material is composed of the following components in parts by mass:

[0046] 25 parts of Portland cement clinker, 3 parts of sulphoaluminate cement clinker, 8 parts of modified gypsum, 65 parts of mineral powder, 8 parts of limestone powder, 0.25 parts of sodium silicate, and 3 parts of admixture.

[0047] Among them, the fineness of Portland cement clinker is between 350-400 mesh;

[0048] Sulphoaluminate cement clinker is mixed with bauxite, limestone, gypsum and boric acid, calcined at 1350°C, and ground to a specific surface area of ≥460m 2 / kg, the mixed mass ratio of the bauxite, limestone, gypsum and boric acid is 36:50:15:1.5, and the content of alumina in the sulphoaluminate cement clinker is 32%;

[0049] The admixture is composed of sodium hydroxymethylcellulose, polyacrylamide, high-efficiency water reducer and polycarboxylate with a mass ratio of 2.5:1.5:1.5:1.5; the high-efficiency water reducer is made of wood with a mass ratio o...

Embodiment 3

[0055] A gangue paste cementing material is composed of the following components in parts by mass:

[0056] 30 parts of Portland cement clinker, 4 parts of sulphoaluminate cement clinker, 10 parts of modified gypsum, 70 parts of mineral powder, 10 parts of limestone powder, 0.3 parts of sodium silicate, and 4 parts of admixture.

[0057] Among them, the fineness of Portland cement clinker is between 350-400 mesh;

[0058] Sulphoaluminate cement clinker is mixed with bauxite, limestone, gypsum and boric acid, calcined at 1400°C, and ground to a specific surface area of ≥460m 2 / kg obtained, the mixed mass ratio of the bauxite, limestone, gypsum and boric acid is 42:58:20:2, and the content of alumina in the sulphoaluminate cement clinker is 35%;

[0059] The admixture is composed of sodium hydroxymethylcellulose, polyacrylamide, high-efficiency water reducer and polycarboxylate with a mass ratio of 3:2:2:2; the high-efficiency water reducer is made of wood with a mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com