Novel stacking device and stacking method

A stacking device and stacking technology, applied in the field of new stacking devices, can solve the problems of production environment pollution, waste of workshop space, pollutants or foreign objects entering the workshop, etc., so as to reduce workshop environmental pollution, save stacking space, protect The effect of the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

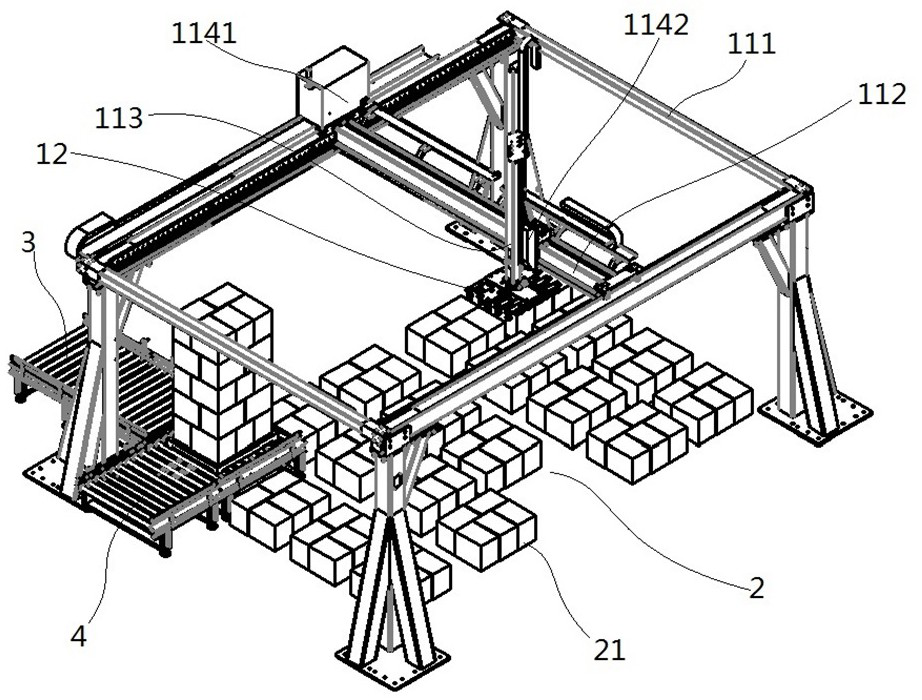

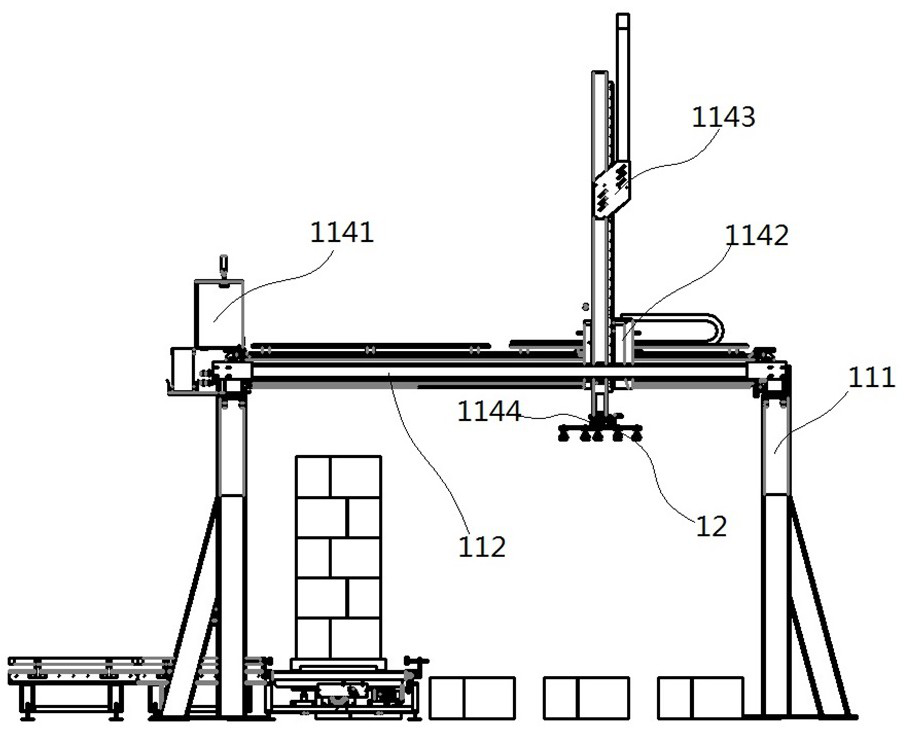

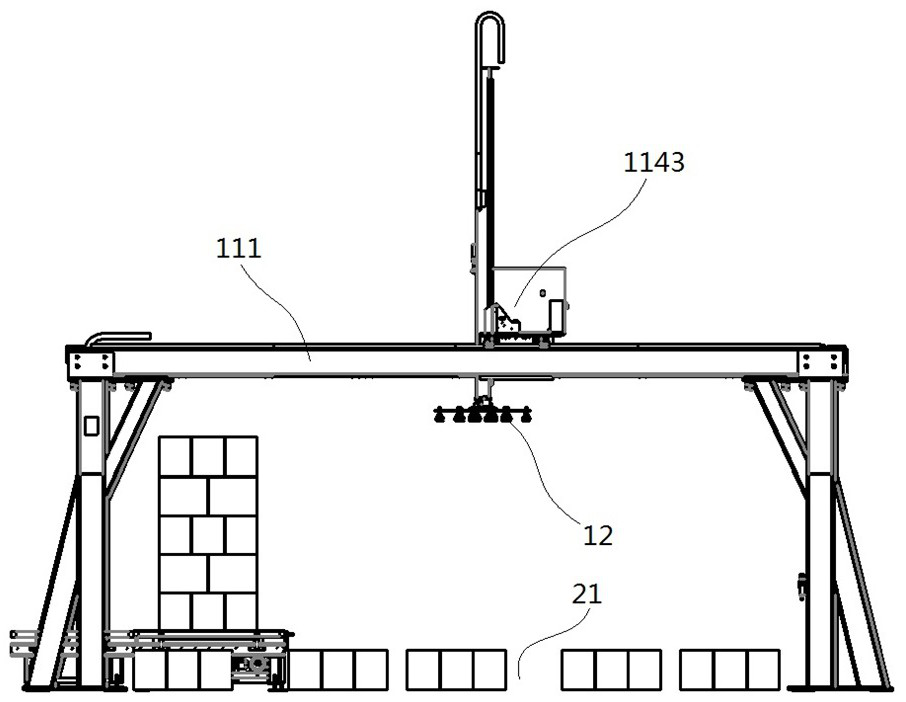

[0046] First, combine the Figure 1~5 The novel palletizing device according to the embodiment of the present invention is described, which is used for palletizing products onto pallets and has a wide range of application scenarios.

[0047] like figure 1 , 5 As shown, the new palletizing device according to the embodiment of the present invention has a palletizing module 1 , a product stacking module 2 , a stacking station 3 , a stacking station 4 and a control module 5 . Wherein, the control module 5 is electrically connected to the palletizing module 1, the stacking station 3 and the stacking station 4, and the control module 5 communicates with external enterprise production management systems such as ERP and SAP and / or warehouse management systems, including It is not limited t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com