Automatic cutting device for aluminum profile processing

An automatic cutting device and aluminum profile processing technology, applied in the direction of sawing machine, metal processing equipment, sawing machine accessories, etc., can solve the problems of low processing efficiency, short service life, low safety performance, etc., to improve production efficiency and The effect of production quality, liberating manpower, and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

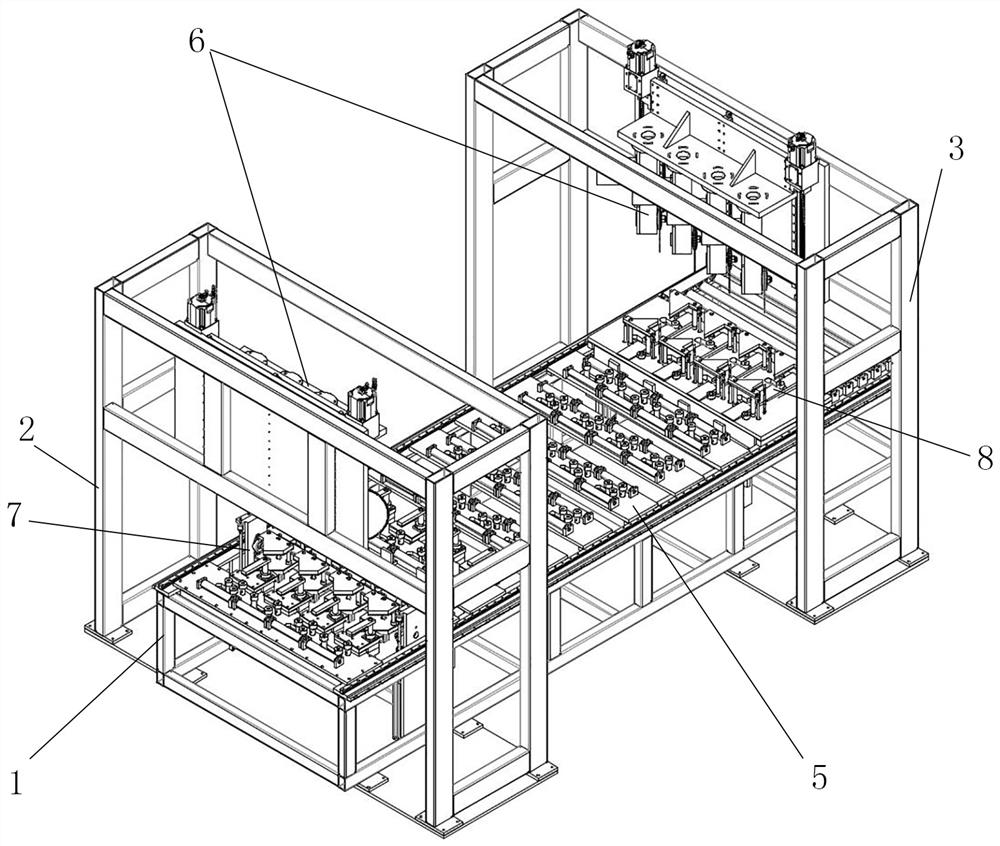

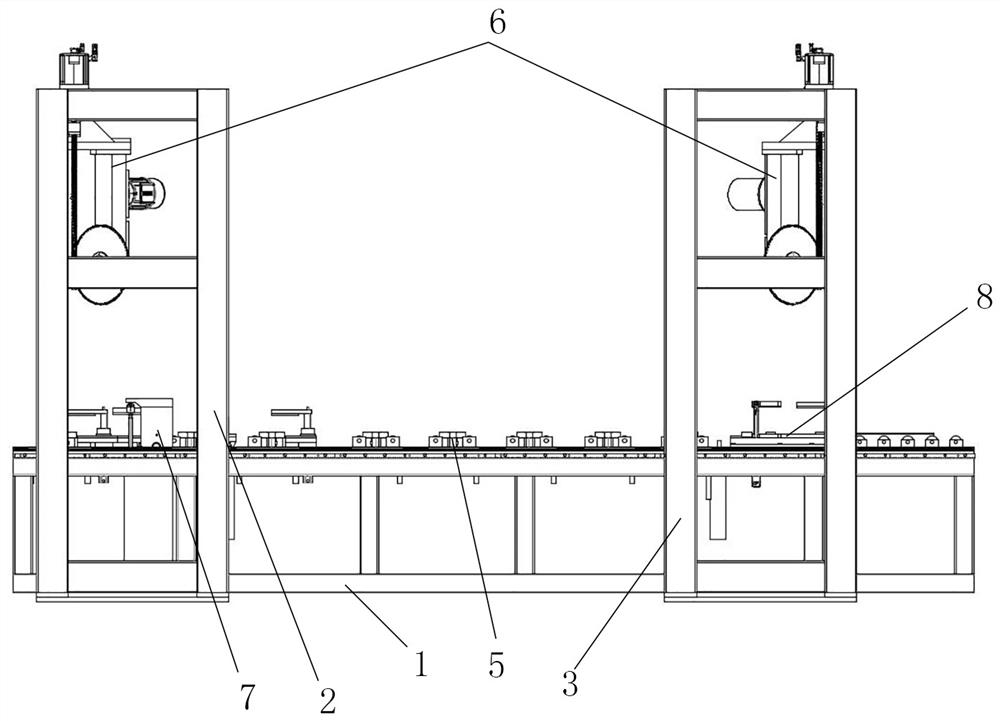

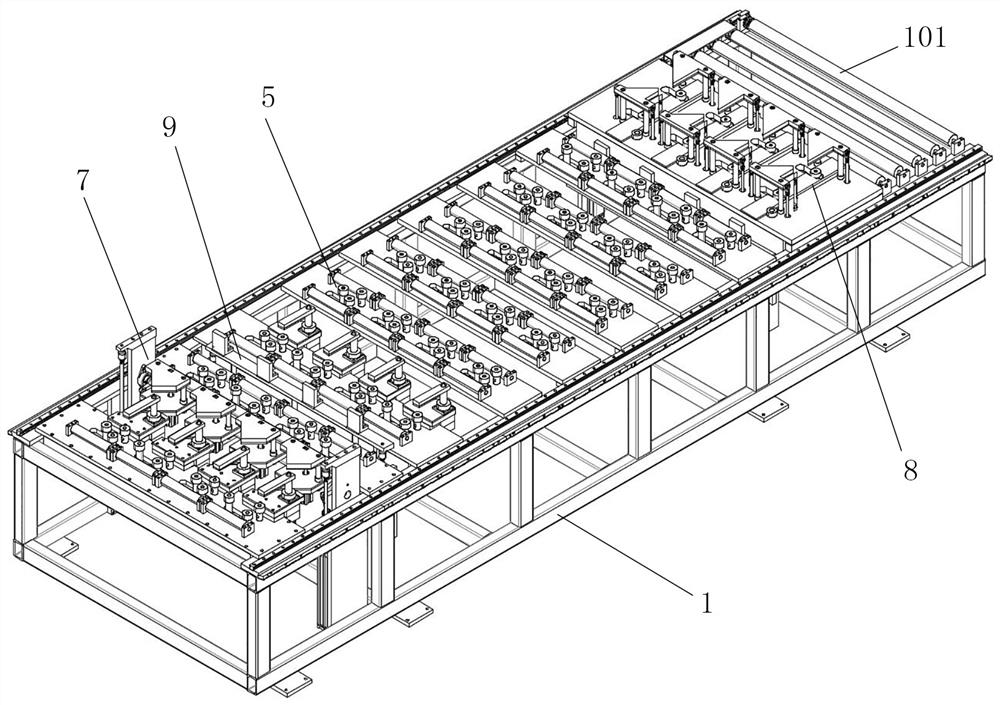

[0036] As shown in the figure: an automatic cutting device for aluminum profile processing, including a conveying frame 1, an end cutting frame 2, a cutting frame 3 and a pushing cart 4, and the pushing cart 4 is installed on the conveying frame 1 and can be transported along the The frame 1 moves, and the conveying frame 1 is equipped with a clamping mechanism for clamping aluminum profiles. Along the processing and conveying direction, the conveying frame 1 is provided with a plurality of supporting and clamping mechanisms 5 for horizontally supporting and laterally movable clamping of aluminum profiles. , the end cutting frame 2 and the slitting frame 3 are all erected above the conveying frame 1, and a plurality of cutting parts 6 for cutting aluminum profiles are installed on the end cutting frame 2 and the slitting frame 3, and the aluminum profiles are composed of multiple After a supporting and clamping mechanism 5 is horizontally supported and movable and clamped, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com